Hydrogen-absorbing device for hydrogen-sensitive hybrid integrated circuit and preparation method thereof

A hybrid integrated circuit, sensitive technology, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of high cost, low hydrogen absorption efficiency/rate, poor use robustness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

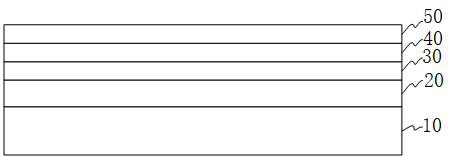

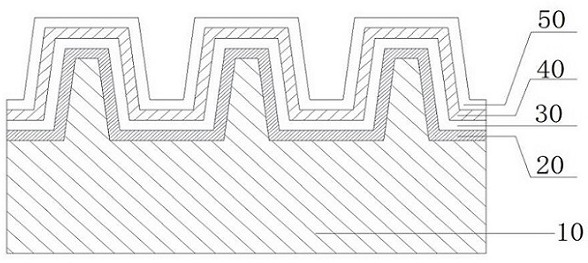

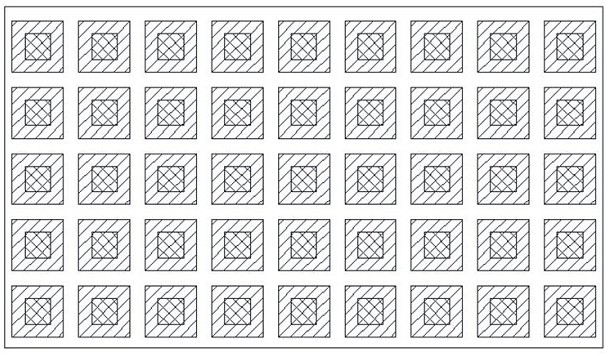

[0131]A 0.3mm-thick alumina ceramic sheet is used as a carrier, and a cuboid microcone of 0.8mm×0.8mm×0.1mm (length×width×height) and an inclination angle of 80 degrees is formed on its surface to enhance the specific surface, and the entire surface passes through Chemical roughening further enhances the specific surface, such as Figure 3a shown. Then, the surface film layer was prepared by magnetron sputtering process. The surface of the carrier was covered with 20μm 4N (purity 99.99%) metal titanium as the hydrogen absorption layer, and the hydrogen absorption layer was covered with 1μm thick cobalt as the selective hydrogen permeability layer. The selective hydrogen permeation layer is covered with palladium with a thickness of 10 nm as a protective layer, and finally, a layer of PDMS with a thickness of 10 μm is sprayed on the surface as an anti-particle peeling layer, such as Figure 3b shown.

[0132] in Figure 3b Represents the schematic structure of the surface fi...

Embodiment 2

[0134] The zero-grade sponge titanium of 10mm×5mm×1mm (length×width×height) is used as the carrier and also serves as the hydrogen absorption layer, and a layer of metal palladium with a thickness of 500nm is electroplated on the surface and hole wall as the selective hydrogen permeation layer and as the protective layer. ,like Figure 4a Then, a 15μm polystyrene (Polystyrene: MW=280K) polymer film is sprayed on the surface as an anti-particle peeling layer. In this embodiment, the selective hydrogen permeation layer and the protective layer are made of the same metal palladium. Do.

[0135] in, Figure 4b It means that the zero-grade sponge titanium includes: 500nm-thick metal palladium as the selective hydrogen permeation layer and protective layer, and 15μm-thick polystyrene (Polystyrene: MW=280K) polymer film anti-particle shedding layer.

Embodiment 3

[0137] Using 3N5 (purity 99.95%) titanium tape (thickness 0.2mm) as the carrier and hydrogen absorption layer, the surface is processed by surface enhancement to form micro-cone grooves with a height of about 50 microns to enhance the specific surface, such as Figure 5a As shown; re-cladding is covered with 0.5 μm thick cobalt as a selective hydrogen permeation layer and 10 nm thick palladium as a protective layer, without an anti-particle peeling layer.

[0138] Figure 5b The schematic structure of the surface film layer prepared on the basis of the titanium carrier is shown, including a cobalt selective hydrogen permeation layer with a thickness of 0.5 μm and a palladium protective layer with a thickness of 10 nm.

[0139] The reference numeral 12 denotes a micro-cone groove structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com