Multi-stage flow-dividing first sheet for brazing heat exchanger sheet group

A technology of heat exchangers and plate groups, applied in the direction of heat exchanger types, indirect heat exchangers, fixed plate conduit components, etc., can solve the problems of heat exchanger performance degradation, instability, and poor uniformity of medium circulation, etc., to achieve Improve heat transfer formation, ensure heat transfer stability, and improve heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in further detail now in conjunction with embodiment.

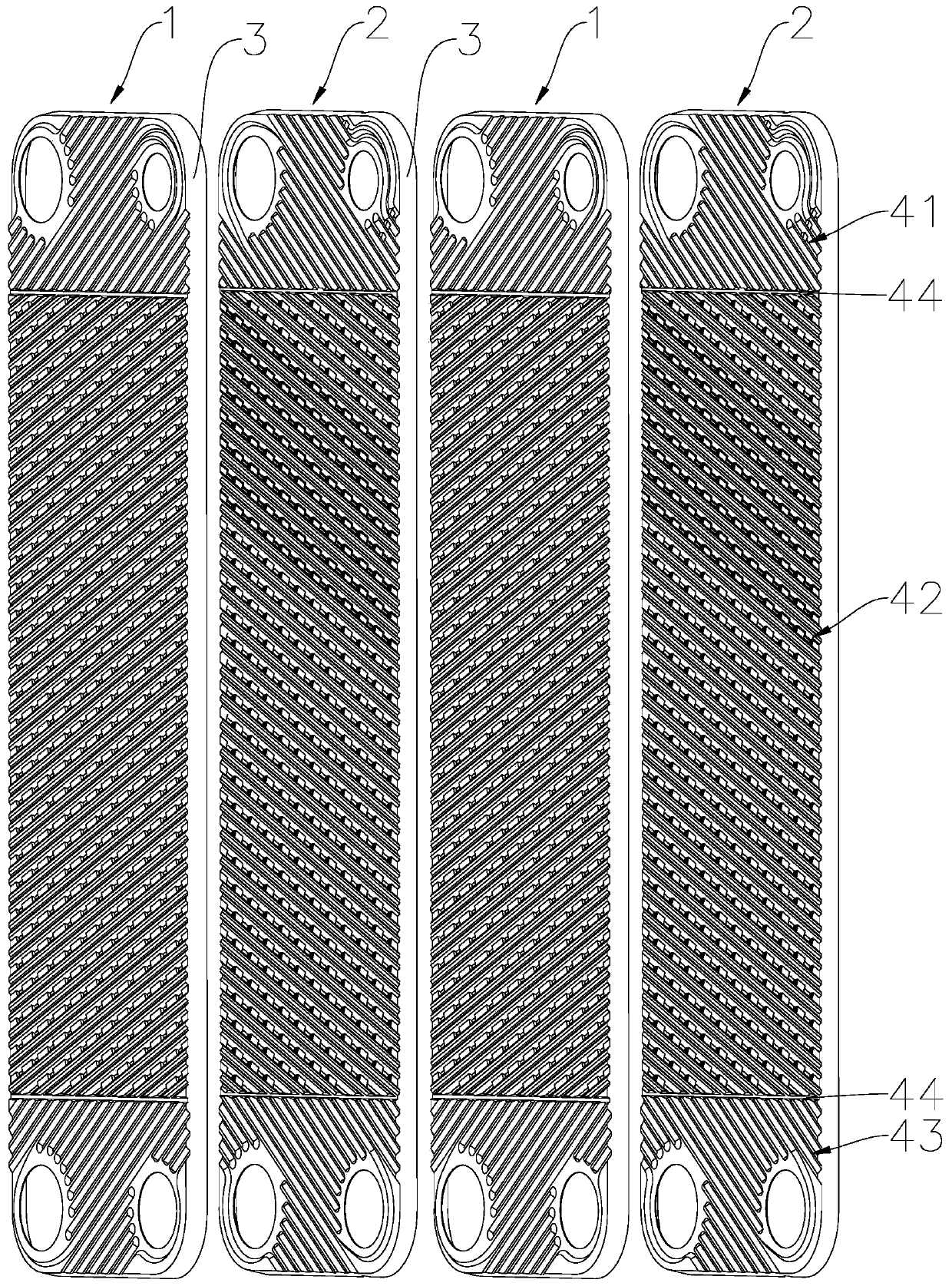

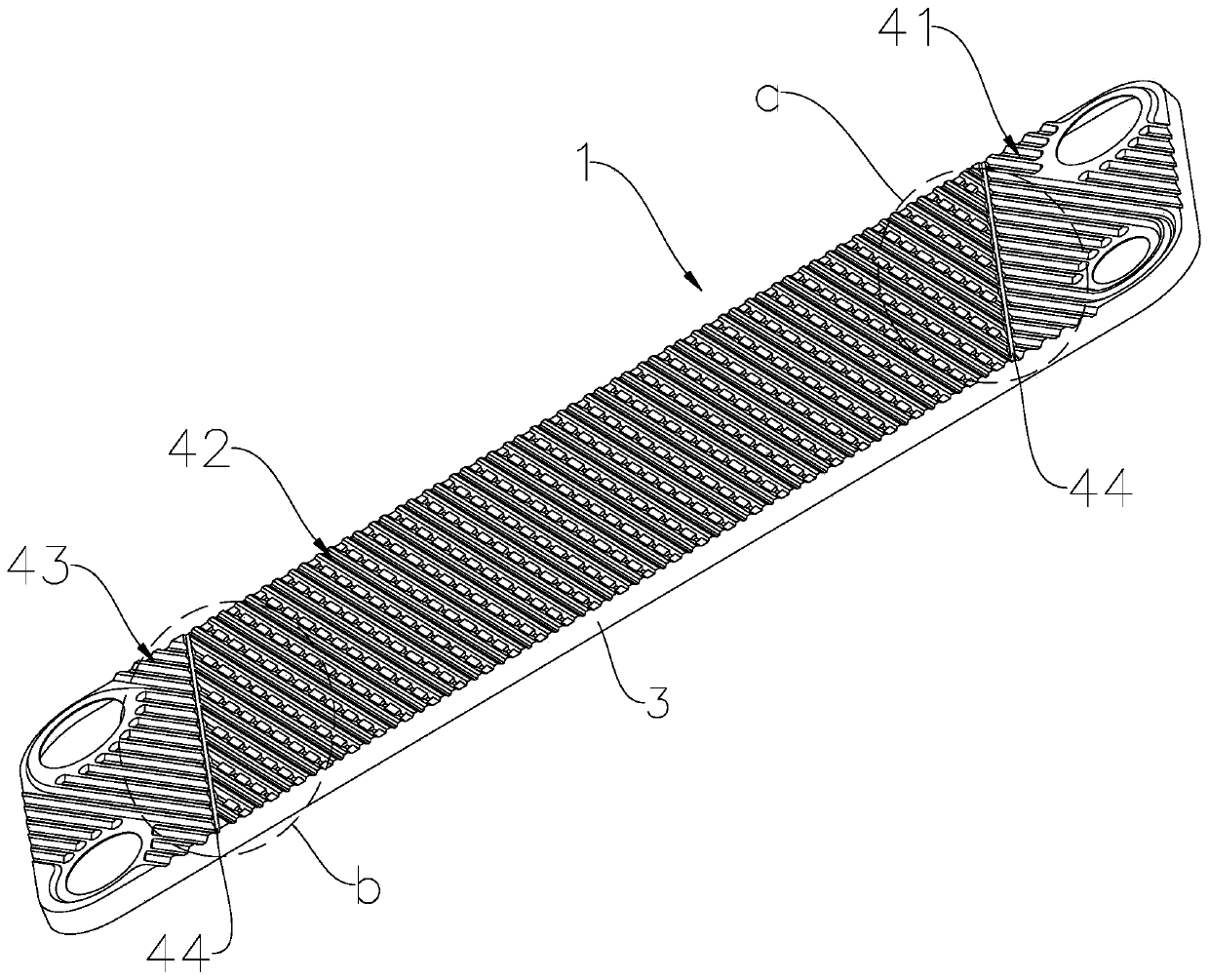

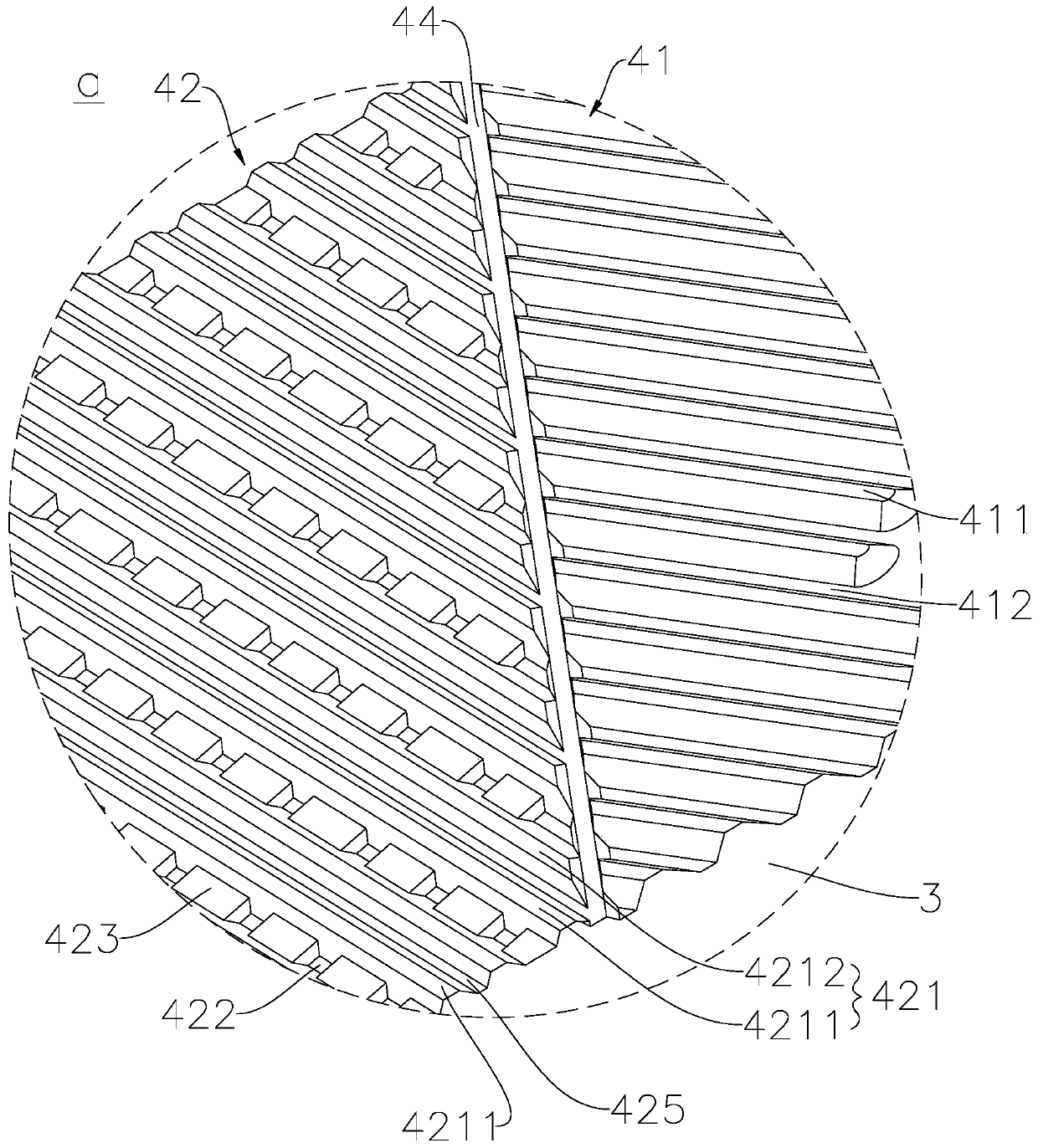

[0041] A kind of multi-stage shunt brazed heat exchanger plate group uses the first plate, such as figure 2 As shown, the first sheet includes the main panel and the surrounding baffles 3, the main panel includes the flow distribution area 41, the main heat exchange area 42 and the confluence area 43, the gap between the flow distribution area 41 and the main heat exchange area 42 and the main heat exchange area 42 and the confluence area 43 are provided with splitter ribs 44 for evenly distributing the medium flowing from the diversion area 41 into the main heat exchange area 42 and the medium flowing from the main heat exchange area 42 into the confluence area 43 . The setting of the distribution ribs 44 can make the medium flowing from the distribution area 41 to the main heat exchange area 42 be evenly distributed at the distribution ribs 44, which is conducive to the uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com