Polyolefin composite separator, preparation method thereof, and lithium-ion battery

A composite diaphragm and polyolefin technology, applied in the field of lithium-ion batteries, can solve the problems of low electrolyte wettability, low liquid absorption rate, and accelerated battery thermal runaway, so as to improve thermal shrinkage resistance, gas permeability, and Effect of Magnification Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

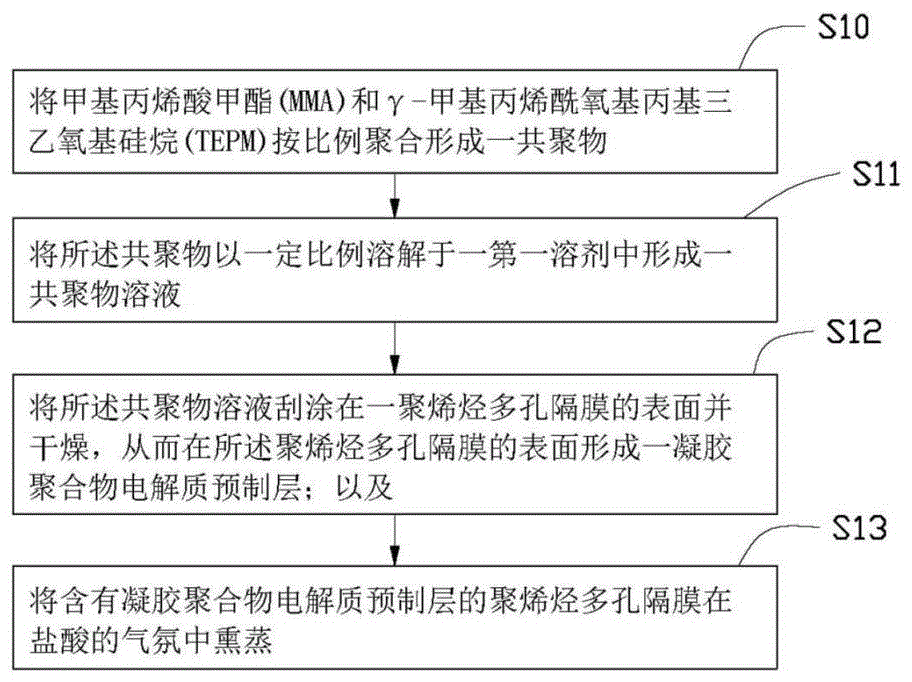

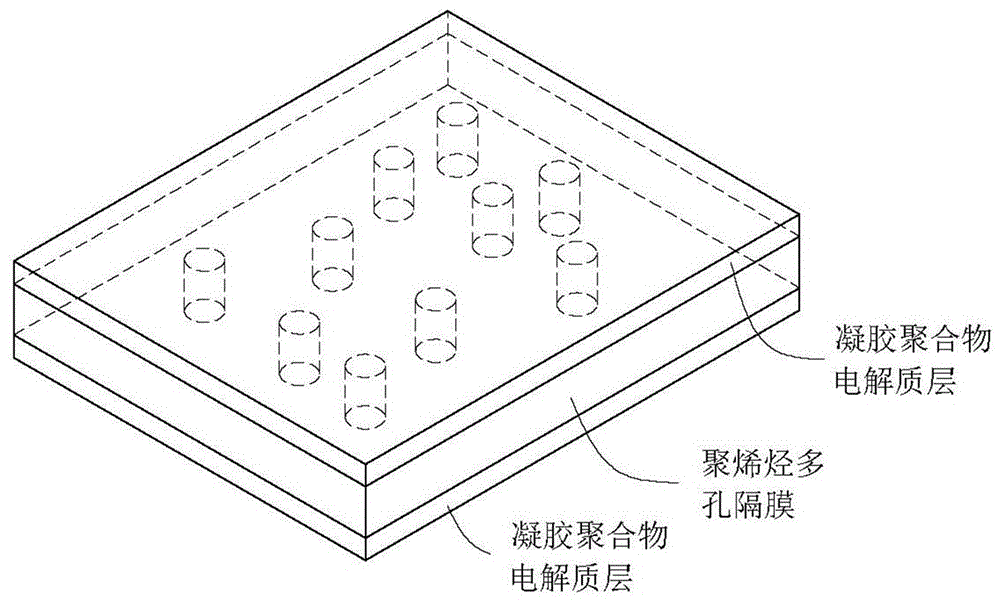

[0014] Please refer to Figure 1-2 , the embodiment of the present invention provides a preparation method of a polyolefin composite diaphragm, comprising:

[0015] S10, methyl methacrylate (MMA) and γ-methacryloxypropyltriethoxysilane (TEPM) are polymerized in proportion to form a copolymer, and the molecular formula of the copolymer is:

[0016] , where m and n are integers;

[0017] S11, dissolving the copolymer in a first solvent in a certain proportion to form a copolymer solution;

[0018] S12, scrape-coat the copolymer solution on the surface of the polyolefin porous membrane and dry it, so as to form a gel polymer electrolyte prefabricated layer on the surface of the polyolefin porous membrane; and

[0019] S13, fumigate the polyolefin porous separator containing the gel polymer electrolyte prefabricated layer in the atmosphere of hydrochloric acid.

[0020] The step S10 includes the following steps:

[0021] S101, mixing methyl methacrylate and γ-methacryloxypro...

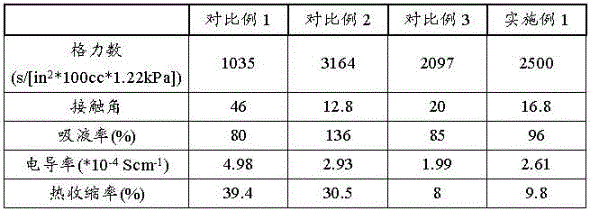

Embodiment 1

[0042] Mix methyl methacrylate and γ-methacryloxypropyltriethoxysilane evenly at a molar ratio of 1:1, then add a certain amount of azobisisobutyronitrile (AIBN), at 80°C Stirring polymerization forms a copolymer prepolymer; the copolymer prepolymer is dissolved in tetrahydrofuran to form a mixed solution of the copolymer prepolymer, and the mixed solution of the copolymer prepolymer is added to ethanol / water (volume Precipitation in a mixed solvent with a ratio of 1:1), and repeated three times, so as to obtain the precipitation of a copolymer of polymethyl methacrylate-polyγ-methacryloxypropyltriethoxysilane; the copolymerization The substance is dissolved in tetrahydrofuran to form a copolymer solution with a concentration of about 10%; the copolymer solution is scraped on the two surfaces of a Celgard-2325 type diaphragm and dried; the Celgard-2325 type diaphragm coated with the copolymer solution The diaphragm was fumigated in a concentrated hydrochloric acid atmosphere f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com