High-density boron carbide ceramic material and pressureless sintering preparation method thereof

A boron carbide ceramic and boron carbide technology are applied in the field of high-density boron carbide ceramic materials and the preparation of pressureless sintering, which can solve the problems of inability to bond boron carbide and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

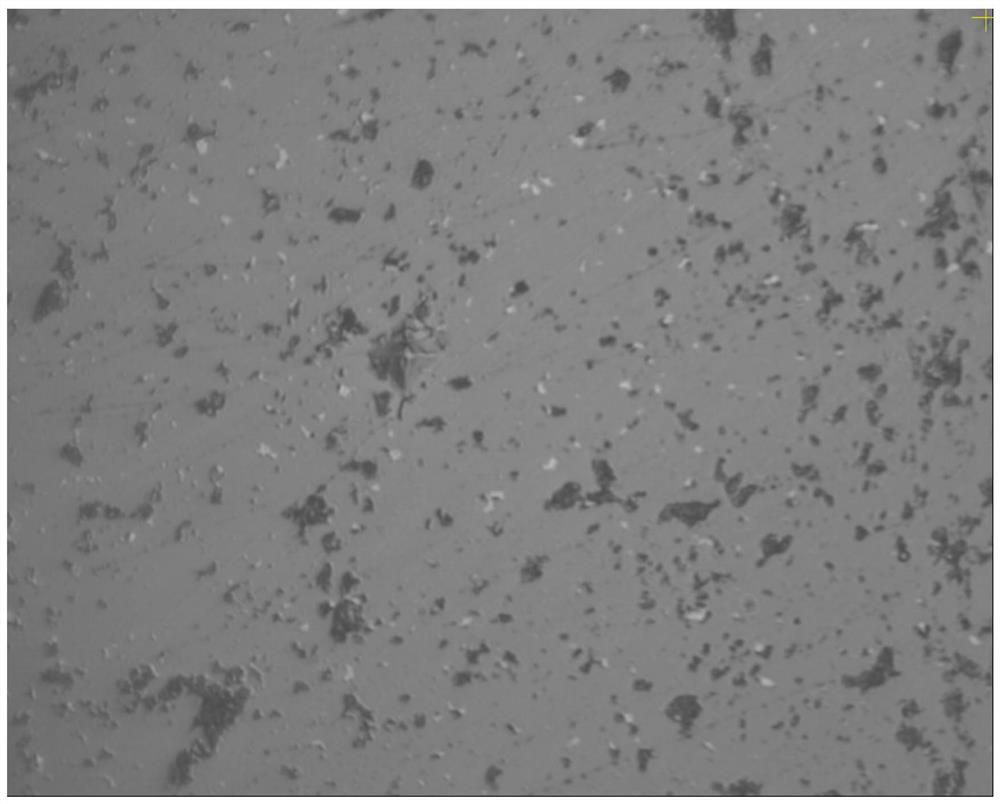

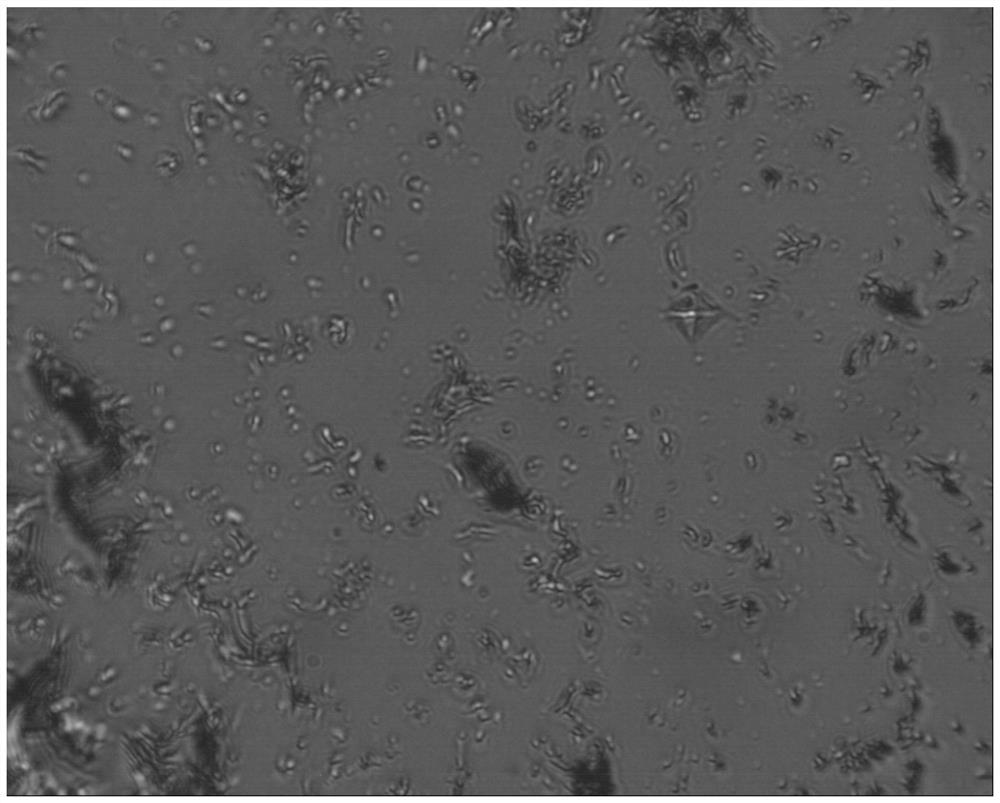

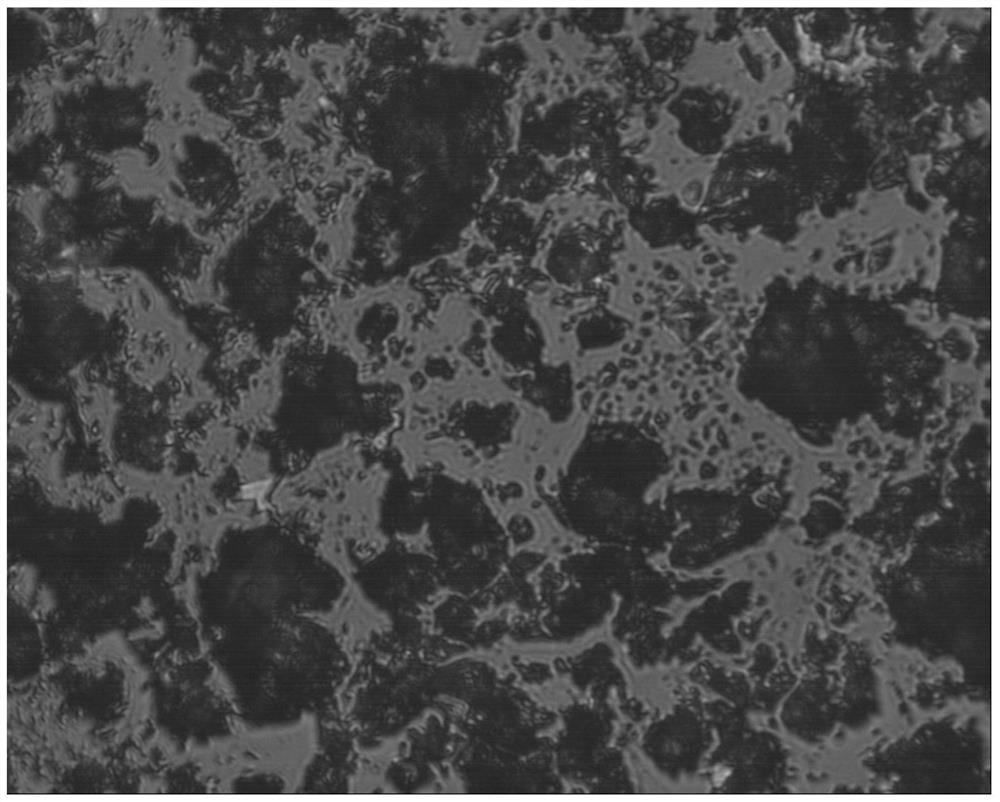

Image

Examples

Embodiment 1

[0024] This embodiment provides a method for preparing high-density boron carbide ceramics by pressureless sintering. The raw materials are weighed according to the mass percentage of the following conditions: boron carbide 86%, chromium disilicide 3%, silicon carbide 3%, aluminum 1%, polyimide Amine 7%, carbon black 1%;

[0025] Mix the above-mentioned materials except polyimide and put them into a planetary ball mill for ball milling for 40 hours; the ratio of solid to liquid is 1:1, the ratio of ball to material is 6:1, and the speed of the ball mill is 600r / min. After ball milling, polyimide is added to the material, mixed evenly, dried, sieved through a 50-mesh sieve, and placed in a blower drying box for low-temperature drying to obtain a fine powder of the mixture.

[0026] After the mixture powder is pressed and molded under a molding pressure of 200MPa, the plain embryo is made, and then the plain embryo is subjected to pressureless vacuum sintering. During the sinter...

Embodiment 2

[0030] This embodiment provides a method for preparing high-density boron carbide ceramics by pressureless sintering. The raw materials are weighed according to the mass percentage of the following conditions: boron carbide 84%, chromium disilicide 4%, silicon carbide 6%, aluminum 1.5%, polyimide Amine 3%, carbon black 1.5%;

[0031] Mix the above-mentioned materials except polyimide and put them into a planetary ball mill for ball milling for 25 hours; the ratio of solid to liquid is 1:2, the ratio of ball to material is 6:1, and the speed of the ball mill is 500r / min. After ball milling, polyimide is added to the material, mixed evenly, dried, sieved through a 70-mesh sieve, and placed in a blower drying box for low-temperature drying to obtain a fine powder of the mixture.

[0032] After the mixture is pressed and molded at a molding pressure of 190MPa, the plain embryo is obtained, and the plain embryo is subjected to pressureless vacuum sintering. During the sintering pro...

Embodiment 3

[0036] This embodiment provides a method for preparing high-density boron carbide ceramics by pressureless sintering. The raw materials are weighed according to the mass percentage of the following conditions: boron carbide 82%, chromium disilicide 5%, silicon carbide 7%, aluminum 0.5%, polyimide Amine 5%, carbon black 0.5%;

[0037] Mix the above-mentioned materials except polyimide and put them into a planetary ball mill for ball milling for 30 hours; the ratio of solid to liquid is 1:1, the ratio of ball to material is 3:1, and the speed of the ball mill is 500r / min. After ball milling, polyimide is added to the material, mixed evenly, dried, sieved through a 70-mesh sieve, and placed in a blower drying box for low-temperature drying to obtain a fine powder of the mixture.

[0038] After the mixture powder is pressed and molded with a molding pressure of 220MPa, the plain embryo is obtained, and then the plain embryo is subjected to pressureless vacuum sintering. During the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com