Composite diaphragm and application thereof

A composite diaphragm and diaphragm technology, applied in electrical components, electrochemical generators, batteries, etc., can solve the problems of ceramic electrolytes having no advantage in electrical conductivity, poor ion conductivity, and affecting the wettability of electrolytes, so as to improve power Chemical properties, improving ionic conductivity, and improving heat shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

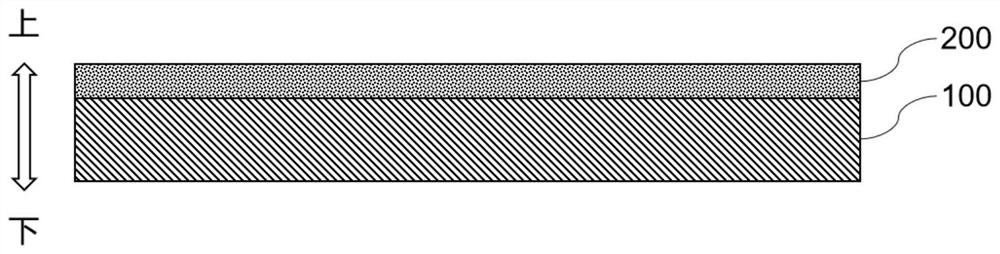

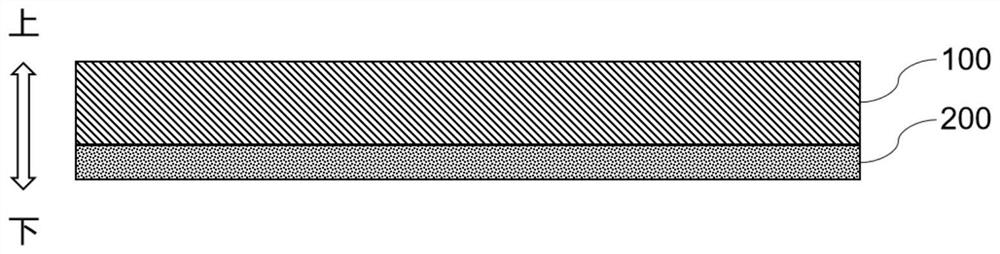

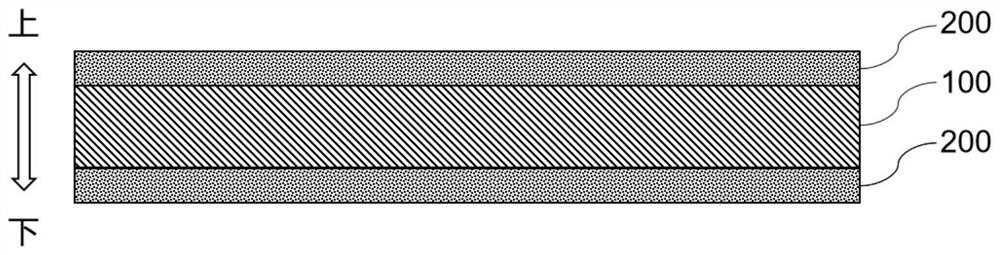

[0046] A composite separator that supports a cathode active lithium source and a ceramic electrolyte. A composite active lithium source and ceramic electrolyte coating is coated on a commercial PP porous separator. The mass composition of the coating material is 35% LATP+60% Li 2 CO 3 +4%NiO+1%PVDF, in which LATP particle size distribution range is 200-600nm, Li 2 CO 3 The particle size distribution range is 20-50nm, and the NiO particle size distribution range is 10-30nm. The coating method is not limited, and the micro-gravure coating process is typically used. After the composite diaphragm is fully baked, the coating thickness is ~3 μm, and the porosity of the diaphragm is 37% as measured by mercury intrusion porosimetry. The heat shrinkage test of the separator was carried out at 130 degrees Celsius, and the measured heat shrinkage rate was 0.8%. Use this diaphragm to assemble a button battery. The battery is composed of positive shell | stainless steel gasket | carbon-...

Embodiment 2

[0048] A composite diaphragm for loading cathode active lithium source and ceramic electrolyte, coating the composite active lithium source and ceramic electrolyte coating on the commercial PP porous diaphragm, the mass composition of the coating material is 40% LLTO+55% Li 2 C 2 o 4 +4%Co 3 o 4 +1%PVDF, in which LLTO particle size distribution ranges from 300 to 500nm, Li 2 C 2 o 4 The particle size distribution range is 20-50nm, Co 3 o 4 The particle size distribution range is 10-20nm, and the coating method is the same as in Example 1. After the composite diaphragm is fully baked, the thickness of the coating is ~2 μm, and the porosity of the diaphragm is 36% as measured by mercury intrusion porosimetry. The heat shrinkage test of the separator was carried out at 130 degrees Celsius, and the measured heat shrinkage rate was 0.9%. Use this diaphragm to assemble a button battery. The battery is composed of positive shell | stainless steel gasket | carbon-coated alumi...

Embodiment 3

[0053] The composite separator described in Example 1 is used as the separator, NCM811 is used as the positive electrode (specific capacity 190mAh / g), graphite / SiO mixture is used as the negative electrode (specific capacity 450mAh / g), and the N / P design value is 1.1, assembled into a pouch battery . After the battery cell is assembled, it is formed under the conditions of 300kgf and 45 degrees Celsius. The current condition of the formation is 0.05C, after charging for 30 minutes, then turn to 0.1C and charge for 2hrs; to 2.8V. The first charge capacity is 7.27Ah, the first discharge capacity is 5.95Ah, the first Coulombic efficiency is 81.8%; the reversible discharge capacity at 1C is 5.69Ah.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com