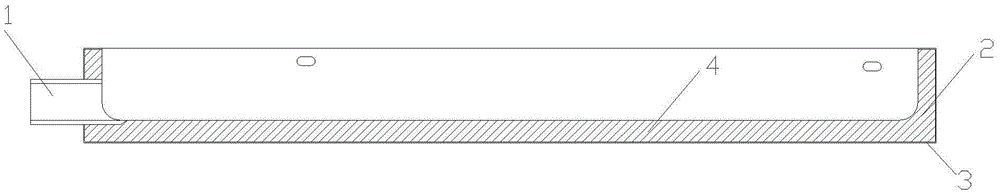

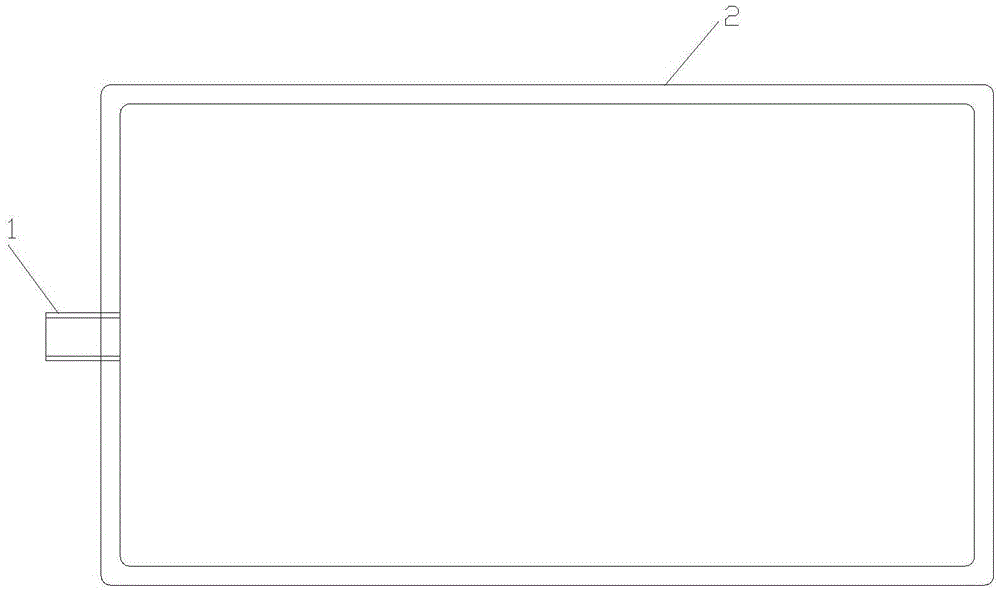

Water pond and production process thereof

A production process and water tray technology, which is applied in the field of water tray and its production process, can solve the problems of limited thermal insulation effect of PE thermal insulation cotton, easy scratching of PE moisturizing cotton, affecting thermal insulation effect, etc., so that it is not easy to be scratched, solves the problem Easily deformed by welding and light in weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The polyurethane mixture includes the following components by weight: 90 parts of polyether polyol, 30 parts of perlite, 25 parts of chain extender, 8 parts of foaming agent, 4 parts of surfactant, compounded halogen-free flame retardant 10 parts, 3 parts of sodium citrate, 8 parts of sulfonated ricinoleol sodium salt, 5 parts of croscarmellose sodium.

[0031] The steps of polyurethane foaming are:

[0032] 1) Weigh the polyether polyol, chain extender, foaming agent, surfactant, compound halogen-free flame retardant, sodium citrate, sulfonated ricinoleol sodium salt, Croscarmellose sodium, stirred at 30-40°C to make a mixed solution;

[0033] 2) Weigh the perlite in the proportion by weight and add it to the mixed solution prepared in step 1), continue to stir, and keep it warm at 40-50°C for 30-50 minutes to prepare polyurethane foam, and put it in a vacuum at 60°C Dried in a desiccator for 40 hours, ready to use;

[0034] 3) The polyurethane foam prepared in step...

Embodiment 2

[0036] The polyurethane mixture includes the following components by weight: 80 parts of polyether polyol, 30 parts of perlite, 16 parts of chain extender, 6 parts of foaming agent, 3 parts of surfactant, compounded halogen-free flame retardant 6 parts, 1 part of sodium citrate, 6 parts of sulfonated ricinoleol sodium salt, 5 parts of croscarmellose sodium.

[0037] The steps of polyurethane foaming are:

[0038] 1) Weigh the polyether polyol, chain extender, foaming agent, surfactant, compound halogen-free flame retardant, sodium citrate, sulfonated ricinoleol sodium salt, Croscarmellose sodium, stirred at 30-40°C to make a mixed solution;

[0039] 2) Weigh the perlite in the proportion by weight and add it to the mixed solution prepared in step 1), continue to stir, and keep it warm at 40-50°C for 30-50 minutes to prepare polyurethane foam, and put it in a vacuum at 60°C Dried in a desiccator for 40 hours, ready to use;

[0040] 3) The polyurethane foam prepared in step 2...

Embodiment 3

[0042] The polyurethane mixture includes the following components by weight: 70 parts of polyether polyol, 30 parts of perlite, 20 parts of chain extender, 7 parts of foaming agent, 3 parts of surfactant, compounded halogen-free flame retardant 8 parts, 2 parts of sodium citrate, 7 parts of sulfonated ricinoleol sodium salt, 5 parts of croscarmellose sodium.

[0043] Further, the polyurethane foaming step in the step 3) is:

[0044] 1) Weigh the polyether polyol, chain extender, foaming agent, surfactant, compound halogen-free flame retardant, sodium citrate, sulfonated ricinoleol sodium salt, Croscarmellose sodium, stirred at 30-40°C to make a mixed solution;

[0045] 2) Weigh the perlite in the proportion by weight and add it to the mixed solution prepared in step 1), continue to stir, and keep it warm at 40-50°C for 30-50 minutes to prepare polyurethane foam, and put it in a vacuum at 60°C Dried in a desiccator for 40 hours, ready to use;

[0046] 3) The polyurethane foa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com