Preparation method of nanofiltration membrane based on polyamidoxime as boundary layer

A polyamidoxime, nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of low permeation flux, increased energy consumption and production cost, and large water molecule transmission resistance. and other problems, to achieve the effect of increasing the number of permeation transmission channels, increasing the effective permeation area, and improving the solute retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a preparation method of a nanofiltration membrane based on polyamidoxime as a boundary layer, comprising the following steps:

[0037] (1) polyamidoxime and alkaline solution are mixed, obtain polyamidoxime alkali solution;

[0038] (2) dipping the support layer in the polyamidoxime alkali solution obtained in the step (1) and drying to obtain the support layer coated by the polyamidoxime;

[0039] (3) dipping the support layer coated with the polyamidoxime obtained in the step (2) in an aqueous solution of piperazine to obtain a support layer impregnated with piperazine;

[0040] (4) dropwise addition of trimesoyl chloride solution on the surface of the piperazine-impregnated support layer obtained in the step (3) to carry out interfacial reaction to obtain a nanofiltration membrane based on polyamidoxime as the boundary layer.

[0041] In the present invention, unless otherwise specified, the raw materials used are conventional commercially ava...

Embodiment 1

[0076] One, the preparation method of polyamidoxime

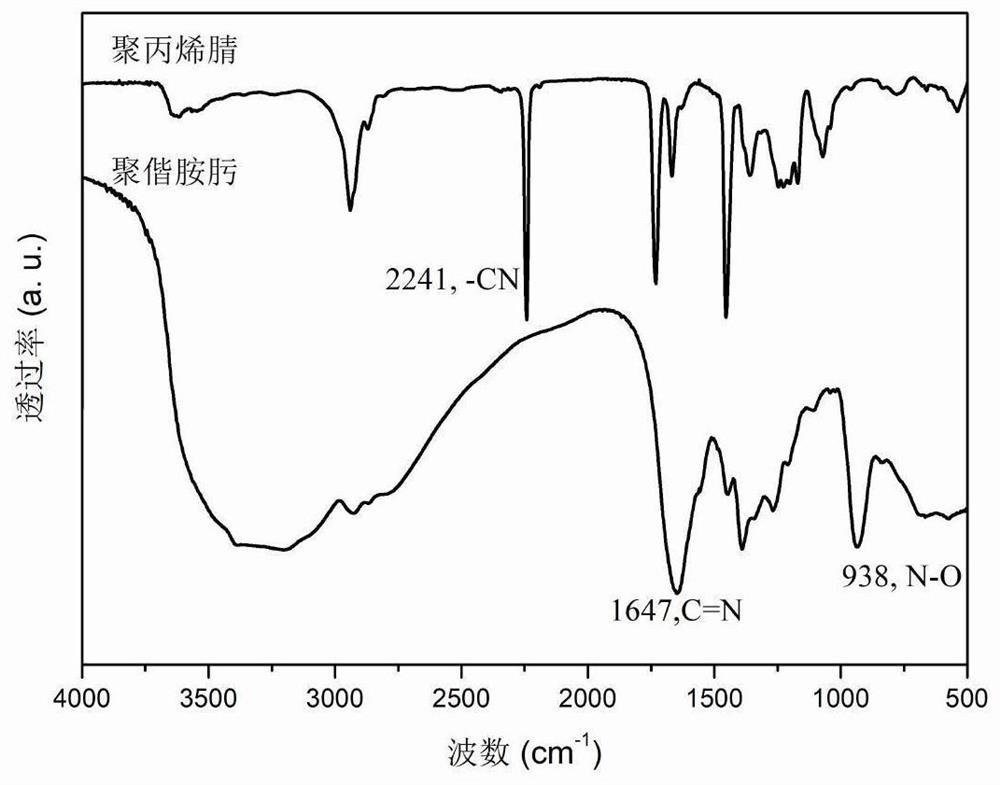

[0077] Add 5.0040g of hydroxylamine hydrochloride to 40mL of N,N-dimethylformamide (mass concentration is 11.6%), add 2.7600g of solid sodium hydroxide after dissolving completely to form a mixed solution, and then dissolve 1.5900g of polyacrylonitrile into the above mixed solution in the hydroxylamination reaction at 80 ° C for 15 hours, then the above-mentioned reaction solution was mixed with 500 mL of pure water to separate out a white solid, which was filtered to obtain a white solid, which was successively washed with water, washed with ethanol and dried to obtain 1.2927 g of polyamide. amidoxime powder;

[0078] Wherein, the material ratio of the hydroxylamine hydrochloride, polyacrylonitrile and basic compound is 2:1:2.

[0079] 2. Preparation method of nanofiltration membrane based on polyamidoxime as boundary layer

[0080] (1) the polyamidoxime prepared by 0.3000g above-mentioned method and the sodium hydroxide...

Embodiment 2

[0088] The nanofiltration membrane NFM-0.5 based on polyamide oxime as the interface layer was prepared according to the method of Example 1, wherein the mass concentration of polyamide oxime in the alkaline solution of polyamide oxime was 0.5 wt%.

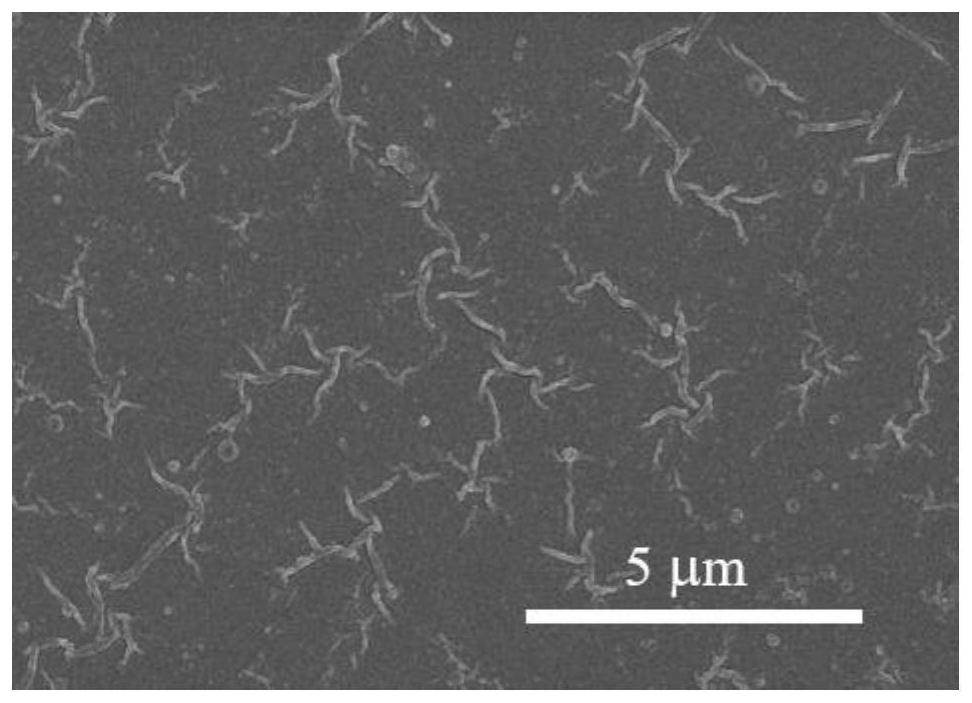

[0089] Figure 4 The scanning electron micrograph of the upper surface of the nanofiltration membrane NFM-0.5 based on polyamidoxime prepared for the boundary layer for embodiment 2, by Figure 4 It can be seen that the number of nanoribbon wrinkled structures on the surface of NFM-0.5 prepared in Example 2 is more than that of NFM-0.3.

[0090] Figure 9 For the PA layer cross-sectional scanning electron micrograph of the nanofiltration membrane NFM-0.5 of the nanofiltration membrane NFM-0.5 that is prepared based on polyamidoxime in embodiment 2, by Figure 9 It can be seen that the thickness of the PA layer of NFM-0.5 prepared in Example 2 is obviously thinner than that of NFM-0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com