Novel polyimide microsphere slurry and coated diaphragm thereof

A technology of polyimide microspheres and polyimide, which is applied in the direction of structural parts, electrical components, battery pack parts, etc., can solve the problems of production efficiency decline, and achieve not easy to drop powder, good heat shrinkage resistance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A pure polyimide microsphere-coated polyolefin diaphragm is formed by coating polyimide microspheres on the surface of a wet-process PE diaphragm by using a micro-recess coating process. The preparation method of the above-mentioned polyimide microsphere-coated PE diaphragm comprises the following steps:

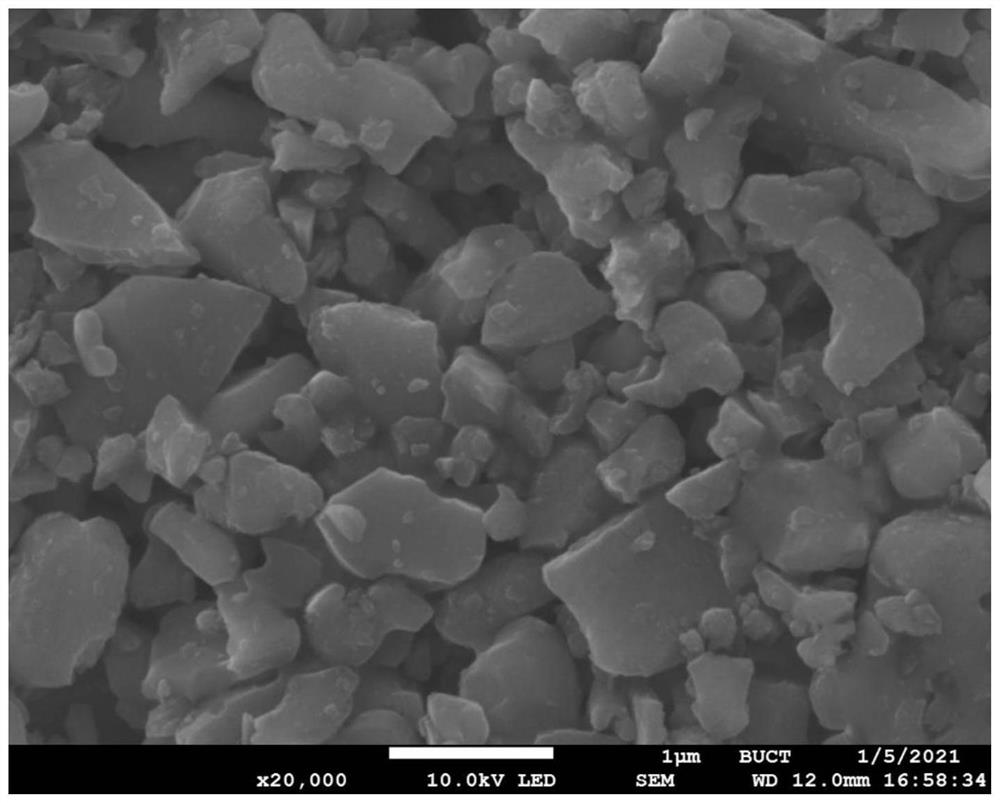

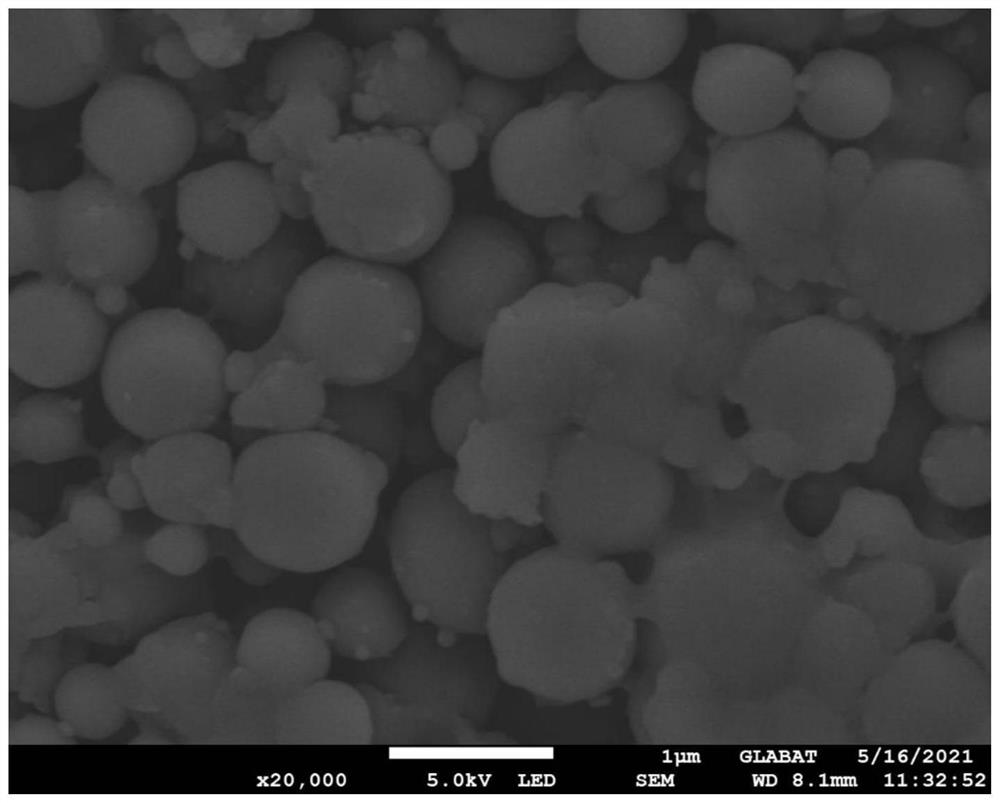

[0028] (1) Preparation of polyimide microspheres: Weigh the monomer pyromellitic dianhydride (PMDA) and the monomer 4,4'-diaminodiphenyl ether (ODA) in a molar ratio of 1:1, take N, N-dimethylformamide (DMF) was used as a solvent, mixed and stirred, and the reaction conditions were controlled to prepare a polyamic acid solution with a solid content of 15% and an apparent viscosity of 80 cp. Polyamic acid microspheres were prepared by electrostatic spraying in an electric field with an electric field strength of 1 kV / cm, then placed in a high-temperature furnace for imidization, and naturally cooled to room temperature to obtain polyimide microspheres.

[0029] (2) Co...

Embodiment 2

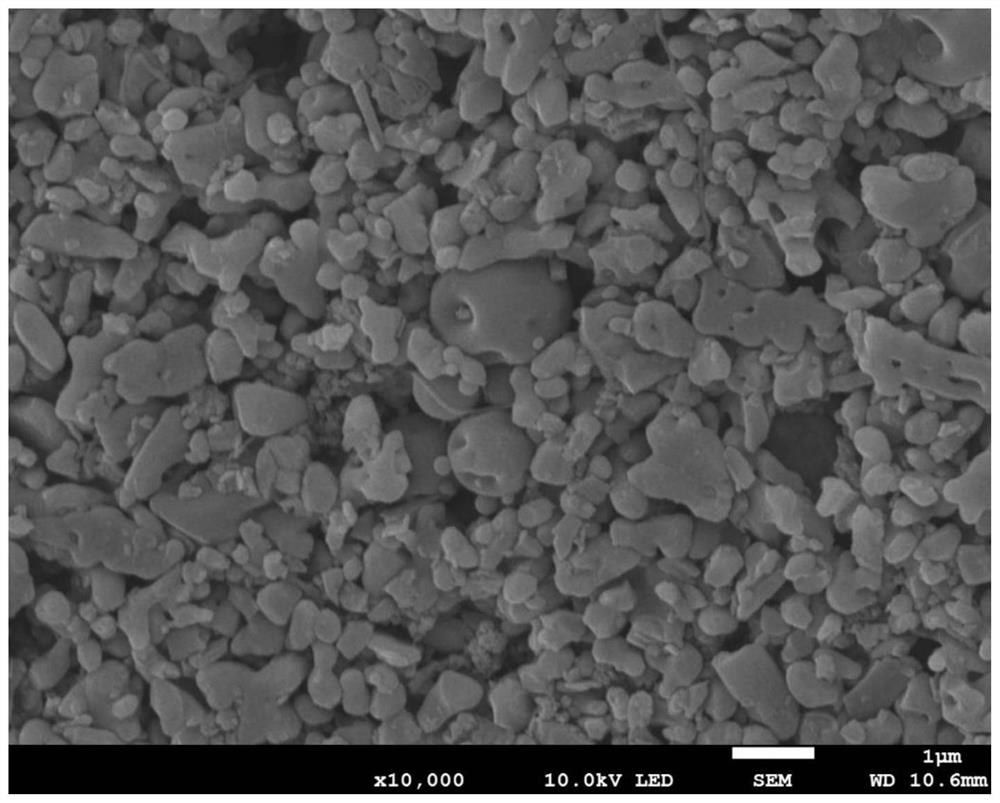

[0033] A polyimide microsphere / ceramic mixed-coated polyolefin separator, which uses a micro-recess coating process to coat the surface of a wet PE separator with a polyimide microsphere slurry, the slurry also contains a certain proportion of Ceramic Nanoparticles. The preparation method of the above-mentioned polyimide microsphere / ceramic mixed-coated polyolefin diaphragm comprises the following steps:

[0034](1) Preparation of polyimide microspheres: Weigh the monomer pyromellitic dianhydride (PMDA) and the monomer 4,4'-diaminodiphenyl ether (ODA) in a molar ratio of 1:1, take N, N-dimethylformamide (DMF) was used as a solvent, mixed and stirred, and the reaction conditions were controlled to prepare a polyamic acid solution with a solid content of 15% and an apparent viscosity of 80 cp. Polyamic acid microspheres were prepared by electrostatic spraying in an electric field with an electric field strength of 1 kV / cm, then placed in a high-temperature furnace for imidizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com