Hybrid conductor hydrogen permeation membrane material as well as preparation method and application thereof

A technology of mixed conductors and hydrogen permeable membranes, applied in separation methods, semipermeable membrane separations, chemical instruments and methods, etc., can solve problems that restrict large-scale production and industrial applications, and have not yet developed mixed hydrogen permeable membrane materials. Good long-term chemical stability, improved hydrogen permeability, and improved proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A fluorite-type tungstic acid-based mixed conductor hydrogen permeable membrane material La with in-situ desolubilization of Pd metal nanoparticles 5.5 (W 0.6 Mo 0.4 ) 0.95 Pd 0.05 O 11.25-δ (LWMPd), wherein δ=0~1, wherein the preparation method comprises the following steps:

[0046] (1) Weigh 16.432g La respectively 2 O 3 , 2.424g WO 3 , 1.004g MoO 3 , 0.1122g PdO, add 20mL ethanol after preliminary mixing, carry out ball milling at a speed of 400r / min, take out and dry naturally after 48h.

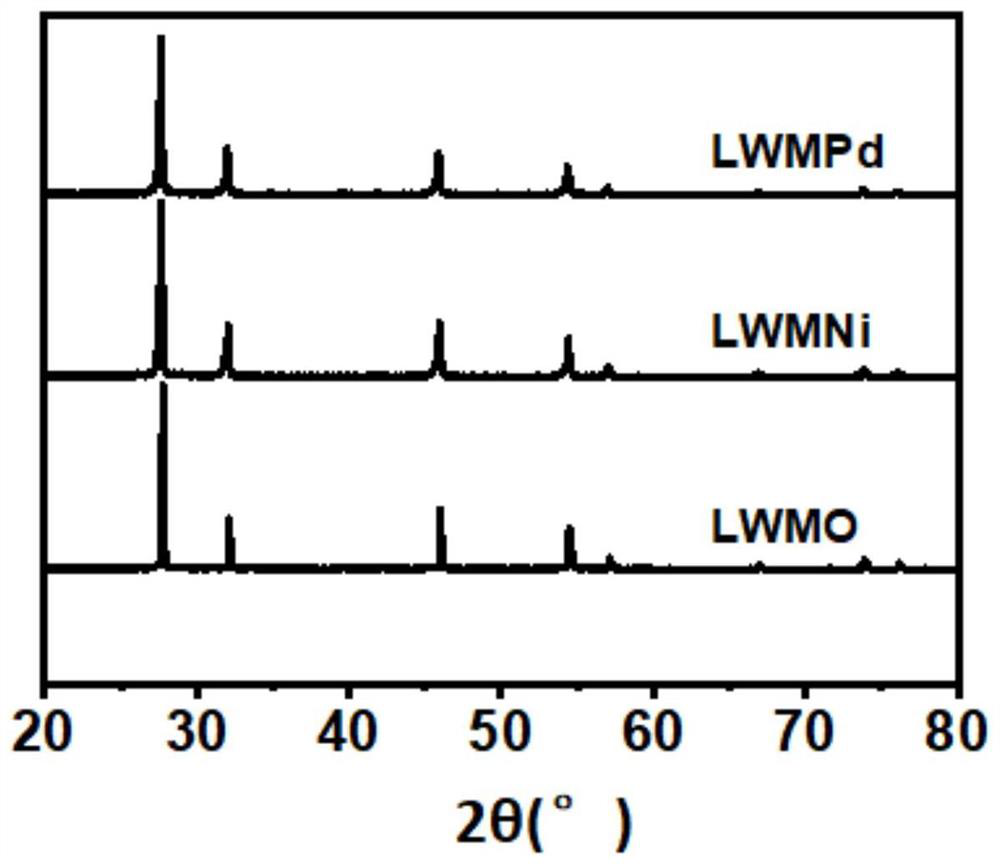

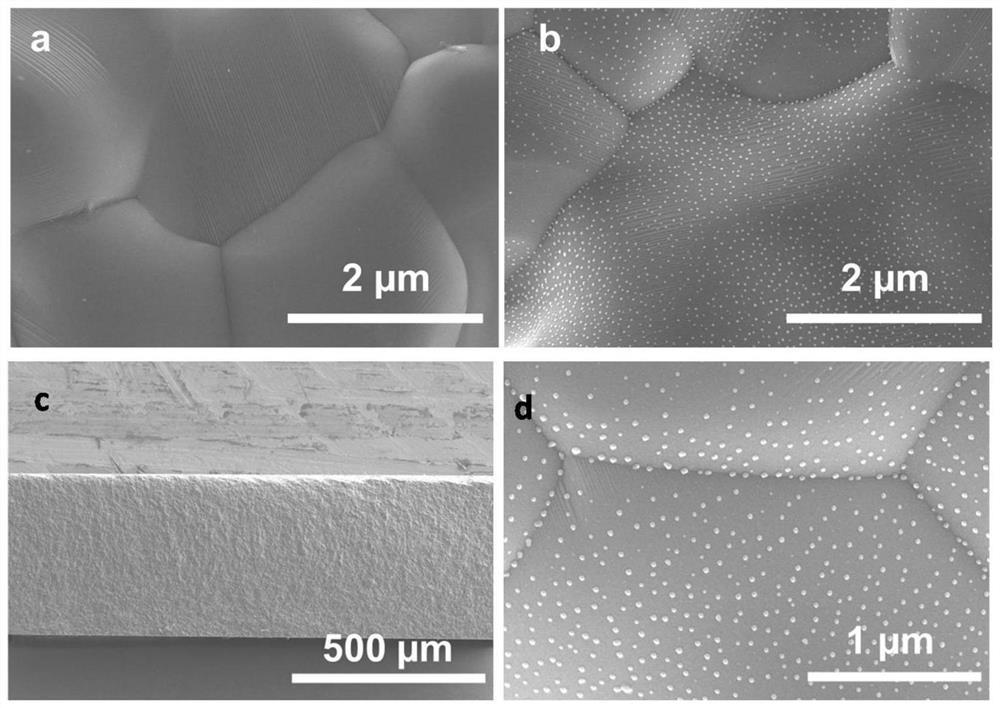

[0047] (2) The mixed raw material powder obtained by ball milling is placed in a high temperature muffle furnace and heated to 1100°C at a heating rate of 2°C / min, kept for 10 hours, and then lowered to room temperature at a rate of 2°C / min to obtain LWMPd Phase powder. The obtained LWMPd powder is subjected to phase analysis, and the results are as follows figure 1 As shown, the material maintains the original fluorite structure after doping with palladium element, an...

Embodiment 2

[0052] A fluorite-type tungstic acid-based mixed conductor hydrogen permeable membrane material La with in-situ desolubilization of Ni metal nanoparticles 5.5 (W 0.6 Mo 0.4 ) 0.95 Ni 0.05 O 11.25-δ (LWMNi) wherein δ=0~1, and its preparation method comprises the following steps:

[0053] (1) Weigh 16.468g La respectively 2 O 3 , 2.429g WO 3 , 1.005g MoO 3 , 0.0686g NiO, add 20mL ethanol after preliminary mixing, carry out ball milling at a speed of 400r / min, take out and dry naturally after 48h.

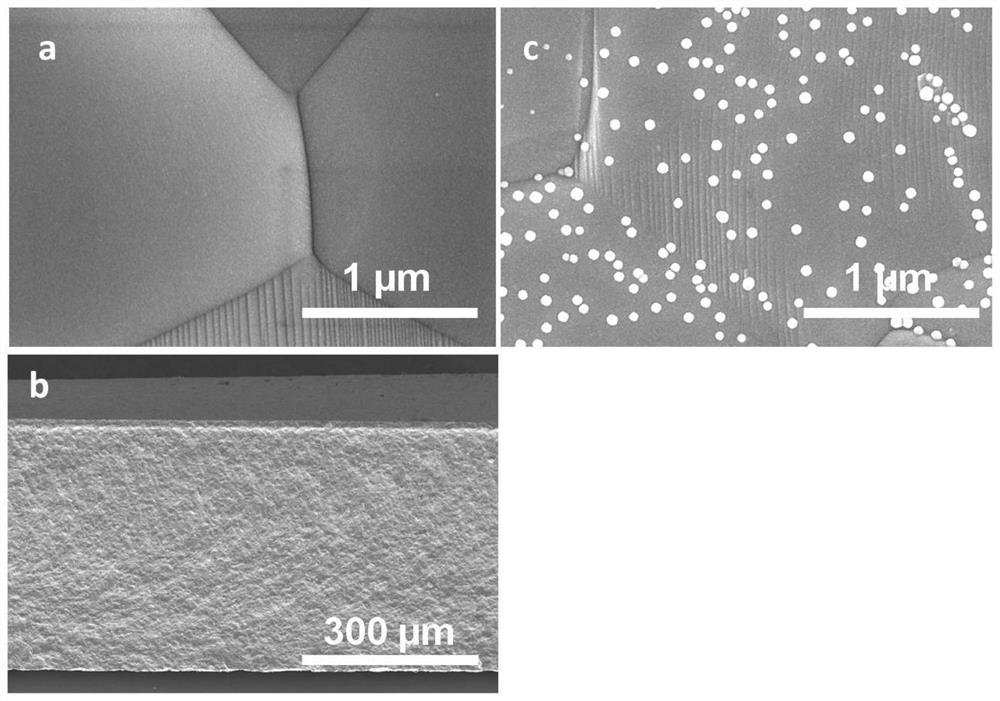

[0054] (2) The mixed raw material powder obtained by ball milling is placed in a high temperature muffle furnace and heated to 1100°C at a heating rate of 2°C / min, kept for 10 hours, and then lowered to room temperature at a rate of 2°C / min to obtain LWMNi composition. Phase powder. The obtained LWMNi powder is subjected to phase analysis, and the results are as follows figure 1 As shown in the figure, after doping with nickel element, the material maintains the original fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com