Reverse osmosis membrane with PE microporous membrane as base material and preparation method of reverse osmosis membrane

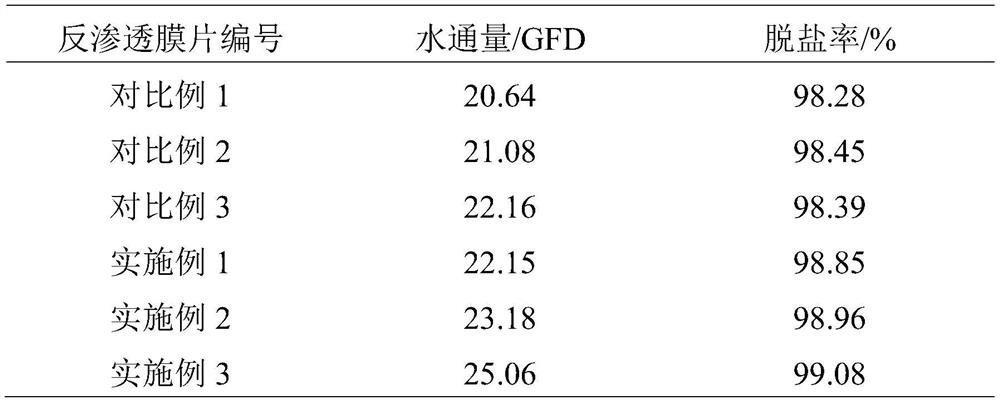

A technology of reverse osmosis membrane and microporous membrane, which is applied in the direction of reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc. Uneven pore size on the surface of the membrane, etc., to achieve excellent water flux and rejection rate, small pore size, and uniform polyamide layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the above-mentioned reverse osmosis membrane with the PE microporous membrane as the substrate, comprising the following steps:

[0035] 1) Coating the polysulfone casting liquid on the surface of the PE microporous membrane, and obtaining the PE microporous membrane covered with the polysulfone layer after curing;

[0036] 2) Add m-phenylenediamine, triethylamine and camphorsulfonic acid into deionized water, and stir magnetically to obtain an aqueous phase solution; add trimesoyl chloride to n-hexane, stir until dissolved, and obtain trimesoyl chloride- n-hexane oil phase solution; immerse the PE microporous membrane covered with polysulfone layer obtained in step 1) into the water phase solution, remove the solvent after taking it out, and then immerse in the prepared trimesoyl chloride-n-hexane oil phase solution Carry out interfacial polymerization reaction to form a polyamide layer, remove the solvent n-he...

Embodiment 1

[0048] The reverse osmosis membrane with PE microporous membrane as the base material includes PE microporous membrane, polysulfone layer coated on the PE microporous membrane and polyamide layer coated on the polysulfone layer; the pore size of the PE microporous membrane is 0.01-10μm, porosity 70-95%, thickness 20-120μm;

[0049] PE microporous membrane includes high-density PE, chain extender, hydrophilic polymer and inorganic particles; the mass ratio of high-density PE, chain extender, hydrophilic polymer and inorganic particles is 2:1:2:1. The hydrophilic polymer is polyacrylic acid; the inorganic particles are titanium dioxide; the chain extender is phthalic anhydride;

[0050] Above-mentioned PE microporous membrane is the preparation method of the reverse osmosis membrane of substrate, comprises the following steps:

[0051] 1) Mix high-density PE, chain extender, hydrophilic polymer and inorganic particles with a mass ratio of 2:1:2:1 and pour them into a screw extrud...

Embodiment 2

[0056] The reverse osmosis membrane with PE microporous membrane as the base material includes PE microporous membrane, polysulfone layer coated on the PE microporous membrane and polyamide layer coated on the polysulfone layer; the pore size of the PE microporous membrane is 0.01-10μm, porosity 70-95%, thickness 20-120μm;

[0057] PE microporous membrane includes high-density PE, chain extender, hydrophilic polymer and inorganic particles; the mass ratio of high-density PE, chain extender, hydrophilic polymer and inorganic particles is 2:1:2:1. The hydrophilic polymer is polyacrylic acid; the inorganic particles are titanium dioxide; the chain extender is phthalic anhydride;

[0058] Above-mentioned PE microporous membrane is the preparation method of the reverse osmosis membrane of substrate, comprises the following steps:

[0059] 1) Mix high-density PE, chain extender, hydrophilic polymer and inorganic particles with a mass ratio of 2:1:2:1 and pour them into a screw extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com