High-performance flexible composite nonwoven fabric membrane for lithium ion battery, as well as preparation method and application of membrane

A lithium-ion battery and non-woven membrane technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of complex preparation process, reduction of the maximum pore size of the non-woven membrane, and high membrane cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

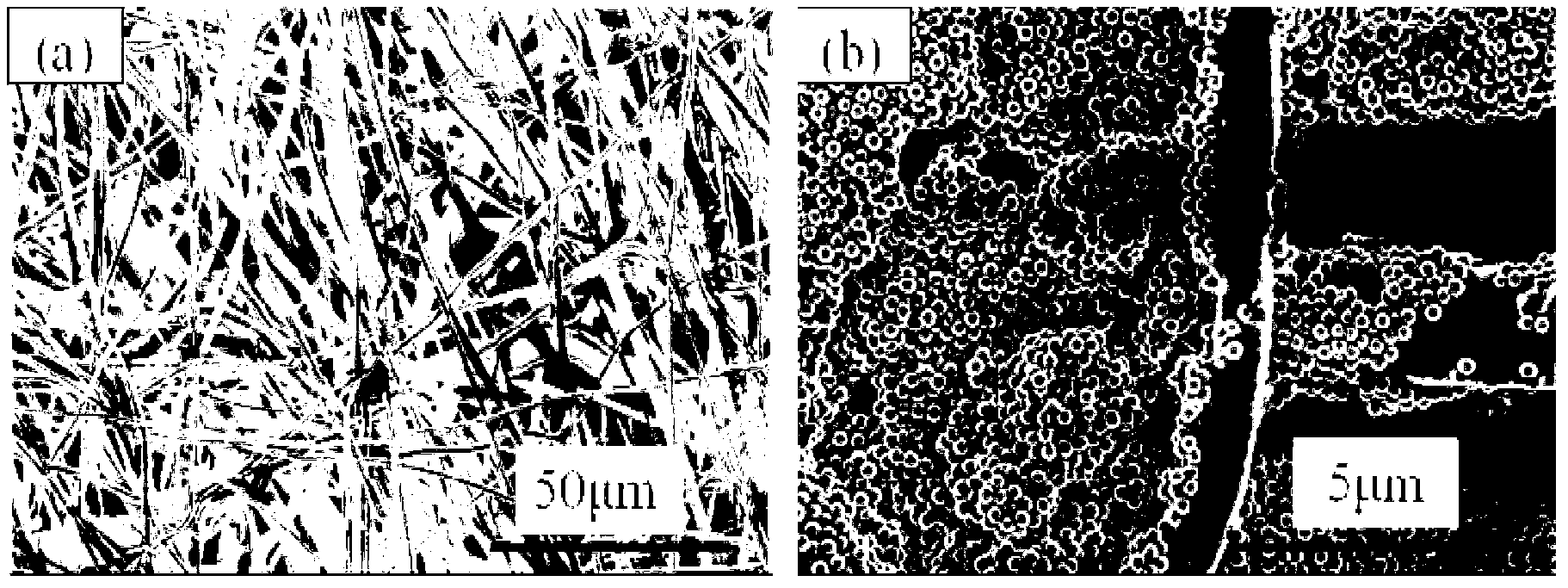

[0085] A high-performance flexible composite non-woven fabric film with good dimensional stability, prepared by the following method:

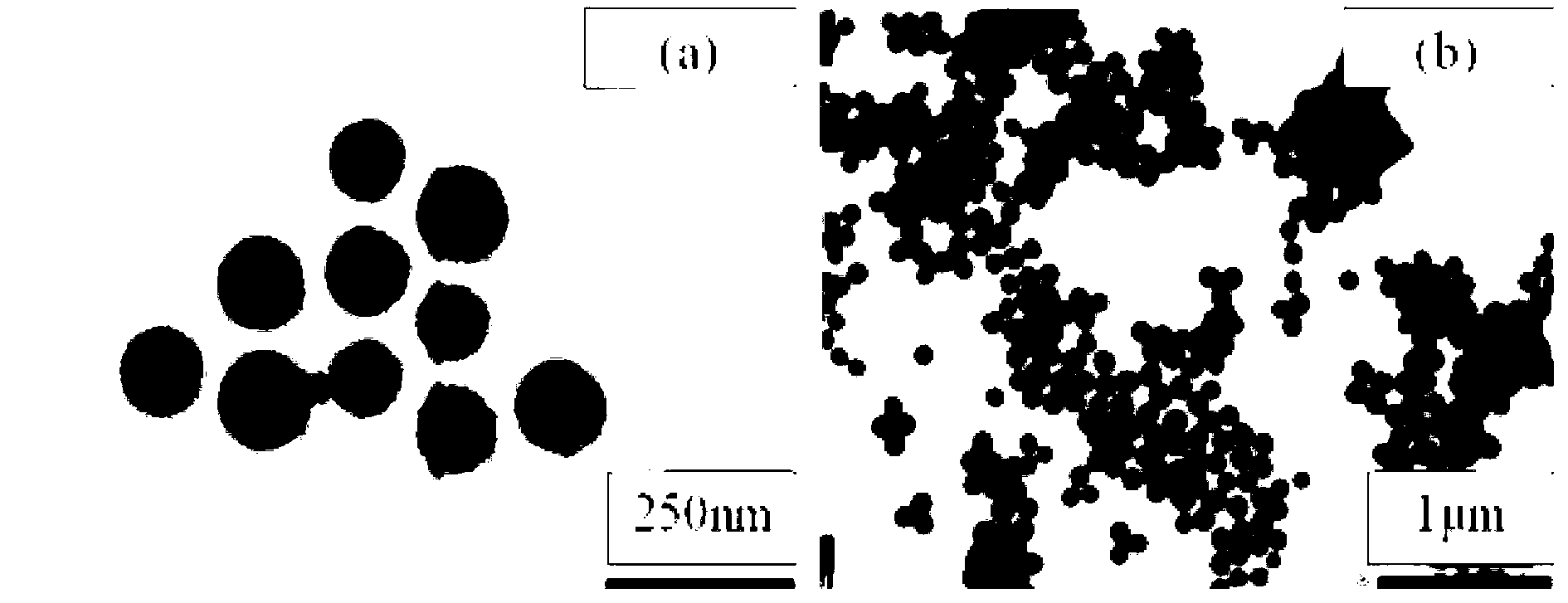

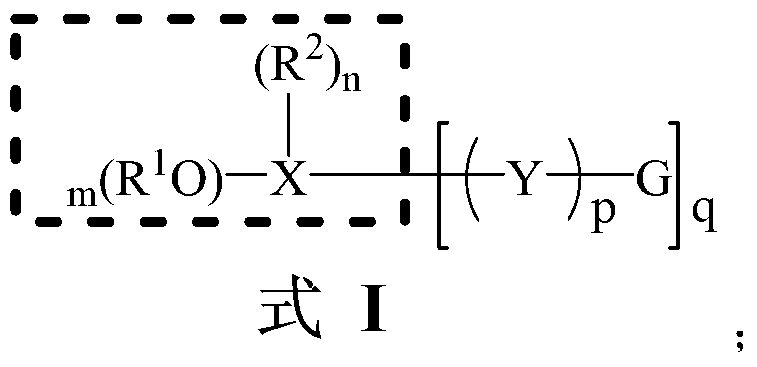

[0086] According to the mass ratio, 10 parts of 2-(3,4-epoxycyclohexyl)-ethyltrimethoxysilane (ECTS) (see formula IV for structure), 10 parts of diphenylsilanediol (DPSD) (see formula for structure V), 40 parts of polyethylene glycol dimethyl ether and 0.2 parts of barium hydroxide were mixed, and reacted at 80° C. for 4 hours. Disperse 40 parts of 200nm silicon dioxide in ethanol, then add it to the above system, continue to react at 80°C for 8 hours, cool to room temperature, add 0.05 parts of photoinitiator diaryliodonium salt, and remove the bulk under reduced pressure. part of ethanol to obtain a functional coating solution. Roll-coat the functional coating liquid on the PP non-woven film with hydroxyl groups (thickness 15 μm, area density 18±4g / m2) 2, porosity ≥ 65%), the thickness of the composite film is controlled at about 30 μm, an...

Embodiment 2

[0118] A kind of high-performance flexible composite non-woven fabric membrane with good dimensional stability, its preparation method is except that used feedstock is 15 parts of ECTS, 5 parts of DPSD, 50 parts of polyethylene glycol dimethyl ether, 40 parts of 100nm dioxide Silicon, the reaction temperature in step 1 is 60°C, methyl hexahydrophthalic anhydride is used as the curing agent during curing, heat curing is used instead of light curing as the curing method, and the heat curing condition is 90°C for 16 hours. Other operations and raw materials are the same. With embodiment 1.

[0119] Determination of the Gurley value of the high-performance flexible composite non-woven fabric film with good dimensional stability, the liquid absorption rate to the electrolyte, MacMullin number (Nm) and thermal shrinkage rate of the high-performance flexible composite non-woven fabric film prepared in this example, and using the prepared in this example The composite separator was ma...

Embodiment 3

[0121] A kind of high-performance flexible composite non-woven fabric film with good dimensional stability, its preparation method is except that the used feeding amount is 10 parts of ECTS, 5 parts of DPSD, 50 parts of polyethylene glycol dimethyl ether, 35 parts of 100nm aluminum oxide , the reaction temperature in step 1 is 90°C, and a PP non-woven membrane with amino groups on the surface (thickness 15μm, surface density 18±4g / m 2 , porosity ≥ 65%) to replace the PP non-woven fabric film with hydroxyl groups on the surface, no light curing agent and heat curing agent are added during curing, and heat curing is used instead of light curing. The heat curing condition is 100°C for 8 hours, and other operations All with embodiment 1 with raw material.

[0122] Measure the Gurley value of the high-performance flexible composite non-woven fabric film with good dimensional stability, the liquid absorption rate to the electrolyte, MacMullin number and thermal shrinkage rate of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com