Composite diaphragm and preparation method thereof as well as battery and object with composite diaphragm

A technology for composite diaphragms and objects, applied in the field of objects, composite diaphragms and their preparation, and batteries, to achieve the effects of high surface energy, good hydrophilicity, and improved affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Finally, the preparation method of above-mentioned composite diaphragm comprises the following steps:

[0044] Preparation of electrospinning film: dry the powdery polymer mixture and add it to the solvent N,N-dimethylformamide, stir it to make it fully dispersed to obtain an electrospinning solution, and perform electrospinning under the electrospinning equipment silk, to prepare the electrospun film. Among them, the electrospinning equipment adopts a spinning rate of 0.2-1.2ml / h, a voltage of 14-20KV, an ambient humidity of ≤30%, and a distance of 10-20cm from the spinning nozzle to the receiving plate. Dry at ℃ for 1-3h / 13.

[0045] Preparation of nano-coating: preparing a mixed solution of DMF and absolute ethanol, adding the LATP nano-material into the mixed solution, stirring and dispersing to prepare the nano-coating. Among them, LAPT nanomaterials are prepared by the following method: Li 2 CO 3 , AlOOH, TiO 2 , NH 4 h 2 PO 4 The powder is added into abso...

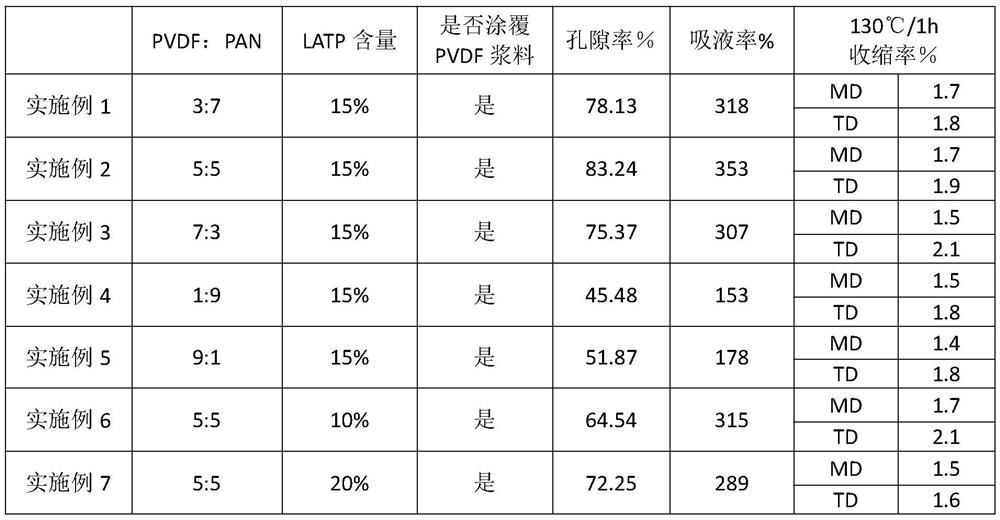

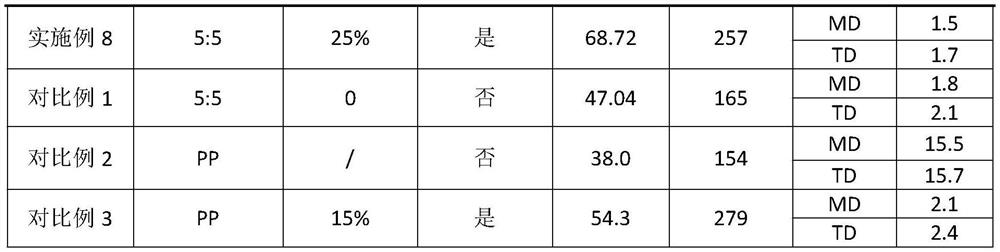

Embodiment 1

[0050] 3g of PVDF and 7g of PAN were dissolved in 55g of DMF to prepare a PVDF-PAN spinning solution, and stirred at a constant speed for 24 hours at room temperature to obtain a PVDF-PAN mixture. The spinning rate is 1.2ml / h, the setting voltage is 20KV, the ambient humidity (RH) is ≤30%, the distance between the spinning nozzle and the receiving plate is 20cm, collected by a drum, and dried at 70°C for 2.5h to obtain PVDF-PAN electrospun film.

[0051] According to the molar ratio Li 2 CO 3 :AlOOH:TiO 2 : NH 4 h 2 PO 4 1.3:0.3:1.7:1 was added with absolute ethanol and mixed on a planetary ball mill, and the mixture was dried at 80° C. for 5 hours to obtain a precursor material. The precursor was first heated to 300°C for 2 hours in a muffle furnace at a heating rate of 5°C / min, then heated to 700°C for 4 hours and then naturally cooled to room temperature. The calcined LATP block material was taken out, ground and sieved (100 mesh), you can get LATP[Li 1.3 al 0.3 Ti...

Embodiment 2

[0056] The difference from Example 1 is that 5g of PVDF and 5g of PAN are dissolved in 55g of DMF to prepare a PVDF-PAN spinning solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com