Polyolefin resin composition, preparation method thereof, insulating material for cable, cable

An insulating material, polyolefin technology, applied in the field of polyolefin resin composition, can solve the problems of equipment life influence, surface quality reduction, increase equipment temperature, etc., achieve excellent insulation heat shrinkage performance, improve heat shrinkage resistance performance, strengthen effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

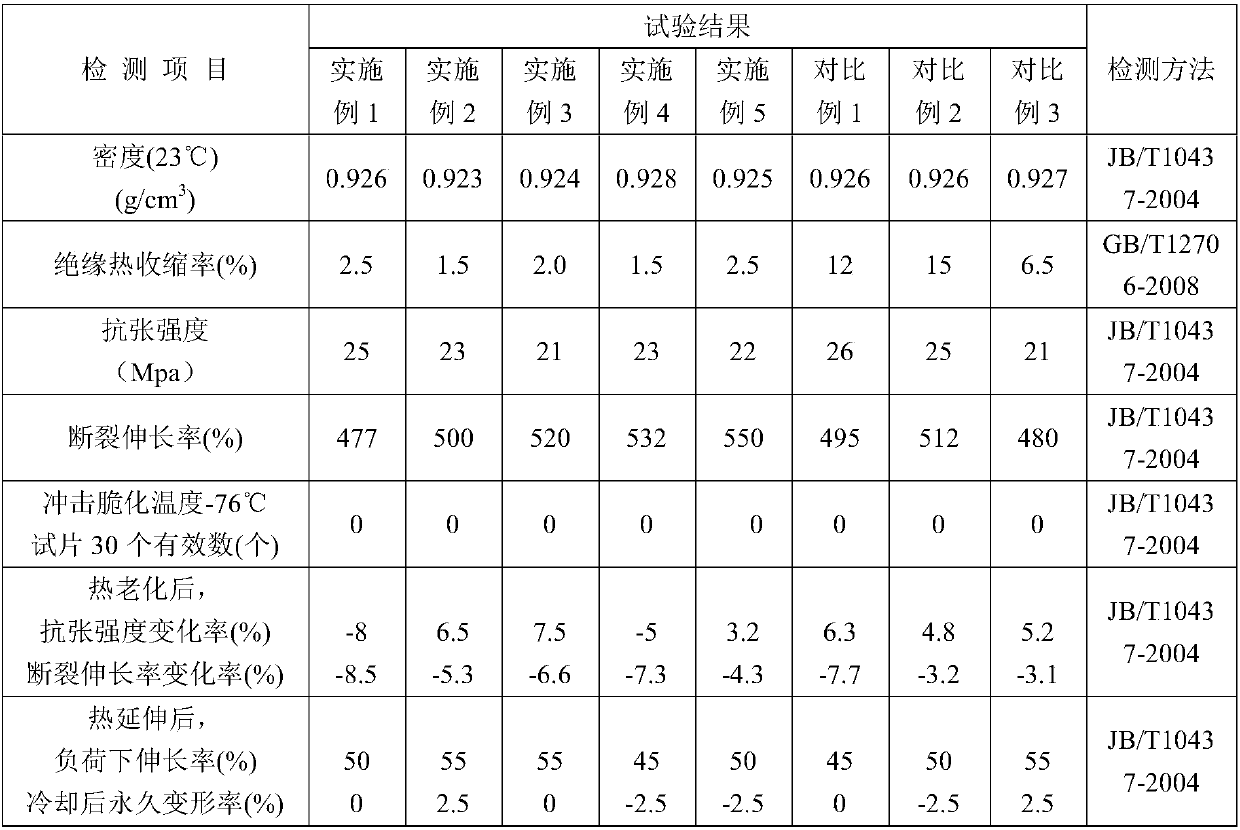

Examples

preparation example Construction

[0047] The present invention also provides a preparation method of the polyolefin resin composition according to the present invention, which comprises: mixing and reacting each component and then granulating to obtain the polyolefin resin composition.

[0048] According to the method of the present invention, polyolefins, coupling agents, initiators, antioxidants, lactam ring compounds and / or acid anhydride compounds are uniformly mixed in a high-speed kneader, and then added in sequence at a temperature of 180-220°C. Put it into the reaction kettle, use a mixer to mix evenly, and then enter the screw machine to granulate, so that the polyolefin and the coupling agent (such as: silane coupling agent) undergo grafting reaction, and then injection molding or extrusion to obtain the finished product. Finally, the finished product is exposed to moisture or hot water, thereby causing the hydrolysis of the silane, and forming Si-O-Si bond crosslinks through polycondensation reaction...

Embodiment 1

[0057] The low density polyethylene of 20 weight parts, the medium density polyethylene of 20 weight parts, the high density polyethylene of 20 weight parts, the linear low density polyethylene of 40 weight parts, the dicumyl peroxide of 1.4 weight parts, 6.0 Parts by weight of vinyltriethoxysilane, 0.4 parts by weight of 1,2-bis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine, 1.7 parts by weight of cis-butyl The olefinic anhydride was sequentially added to a high-speed kneader at a temperature of 200° C., mixed uniformly by a mixer, and then entered into a twin-screw extruder for granulation to obtain polyolefin resin composition I.

Embodiment 2

[0059] 33 parts by weight of low-density polyethylene, 23 parts by weight of medium-density polyethylene, 44 parts by weight of linear low-density polyethylene, 1.7 parts by weight of dicumyl peroxide, 3.5 parts by weight of vinyl-tri(2 -Methoxyethoxy)silane, 0.1 parts by weight of dilauryl thiodipropionate, and 1.7 parts by weight of butyrolactam were sequentially added to the reaction kettle at a temperature of 200° C., and mixed uniformly with a stirrer, Then enter the screw machine for granulation to obtain polyolefin resin composition II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com