Polyester film with high barrier property and preparation and application thereof

A polyester film, high-barrier technology, applied in the field of film materials, can solve the problems of coating adhesion, increased production cost, unevenness, etc., to improve heat aging resistance and weather resistance, enhance impact resistance, and improve heat resistance. shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

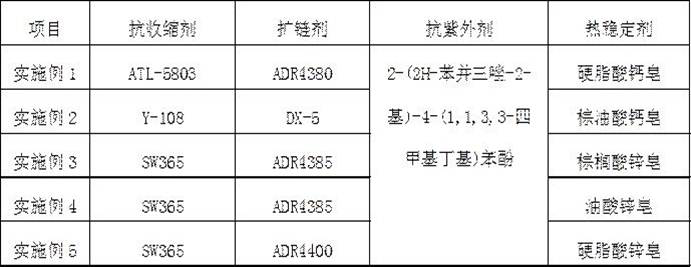

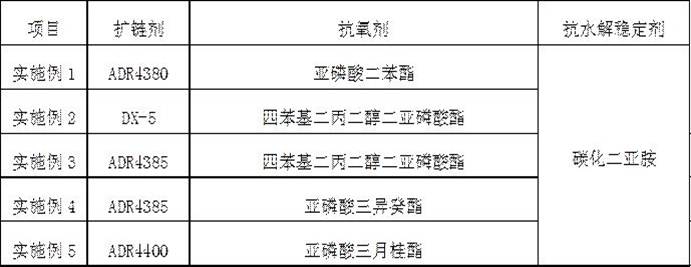

[0042] The polyester films of Examples 1-5 are all composed of an outer skin, an inner skin and a central core layer arranged between the outer skin and the inner skin, wherein the raw material components of the outer skin and the inner skin and their parts by weight are as shown in Table 1-1 shown.

[0043] project PET PEN PET-g-MAH Anti-shrinkage agent chain extender Anti-ultraviolet agent Heat stabilizers Example 1 70 30 10 2 1 0.1 0.2 Example 2 75 25 8 3 1 0.3 0.4 Example 3 78 22 5 4 2 0.5 0.5 Example 4 82 18 3 4 2 0.5 0.6 Example 5 85 15 1 5 3 0.6 0.8

[0044] The intrinsic viscosities of PET and PEN used in the raw material components of the outer and inner layers of Examples 1-5 are shown in Table 1-2 below.

[0045] project Example 1 Example 2 Example 3 Example 4 Example 5 PET intrinsic viscosity 0.6 dL / g 0.62 dL / g 0.65 dL / g 0.68 dL / g 0.7 dL / g P...

Embodiment 5

[0060] In embodiment 5, PET and dibenzoyl peroxide, maleic anhydride, two [ethyl-3-(3,5-di-tert-butyl-4-hydroxyphenyl)] 2,2-oxalamide by mass ratio The ratio is 100:0.1:5:0.3, and the temperature of the twin-screw extruder is controlled at 290°C.

[0061] The starch-modified superfine montmorillonite used in the raw material components of the core layer of embodiment 1-5 is prepared by the following method:

[0062] Grind montmorillonite, pass through a 1000-mesh sieve, add the sieved montmorillonite and starch into the aqueous solution containing sodium dodecylsulfonate, stir and mix evenly at 60°C, and then ultrasonically disperse at 40°C , to obtain a stable suspension; then use a high-pressure spray dryer to dry the suspension to solidify the starch, that is, to obtain a starch-modified ultrafine montmorillonite.

[0063] In the above-mentioned process of preparing starch-modified ultrafine montmorillonite:

Embodiment 1

[0064] In embodiment 1, add the sodium lauryl sulfate of 1 weight part, the montmorillonite of 10 weight parts and the starch of 18 weight parts in the water of every 100 weight parts;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com