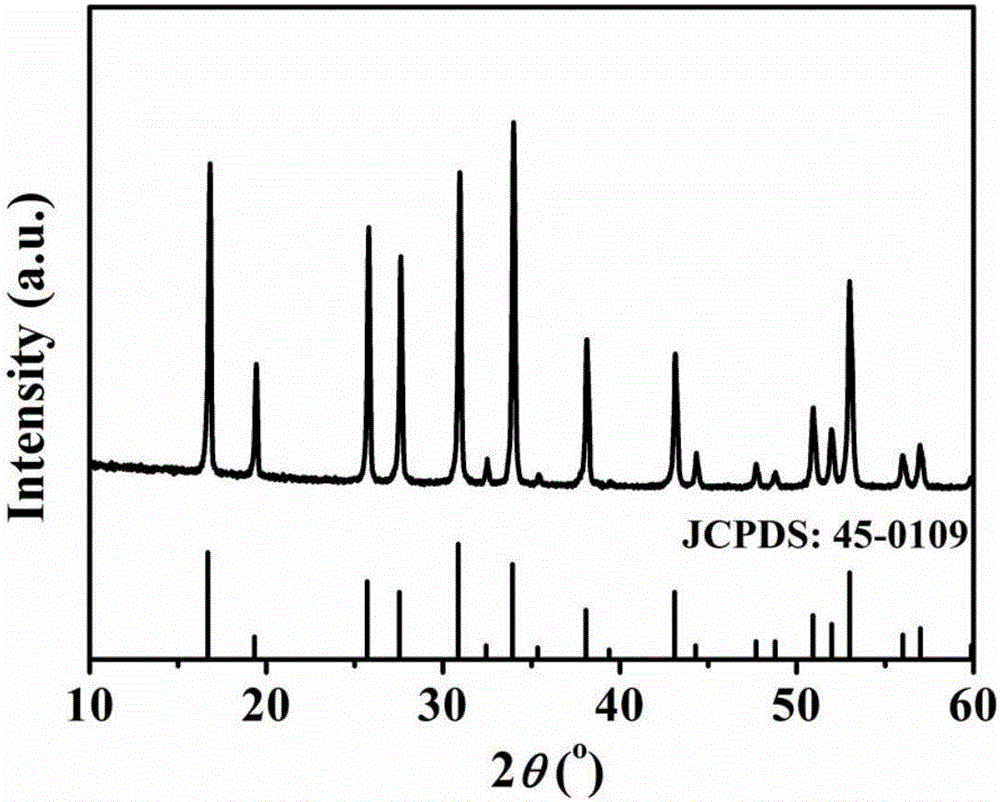

Li7La3Zr2O12 ion conductor ceramic fiber and preparation method thereof

A technology of lithium lanthanum zirconium oxide and ion conductors, which is applied in the direction of inorganic raw materials such as artificial filaments, can solve the problems of ion conductor ceramic fiber chemical structure, shape size and electrical conductivity differences, complex preparation process, poor stability, etc., to achieve compensation Li-ion conductivity, enhanced rate performance, and reduced clogging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of lithium lanthanum zirconium oxide ion conductor ceramic fiber, comprising the following steps:

[0029] 1) lithium carbonate, lanthanum oxide, zirconyl nitrate, nitric acid solution and absolute ethanol are mixed and heated to obtain a mixed solution;

[0030] 2) Mix citric acid and ethylene glycol with the mixed solution obtained in step 1) to obtain a lithium lanthanum zirconium oxygen precursor, wherein the molar ratio of lithium carbonate, lanthanum oxide, zirconyl nitrate, ethylene glycol and citric acid is 7 :3:4:28:14, stirring the lithium lanthanum zirconium oxygen precursor at a constant temperature to obtain a precursor sol;

[0031] 3) mixing and stirring the water-soluble polymer with the precursor sol obtained in the step 2) to obtain the spinning sol;

[0032] 4) Calcining the spinning sol obtained in step 3) after spinning to obtain ion conductor ceramic fibers.

[0033] The present invention d...

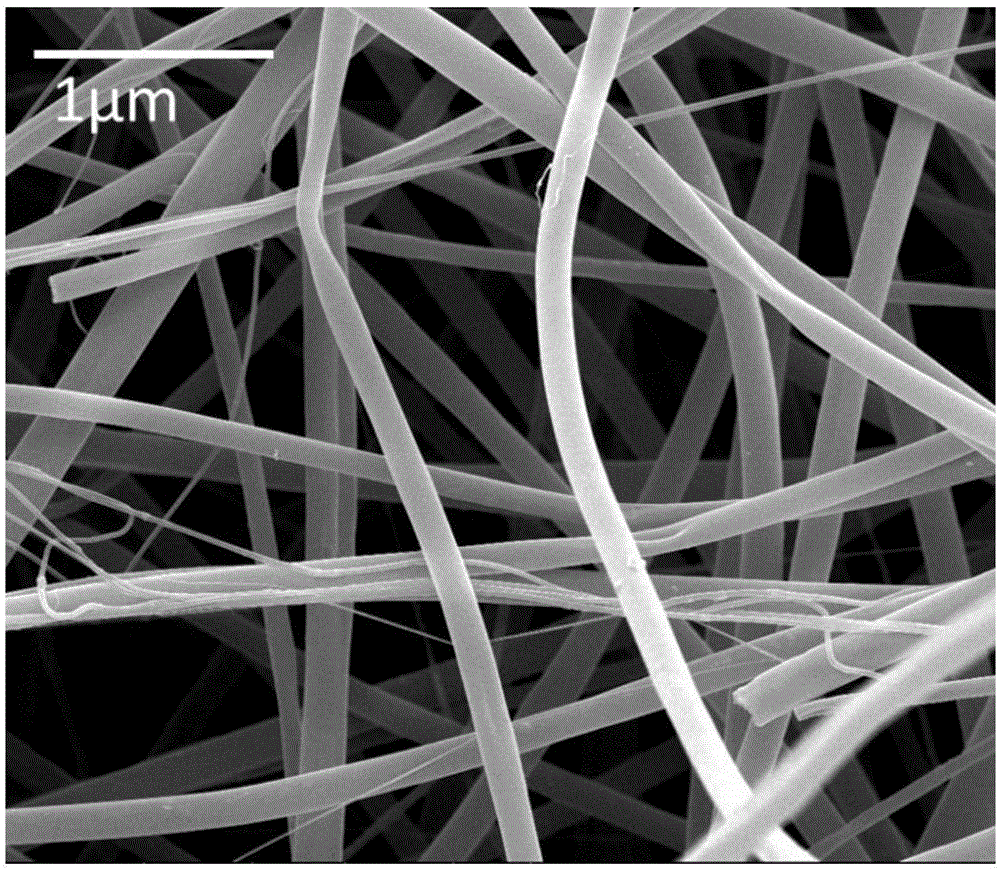

Embodiment 1

[0047] Weigh lithium carbonate (Li 2 CO 3 )5.69g, lanthanum oxide (La 2 o 3 ) 9.77g, zirconium oxynitrate (ZrO(NO 3 ) 2 )9.25g, lithium carbonate (Li 2 CO 3 ), lanthanum oxide (La 2 o 3 ) was dissolved in 80g concentration of 15% dilute nitric acid solution, zirconium oxynitrate (ZrO(NO 3 ) 2 ) was dissolved in 20g of absolute ethanol, wherein Lithium Carbonate weighed 10% more to compensate for the volatilization of lithium under high temperature.

[0048] Mix the above-mentioned nitric acid solution dissolved in lithium carbonate and lanthanum oxide with absolute ethanol dissolved in zirconium oxynitrate, and stir in a constant temperature water bath environment at 50°C, then add 53.80g of citric acid and 8.69g of ethylene glycol, and keep the temperature constant Stirred for 12h to obtain a sol.

[0049] 50 g of PVP solution with a mass concentration of 10% was weighed and mixed with the obtained sol, and stirred thoroughly for 24 hours. The obtained sol was use...

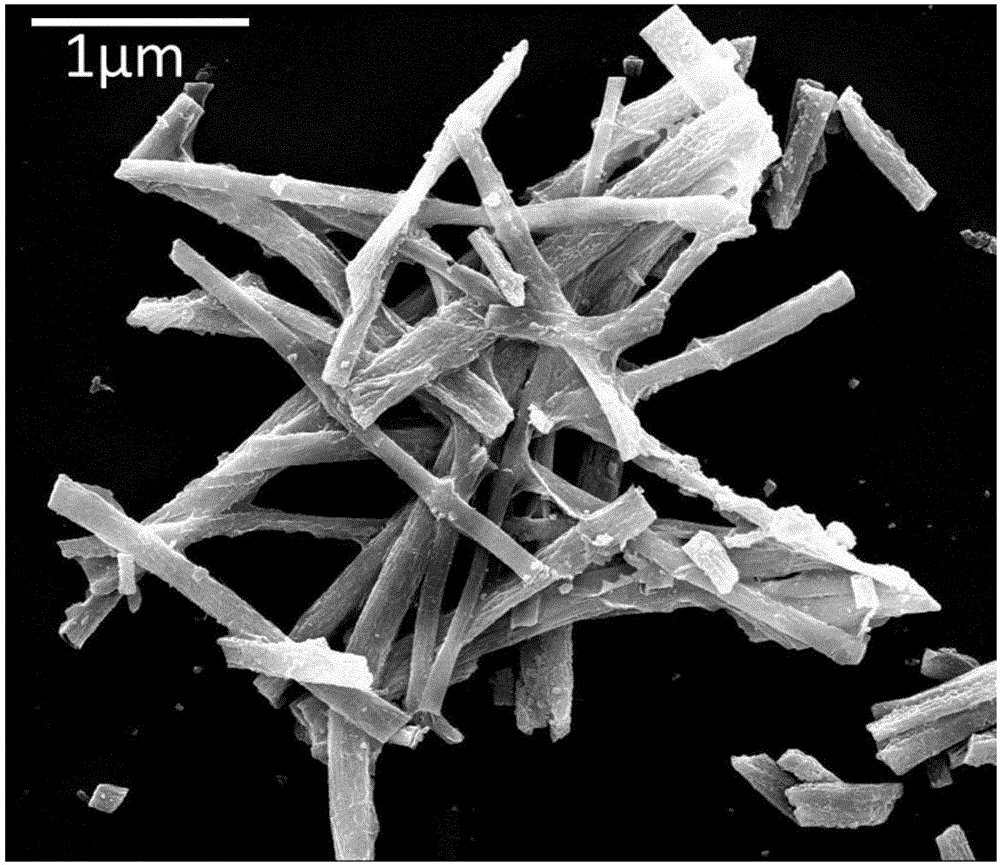

Embodiment 2

[0053] Weigh lithium carbonate (Li 2 CO 3 )5.69g, lanthanum oxide (La 2 o 3 ) 9.77g, zirconium oxynitrate (ZrO(NO 3 ) 2 )9.25g, lithium carbonate (Li 2 CO 3 ), lanthanum oxide (La 2 o 3 ) was dissolved in 50g concentration of 20% dilute nitric acid solution, zirconium oxynitrate (ZrO(NO 3 ) 2 ) was dissolved in 40g absolute ethanol, wherein Lithium Carbonate weighed 10% more to compensate for the volatilization of lithium under high temperature.

[0054] Mix the above-mentioned nitric acid solution dissolved in lithium carbonate and lanthanum oxide with absolute ethanol dissolved in zirconium oxynitrate, and stir in a constant temperature water bath environment at 80°C, then add 53.80g of citric acid and 8.69g of ethylene glycol, and keep the temperature constant Stirred for 24h to obtain a sol.

[0055] Weigh 45g of PVP solution with a mass concentration of 10%, mix with the obtained sol, and stir thoroughly for 48h. The obtained sol was used for air spinning at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com