Preparation method of multi-hole metal tube surface zirconia intermediate layer

A porous metal and transition layer technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve problems such as uniform plating on the surface of porous metal tubes, reduction of gas permeability of porous metal supports, complicated processes, etc. problems, to achieve the effect of preventing element diffusion, reasonable design, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the zirconia transition layer on the surface of the porous metal tube of the present embodiment comprises the following steps:

[0024] Step 1, mixing zirconium powder with a Fischer average particle size of 1.5 μm and deionized water, stirring evenly, and preparing a suspension 2; the solid content of the suspension 2 is 15%;

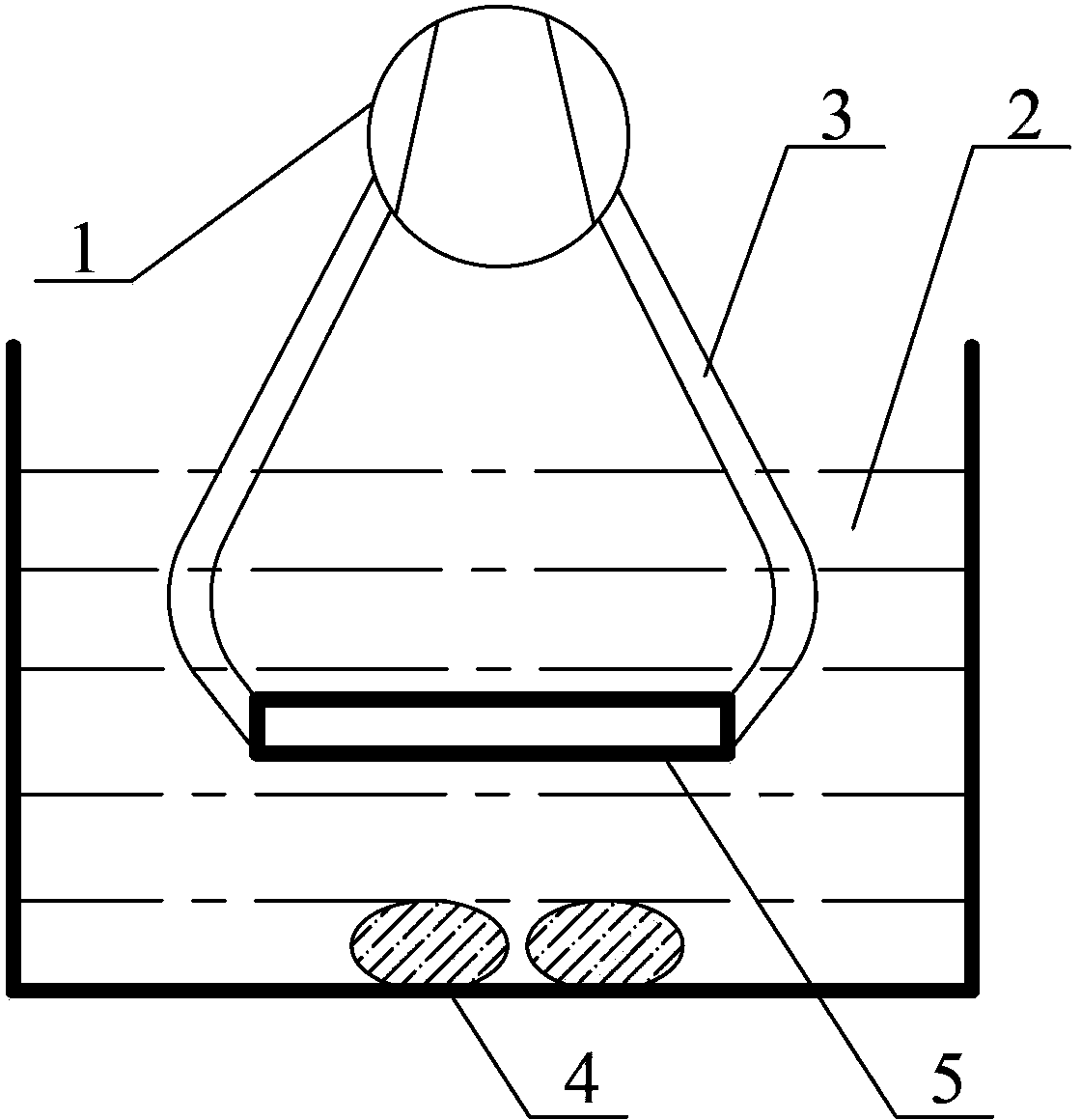

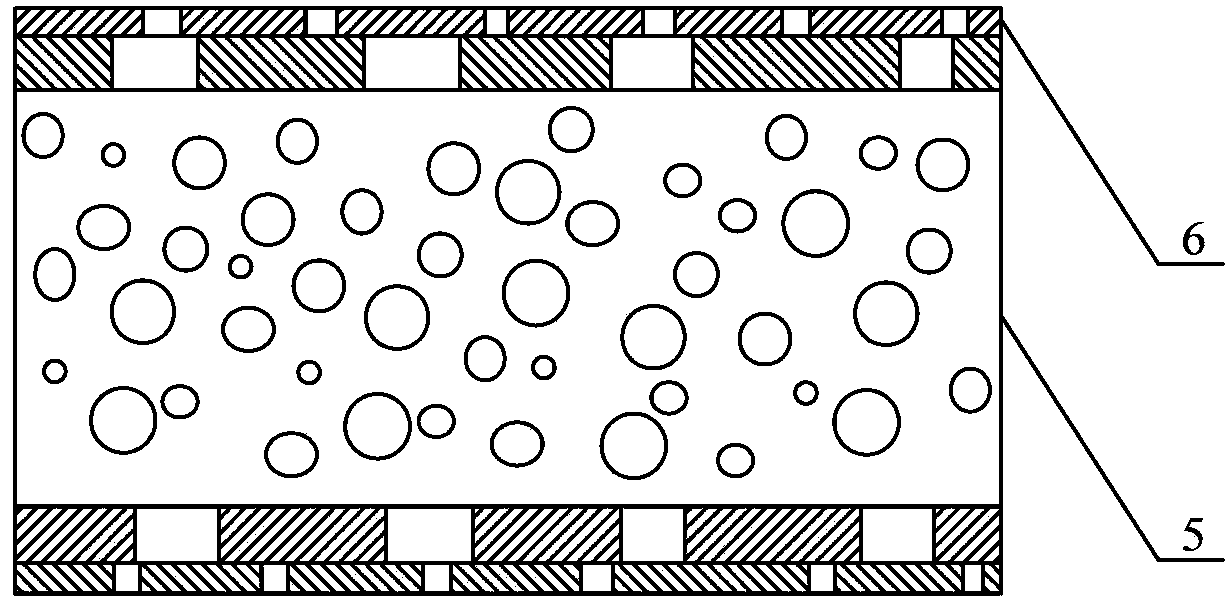

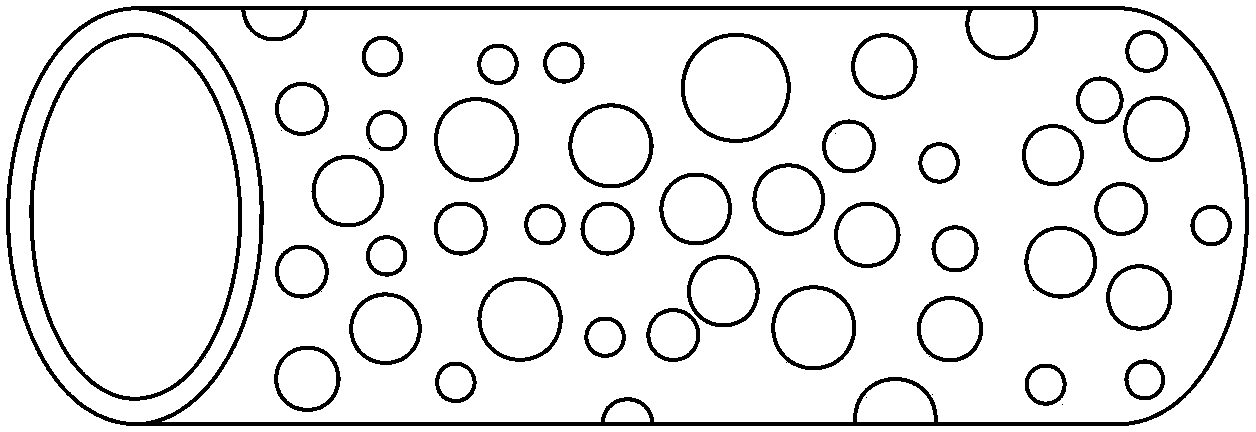

[0025] Step 2: Connect the two ends of the porous metal tube 5 with an outer diameter of 6 mm to the circulating water vacuum pump 1 with a polytetrafluoroethylene hose 3, and then immerse the porous metal tube 5 into the suspension 2 in step 1 , turn on the circulating water vacuum pump 1 for negative pressure suction for 3 minutes, the zirconium powder in the suspension 2 in step 1 is trapped on the outer surface of the porous metal tube 5, thereby forming a zirconium film on the outer surface of the porous metal tube 5, and then The porous metal tube 5 formed with a zirconium film on the outer surface is dried at roo...

Embodiment 2

[0029] The preparation method of the zirconia transition layer on the surface of the porous metal tube of the present embodiment comprises the following steps:

[0030] Step 1, mixing zirconium powder with an average Fischer particle size of 1.1 μm and absolute ethanol, stirring evenly, and preparing a suspension 2; the solid content of the suspension 2 is 12%;

[0031] Step 2. Connect the two ends of the porous metal tube 5 with an outer diameter of 4 mm to the circulating water vacuum pump 1 with a polyvinyl chloride hose 3, and then immerse the porous metal tube 5 into the suspension 2 in step 1. Turn on the circulating water vacuum pump 1 for negative pressure suction for 3 minutes, and the zirconium powder in the suspension 2 described in step 1 is trapped on the outer surface of the porous metal tube 5, thereby forming a zirconium film on the outer surface of the porous metal tube 5, and then The porous metal tube 5 with a zirconium film formed on the outer surface is dr...

Embodiment 3

[0035] The preparation method of the zirconia transition layer on the surface of the porous metal tube of the present embodiment comprises the following steps:

[0036] Step 1, mixing zirconium powder with a Fischer particle size of 0.8 μm and deionized water, stirring evenly, and preparing a suspension 2; the solid content of the suspension 2 is 5%;

[0037] Step 2: Connect the two ends of the porous metal tube 5 with an outer diameter of 8 mm to the circulating water vacuum pump 1 with a polypropylene hose 3, then immerse the porous metal tube 5 into the suspension 2 in step 1, and turn on the Circulating water vacuum pump 1 negative pressure suction 5min, the zirconium powder in the suspension 2 described in step 1 is trapped on the outer surface of the porous metal tube 5, thereby forms a zirconium film on the outer surface of the porous metal tube 5, then the outer surface The porous metal tube 5 with a zirconium film formed on the surface is dried at room temperature; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com