Graphene regenerated rubber and plastic foamed colloidal particle for soles and preparation method thereof

A technology of regenerated rubber, plastic and graphene, which is applied in the field of rubber and plastic foam products, can solve the problems of affecting the performance of graphene and destroying the crystal structure of graphene, so as to enhance the thermal shrinkage resistance and strength, disperse the impact of damage, shorten the Effect of vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

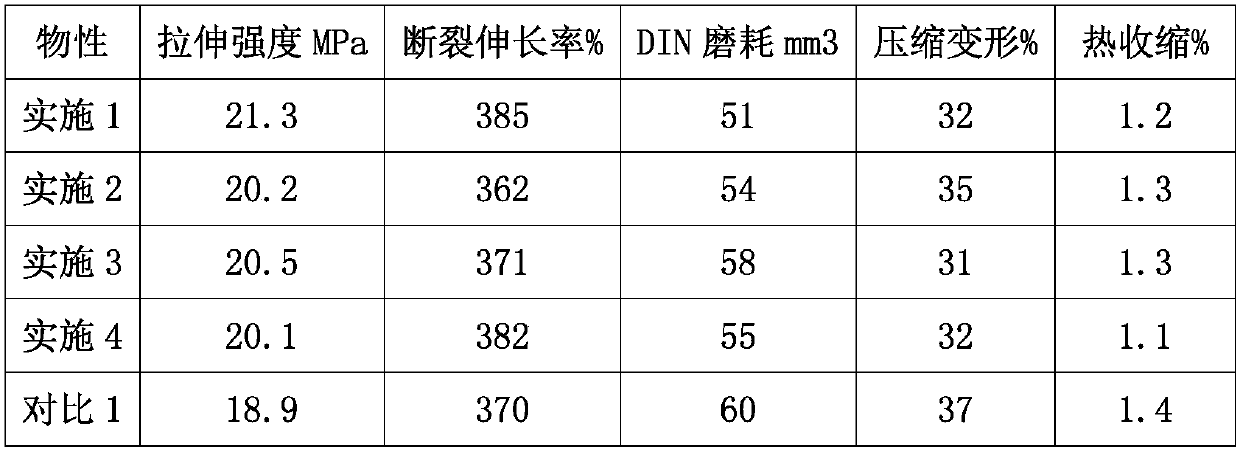

Examples

Embodiment 1

[0021] The present embodiment provides a kind of graphene regenerated rubber and plastic foamed rubber particles for shoe soles, which is composed of the following components in parts by weight: 60 parts of EVA waste; 23 parts of natural rubber; 5 parts of POE elastomer; laminated functionalized graphene 1 part; 0.1 part of poly-N-vinylacetamide; 2.0 parts of white mineral oil; 1.0 part of silicone oil; 1.4 parts of active zinc oxide; 0.8 part of zinc stearate; 0.9 part of stearic acid; 0.9 part of crosslinking agent; 2.5 parts of paraffin; 1.5 parts of azodicarbonamide. Wherein, the crosslinking agent is prepared from insoluble sulfur and dicumyl peroxide in a mass ratio of 2:1.

Embodiment 2

[0023] The present embodiment provides a kind of graphene regenerated rubber and plastic foaming rubber particle for shoe sole, is made up of the component of following parts by weight: EVA waste material 65 parts; Natural rubber 23 parts; POE elastomer 4 parts; Laminated functionalized graphene 2 parts; 0.2 parts of poly-N-vinylacetamide; 2.3 parts of white mineral oil; 1.0 parts of silicone oil; 1.5 parts of active zinc oxide; 0.8 parts of zinc stearate; 1.0 parts of stearic acid; 1.0 parts of crosslinking agent; 3.0 parts of paraffin; 1.8 parts of azodicarbonamide. The crosslinking agent is prepared from insoluble sulfur and dicumyl peroxide in a mass ratio of 2:1.

Embodiment 3

[0025] The present embodiment provides a kind of graphene regenerated rubber and plastic foam rubber particles for shoe soles, which is composed of the following components in parts by weight: 62 parts of EVA waste; 25 parts of natural rubber; 6 parts of POE elastomer; laminated functionalized graphene 1.5 parts; 0.15 parts of poly-N-vinylacetamide; 2.0 parts of white mineral oil; 1.2 parts of silicone oil; 1.4 parts of active zinc oxide; 1.0 parts of zinc stearate; 0.8 parts of stearic acid; 1.0 parts of crosslinking agent; 2.0 parts of paraffin; 1.6 parts of azodicarbonamide. The crosslinking agent is prepared from insoluble sulfur and dicumyl peroxide in a mass ratio of 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com