Method for preparing binary copolymer

A technology of binary copolymers and polymers, which is applied in the field of preparation of binary copolymers to achieve good anti-fouling effect and excellent anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The amount of the fixed initiator is 0.5% of the mass of the monomer, the molar ratio of the new monomer to acrylamide is 6:4, the mass ratio of water to the monomer is 2:1, pH=7.0, and the copolymerization is obtained when the temperature of the polymerization system is changed. Table 1 shows the relationship between the reaction temperature and the anti-fouling rate.

[0019] Table 1: Reaction temperature and copolymer antifouling rate

[0020]

[0021] It can be seen from Table 1 that as the temperature increases, the anti-fouling rate increases gradually. When the temperature rises to 75°C, the anti-fouling rate reaches the maximum value, and then continues to rise, and the anti-fouling rate decreases slightly. This is because the initiator used is ammonium persulfate, and its decomposition temperature is around 70°C. If the polymerization temperature is too low, the decomposition rate of the initiator is slow, and there are few free radicals, and the induction p...

Embodiment 2

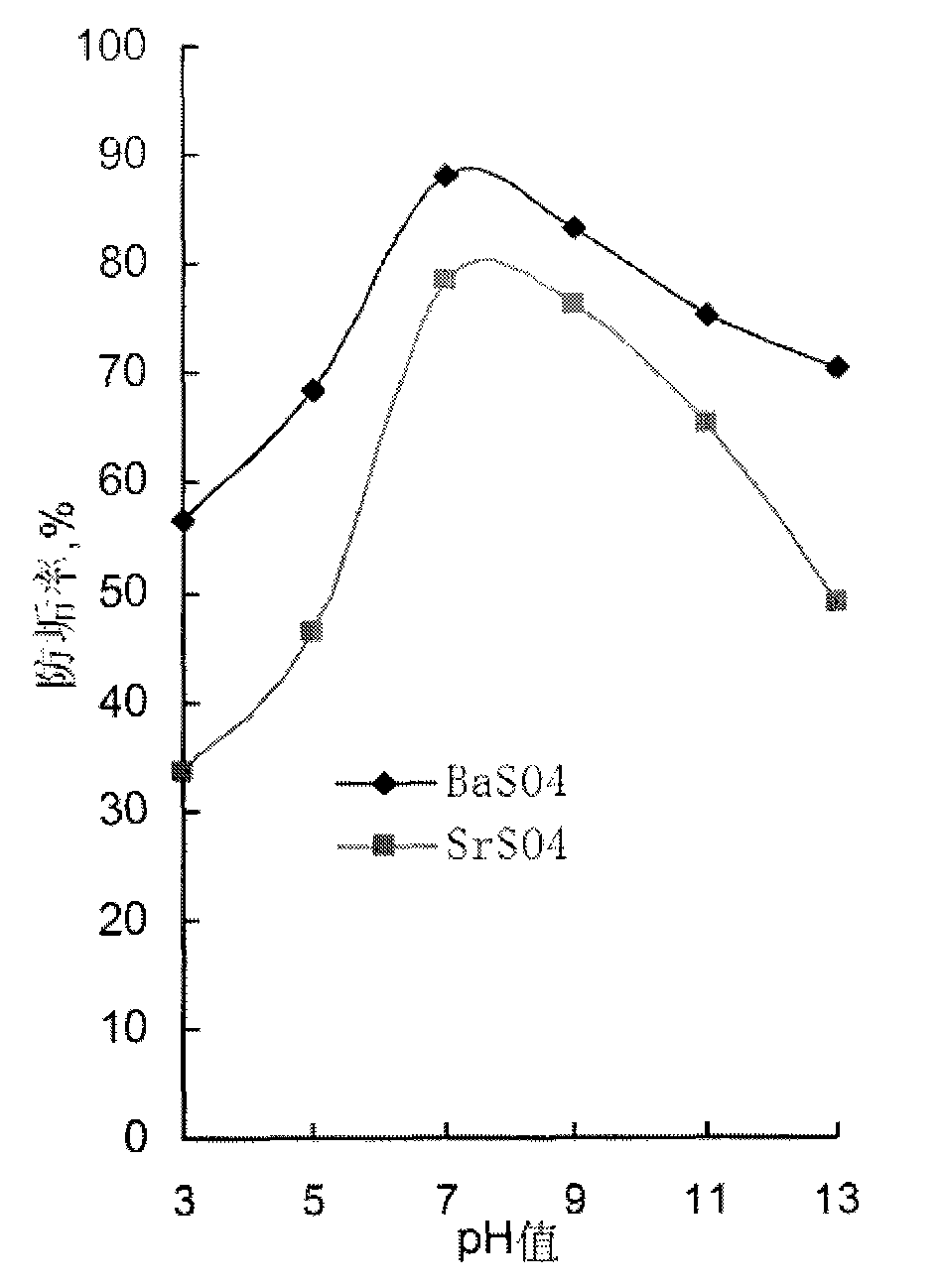

[0023] Fix the molar ratio of the new monomer to acrylamide at 6:4, the amount of the initiator is 0.5% of the mass of the monomer, react at a constant temperature of 75°C for 5 hours in a polymerization system with different pH values to obtain a polymer antifouling agent, and the pH value of the polymerization system is Influence of anti-fouling effect, the results are shown in figure 1 . Depend on figure 1 It can be seen that as the pH value of the polymerization system increases, the anti-fouling rate increases. When the pH value is 7.0, the anti-fouling rate reaches the maximum, and then increases the pH value, and the anti-fouling rate decreases gradually. Therefore, the pH of the polymerization system was set at pH=7.0.

Embodiment 3

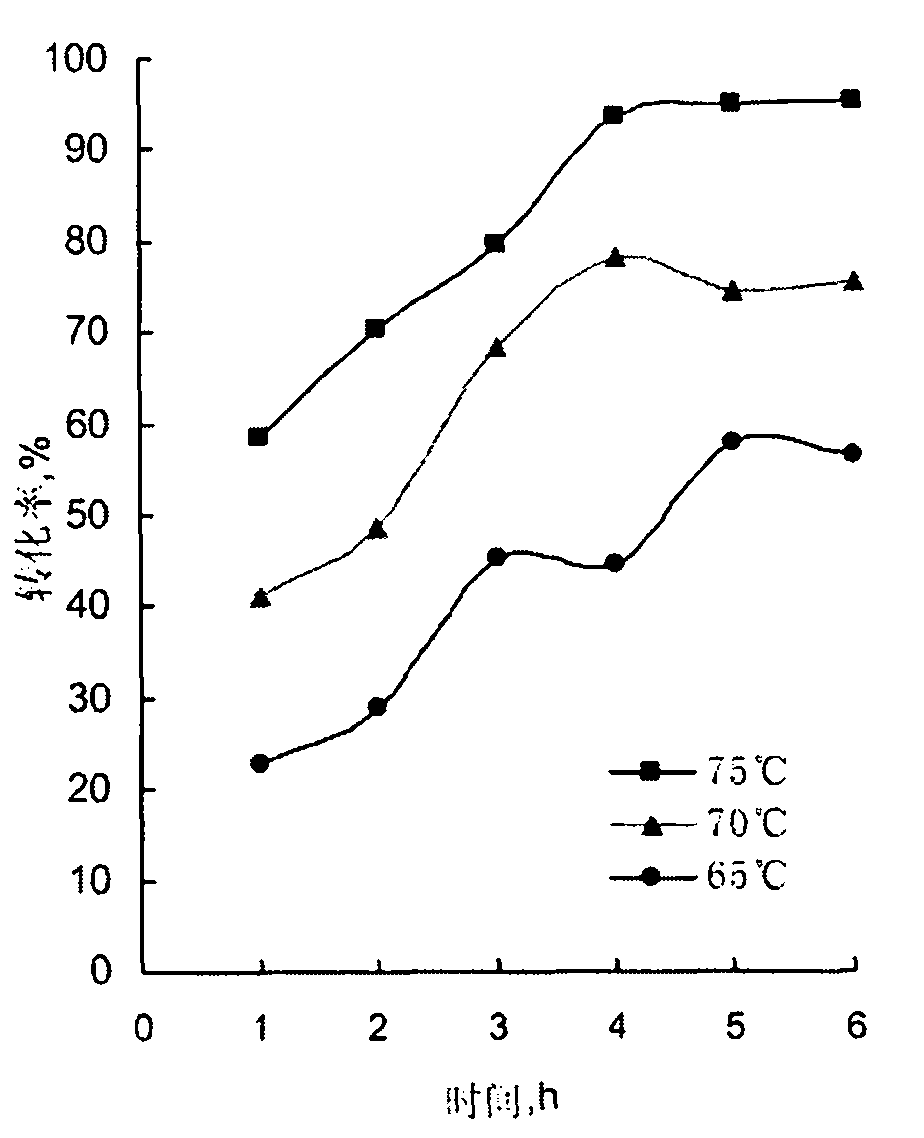

[0025] The molar ratio of new monomer and acrylamide is fixed at 6:4, the amount of initiator is 0.5% of the monomer mass, pH=7.0, and the reaction time and temperature are changed to prepare the copolymer antifouling agent. The influence of reaction time on conversion rate , see the result figure 2 . from figure 2 It can be seen that with the increase of the reaction time, the conversion rate of the monomer in the polymerization reaction is gradually increasing at different temperatures, and when the reaction time reaches 5h, the conversion rate remains basically unchanged; at the same time, as the reaction temperature increases, The conversion rate also gradually increased. Therefore, the polymerization reaction time was set as 5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com