Porous polyurethane film used for artificial skin and having gradient porous structure and preparation method of porous polyurethane

A polyurethane film and gradient hole technology, applied in medical science, prostheses, etc., can solve the problems that it is difficult to resist the invasion of external bacteria, the pore size of the upper layer of silicone rubber is too large, and it cannot be used for a long time, so as to keep the wound moist, excellent mechanical properties, The effect of good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

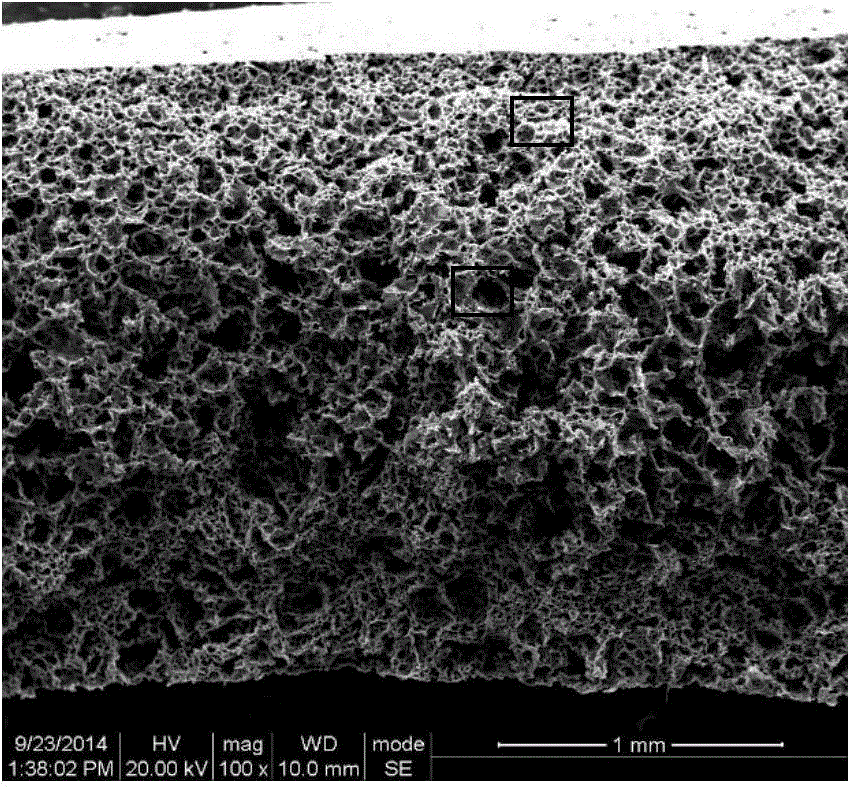

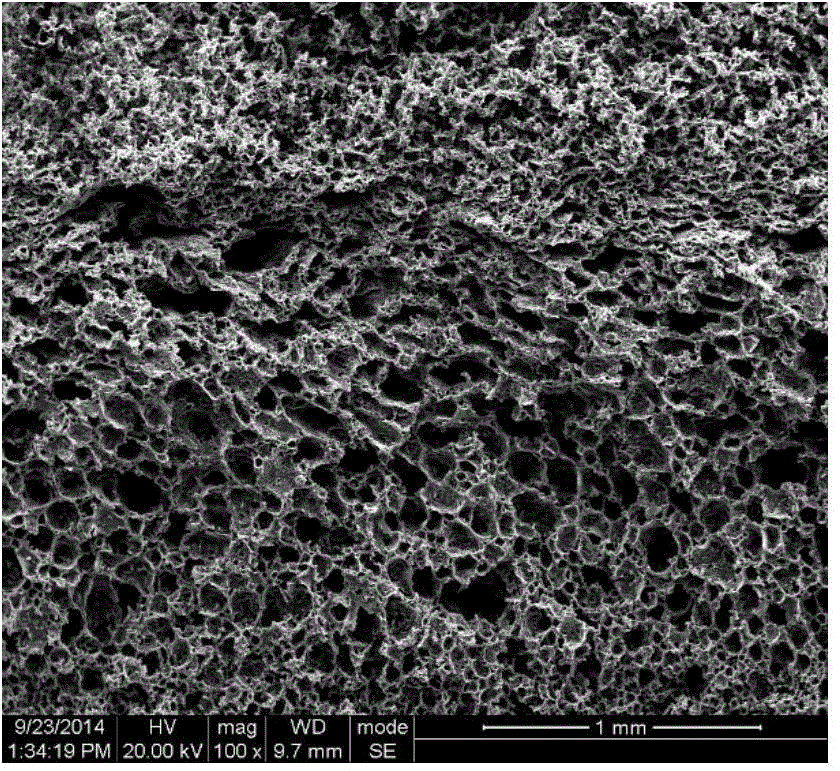

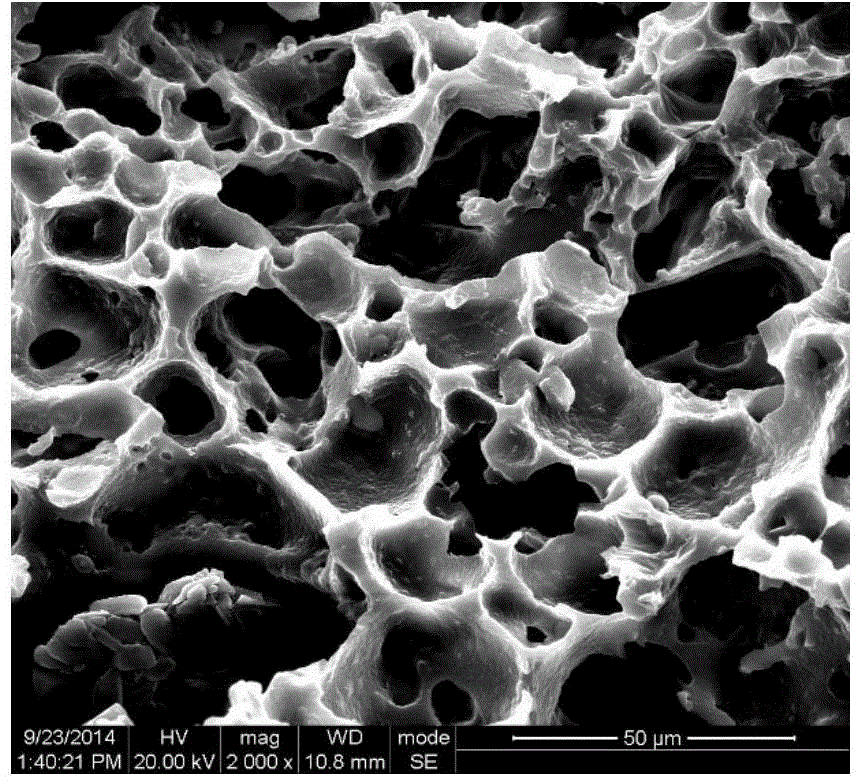

[0052] Dissolve four parts of 25g of medical-grade polyurethane in 200mL of N,N-dimethylformamide at 60°C, then add 60g, 80g, 100g, and 120g of sodium citrate with a particle size of 75-150μm, and stir mechanically After 1 hour, defoam for 20 minutes at room temperature under a vacuum of 0.06 MPa. The defoamed suspension was evenly poured into a polytetrafluoroethylene mold with a film thickness of 2mm, and then placed in absolute ethanol at 25°C for phase separation and solidified to form a film. The cured polyurethane porous membrane was soaked in deionized water at 25°C for 72 hours to fully filter out the porogen, and the water was changed every 24 hours. The polyurethane porous membrane from which the porogen was removed was dried in a blast oven at 40° C. to obtain a porous polyurethane membrane with a gradient pore structure.

Embodiment 2

[0054] Dissolve 25g of medical-grade polyurethane in 200mL of N,N-dimethylformamide at 60°C, then add 80g of sodium citrate with a particle size of 75-150μm, stir mechanically for 1 hour, and then dissolve it at room temperature under a vacuum of 0.06 Degassing at MPa for 20min. The defoamed suspension was evenly poured into the polytetrafluoroethylene mold for three times, and the film thickness was 1mm each time. After the film was coated, it was put into 25°C absolute ethanol for phase separation, and solidified to form a film. The polyurethane porous membrane cured for the third time was soaked in deionized water at 25°C for 72 hours to fully filter out the porogen, and the water was changed every 24 hours. The polyurethane porous membrane from which the porogen was removed was dried in a blast oven at 40° C. to obtain a porous polyurethane membrane with a gradient pore structure.

Embodiment 3

[0056] Dissolve 10g of medical-grade polyurethane in 200mL of N,N-dimethylformamide at 20°C, then add 10g of sodium citrate with a particle size of 20-75μm, stir mechanically for 1h, and then dissolve it at room temperature under a vacuum of 0.06 Degassing at MPa for 10 minutes. Pour the defoamed suspension evenly into a glass mold with a coating film thickness of 1mm, then put it in absolute ethanol at 20°C for phase separation, and solidify to form a film. The cured polyurethane porous membrane was soaked in deionized water at 5°C for 72 hours to fully filter out the porogen, and the water was changed every 24 hours. The polyurethane porous membrane from which the porogen was removed was dried in a blast oven at 40° C. to obtain a porous polyurethane membrane with a gradient pore structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com