Shrinkage-resistant graphene oxide-based porous battery diaphragm and preparation method thereof

A technology of battery diaphragm and graphene, which is applied in the direction of lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problems of easy falling of ceramic coatings, loss of heat resistance, safety accidents, etc., and increase thermal stability Performance and safety, enhanced heat shrinkage resistance, and guaranteed dimensional integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

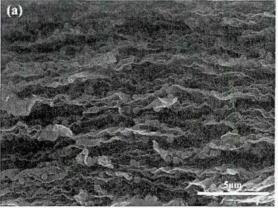

Image

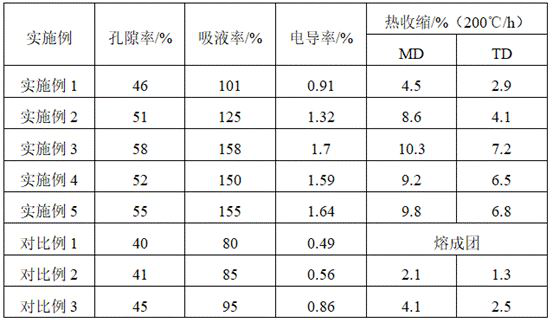

Examples

Embodiment 1

[0030] Step 1: Add 200g of graphene oxide and 1000g of polyether polyol into the reaction kettle in sequence, add 0.5g of p-toluenesulfonic acid, set the reaction temperature to 130°C, and the reaction time to 14 hours, filter and wash to obtain GO-HBPE powder; Ultrasonically disperse 500g of GO-HBPE powder in water for 3.5 hours to form a homogeneous phase, add 0.3g of polystyrene microspheres with a diameter of about 800nm, and stir for 2 hours to obtain an emulsion; vacuum filter the emulsion , set the pressure of the vacuum filtration to be -50kPa to obtain the primary membrane;

[0031] Step 2: Immerse the primary film in toluene for extraction, dissolve the PS pellets, set the temperature at 60°C and heat and dry for 1 hour to obtain a porous battery separator.

Embodiment 2

[0033] Step 1: Add 200g of graphene oxide and 1000g of polyether polyol into the reaction kettle in sequence, add 0.5g of p-toluenesulfonic acid, set the reaction temperature to 130°C, and the reaction time to 14 hours, filter and wash to obtain GO-HBPE powder; Ultrasonically disperse 500g of GO-HBPE powder in water for 3.5 hours to form a homogeneous phase, add 0.4g of polystyrene microspheres with a diameter of about 800nm, and stir for 2 hours to obtain an emulsion; vacuum filter the emulsion , set the pressure of the vacuum filtration to be -50kPa to obtain the primary membrane;

[0034] Step 2: Immerse the primary film in toluene for extraction, dissolve the PS pellets, set the temperature at 60°C and heat and dry for 1 hour to obtain a porous battery separator.

Embodiment 3

[0036] Step 1: Add 200g of graphene oxide and 1000g of polyether polyol into the reaction kettle in sequence, add 0.5g of p-toluenesulfonic acid, set the reaction temperature to 130°C, and the reaction time to 14 hours, filter and wash to obtain GO-HBPE powder; Ultrasonically disperse 500g of GO-HBPE powder in water for 3.5 hours to form a homogeneous phase, add 0.5g of polystyrene microspheres with a diameter of about 800nm, and stir for 2 hours to obtain an emulsion; vacuum filter the emulsion , set the pressure of the vacuum filtration to be -50kPa to obtain the primary membrane;

[0037] Step 2: Immerse the primary film in toluene for extraction, dissolve the PS pellets, set the temperature at 60°C and heat and dry for 1 hour to obtain a porous battery separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com