MXene coating prepared based on spin-coating method and application of MXene coating in hydrogen resistance process

A spin-coating method and coating technology, applied in the coating, metal material coating process, superimposed layer plating and other directions, can solve the problems of easy peeling off of the hydrogen barrier coating, harsh preparation conditions, poor thermal stability, etc. Good hydrogen permeability, simple operation steps, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

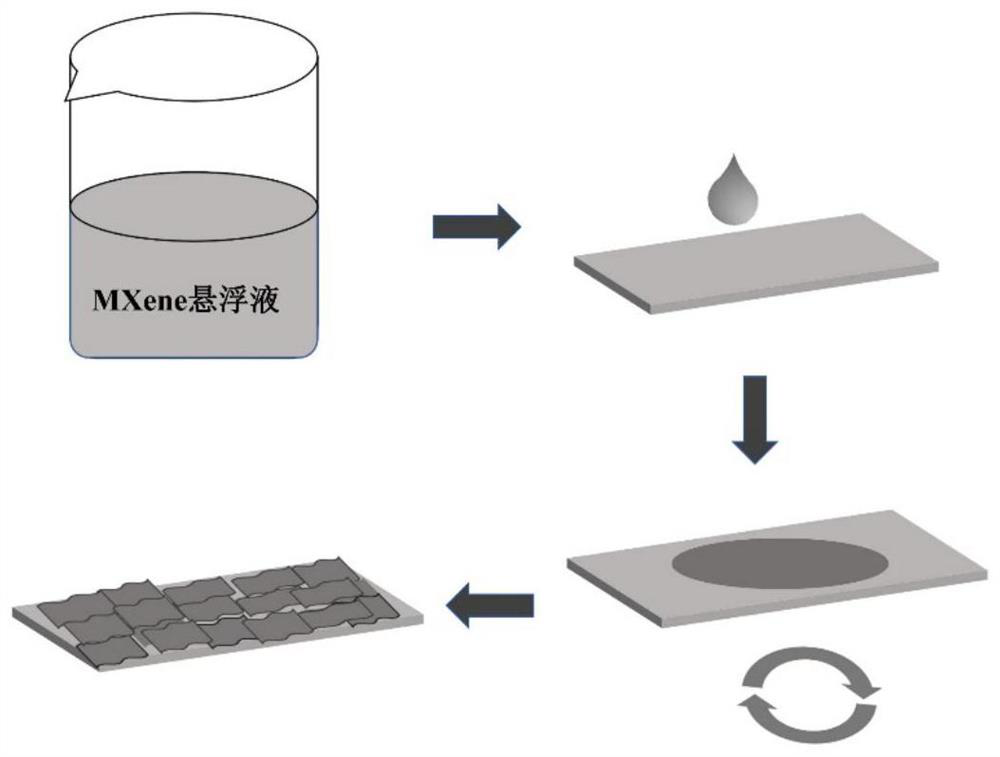

[0041] In this embodiment, the attached figure 1 The spin-coating method shown, spin-coated on the surface of pipeline steel to prepare Ti 3 C 2 T x Hydrogen barrier coating, comprising the following steps:

[0042] (1) Choose X70 pipeline steel as the base material, use 200#, 400#, 800# SiC sandpaper to grind the sample step by step, use chemical reagents to corrode and polish, use 3000# SiC sandpaper to polish again, and use wool ball head to cooperate with polishing The paste polishes the substrate to a mirror finish. The polished substrate was cleaned with deionized water and ultrasonically cleaned in ethanol for 10 min, then the sample was wiped clean with a dust-free cloth, and air-dried for 3 min.

[0043] (2) Put Ti 3 C 2 (OH) 2 The MXene suspension was diluted to 4 mg / mL with deionized water and dispersed ultrasonically for 10 minutes. The diluted MXene colloid had obvious Tyndall effect under the irradiation of a laser pointer;

[0044] (3) Use as attached f...

Embodiment 2

[0052] In this embodiment, the attached figure 1 The spin-coating method shown, spin-coated on the surface of pipeline steel to prepare Ti 3 C 2 T x Hydrogen barrier coating, comprising the following steps:

[0053] (1) Choose X70 pipeline steel as the base material, use 200#, 400#, 800# SiC sandpaper to grind the sample step by step, use chemical reagents to corrode and polish, use 3000# SiC sandpaper to polish again, and use wool ball head to cooperate with polishing The paste polishes the substrate to a mirror finish. The polished substrate was cleaned with deionized water and ultrasonically cleaned in ethanol for 10 min, and then the sample was wiped clean with a dust-free cloth and air-dried.

[0054] (2) Put Ti 3 C 2 (OH) 2 The MXene suspension was diluted to 2 mg / mL with deionized water and dispersed ultrasonically for 10 minutes. The diluted MXene colloid had obvious Tyndall effect under the irradiation of a laser pointer;

[0055] (3) Use as attached figure 1...

Embodiment 3

[0062] In this embodiment, the attached figure 1 The spin-coating method shown, spin-coated on the surface of pipeline steel to prepare Ti 3 C 2 T x Hydrogen barrier coating, comprising the following steps:

[0063] (1) Choose X70 pipeline steel as the base material, use 200#, 400#, 800# SiC sandpaper to grind the sample step by step, use chemical reagents to corrode and polish, use 3000# SiC sandpaper to polish again, and use wool ball head to cooperate with polishing The paste polishes the substrate to a mirror finish. The polished substrate was cleaned with deionized water and ultrasonically cleaned in ethanol for 10 min, and then the sample was wiped clean with a dust-free cloth and air-dried.

[0064] (2) Put Ti 3 C 2 (OH) 2 The MXene suspension was diluted to 4 mg / mL with deionized water and dispersed by ultrasonic wave for 10 minutes. The diluted MXene colloid had obvious Tyndall effect under the irradiation of a laser pointer;

[0065] (3) Place the X70 pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com