Preparation method of high-flux antifouling composite filter membrane

A high-flux, composite membrane technology, applied in chemical instruments and methods, membranes, membrane technology, etc., to achieve environmental friendliness, good anti-fouling effect, good high permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

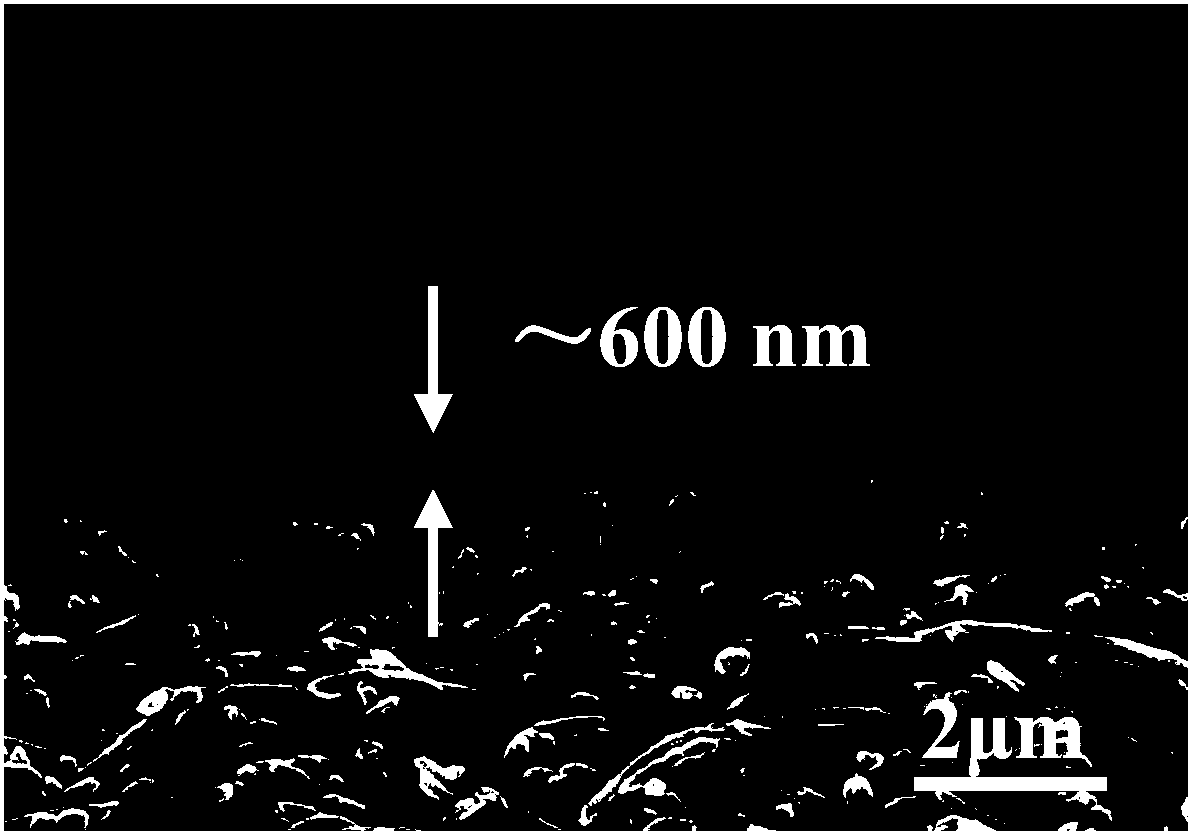

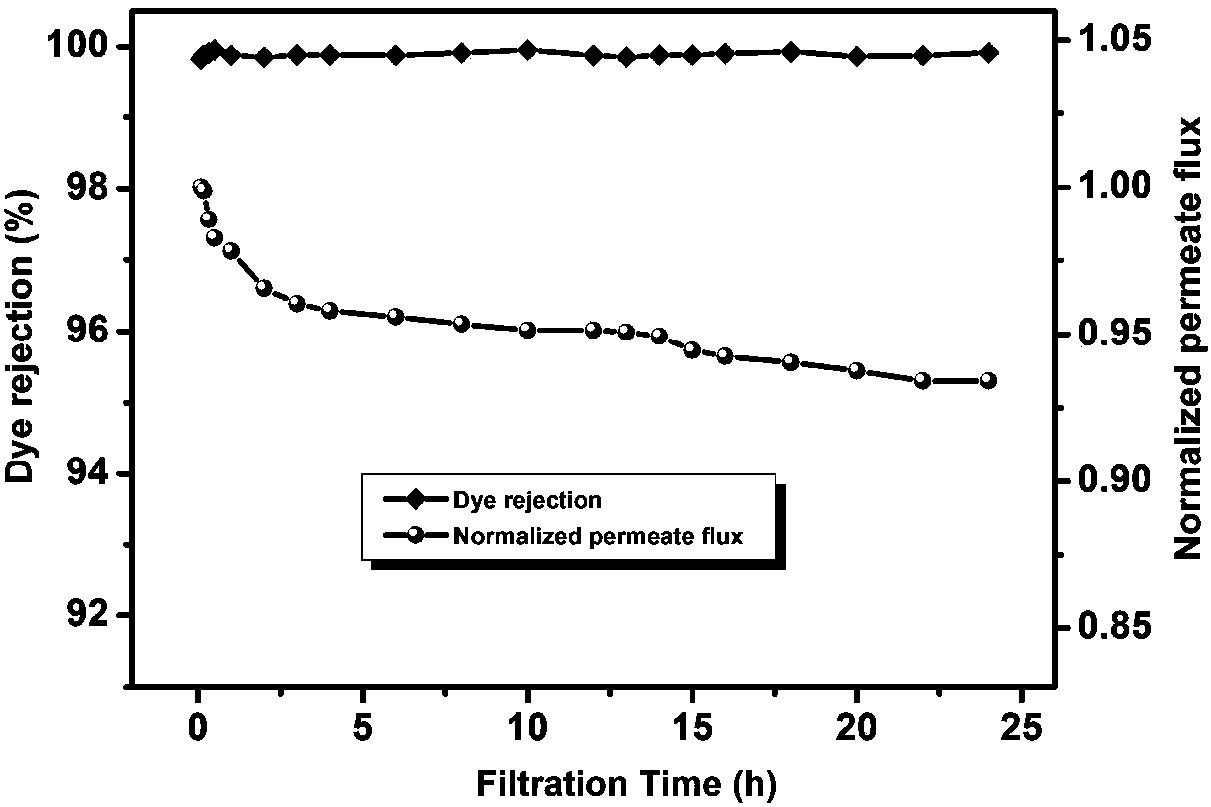

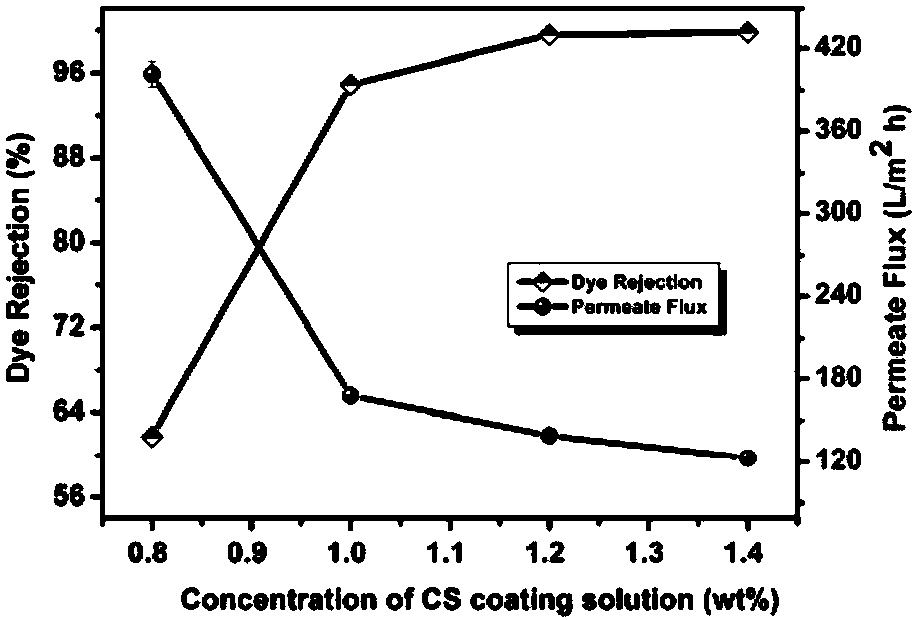

[0025] A kind of preparation method of high flux antifouling chitosan / polyacrylonitrile nanofiber matrix composite filter membrane comprises: 1, polyacrylonitrile 8g is dissolved in N, in N-dimethylformamide (DMF) solvent 92g, obtains Transparent and uniform electrospinning solution; the manufacturer of polyacrylonitrile is Jinshan Petrochemical, and the molar mass fraction is M w =120000g / mol; 2, dissolving chitosan in 1% acetic acid aqueous solution to prepare a coating solution with a mass fraction of 1.2%; 3, adding the electrospinning solution in step 1 to the syringe, The extrusion is controlled by a micro-injection pump, the nozzle of the syringe is connected to the high-voltage positive electrode, the electrospinning parameters are controlled at a voltage of 22kv, the nozzle aperture is 0.7mm, the solution flow rate is 18μl / min, the ambient temperature is 35°C, and the relative air humidity is 35%. Electrospinning is carried out , to obtain nanofibers, the average diam...

Embodiment 2

[0028] A high-throughput antifouling sodium alginate / polyethersulfone nanofiber-based composite membrane preparation method comprises: 1. Dissolving 26 g of polyethersulfone in N, N-dimethylformamide (DMF) solvent 74 g to obtain Transparent and uniform electrospinning solution; polyethersulfone is produced by Solvay (Shanghai) Co., Ltd., and the molar mass fraction is M w =64000g / mol; 2. Sodium alginate was dissolved in deionized water to prepare a coating solution with a mass fraction of 2%; 3. The electrospinning solution in step 1 was added to the syringe, and injected by microinjection The pump controls the extrusion, the nozzle of the syringe is connected to the high-voltage positive electrode, the electrospinning parameters are controlled at a voltage of 24kv, the nozzle aperture is 0.7mm, the solution flow rate is 16μl / min, the ambient temperature is 30°C, and the relative air humidity is 30%. Electrospinning is performed to obtain nano fiber, the average diameter of th...

Embodiment 3

[0031] A kind of preparation method of high-throughput antifouling sodium polyacrylate / polyvinylidene fluoride nanofiber matrix composite filter membrane comprises: 1, polyvinylidene fluoride 16g is dissolved in 84g N, N-dimethylformamide (DMF) / acetone In a mixed solvent with a mass ratio of 7:3, a transparent and uniform electrospinning solution is obtained; the supplier of polyvinylidene fluoride is Aldrich, and the molar mass fraction is M w=370000g / mol; 2. Sodium polyacrylate was dissolved in deionized water to prepare a coating solution with a mass fraction of 2.5%; 3. The electrospinning solution in step 1 was added to the syringe, and the extrusion was controlled by a micro-injection pump out, the nozzle of the syringe is connected to the high-voltage positive electrode, the electrospinning parameters are controlled at a voltage of 18kv, the nozzle aperture is 0.3mm, the solution flow rate is 40μl / min, the ambient temperature is 50°C, and the relative air humidity is 30%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com