Alkyd prepolymer as well as preparation method and application of alkyd prepolymer

A prepolymer, alkyd technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problem of insufficient hydrophilicity of sulfonated polyester diol and viscosity of sulfonated polyester polyol. Large, unable to react with isocyanates, etc., to achieve the effect of less addition, good hydrophilicity and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

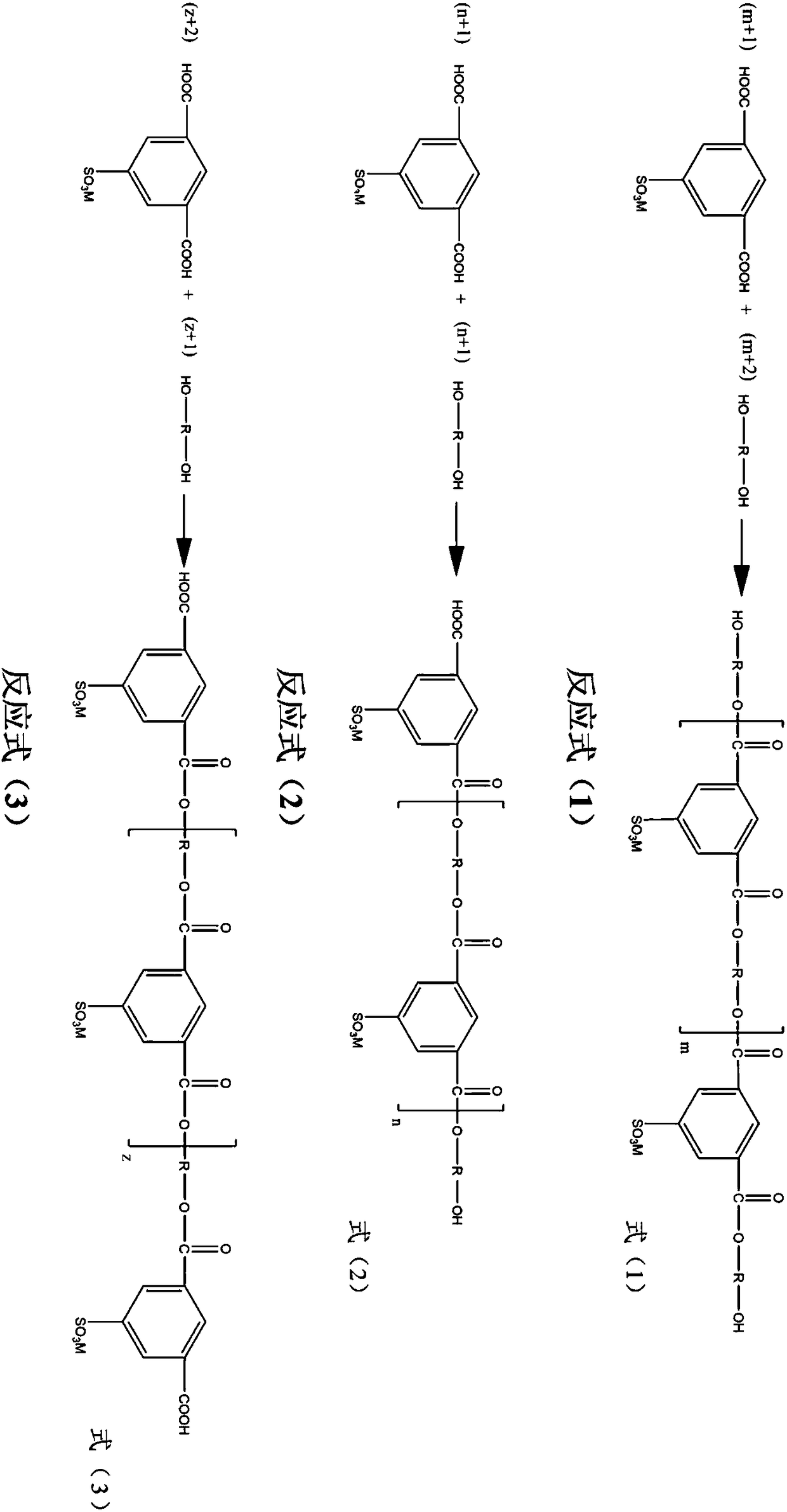

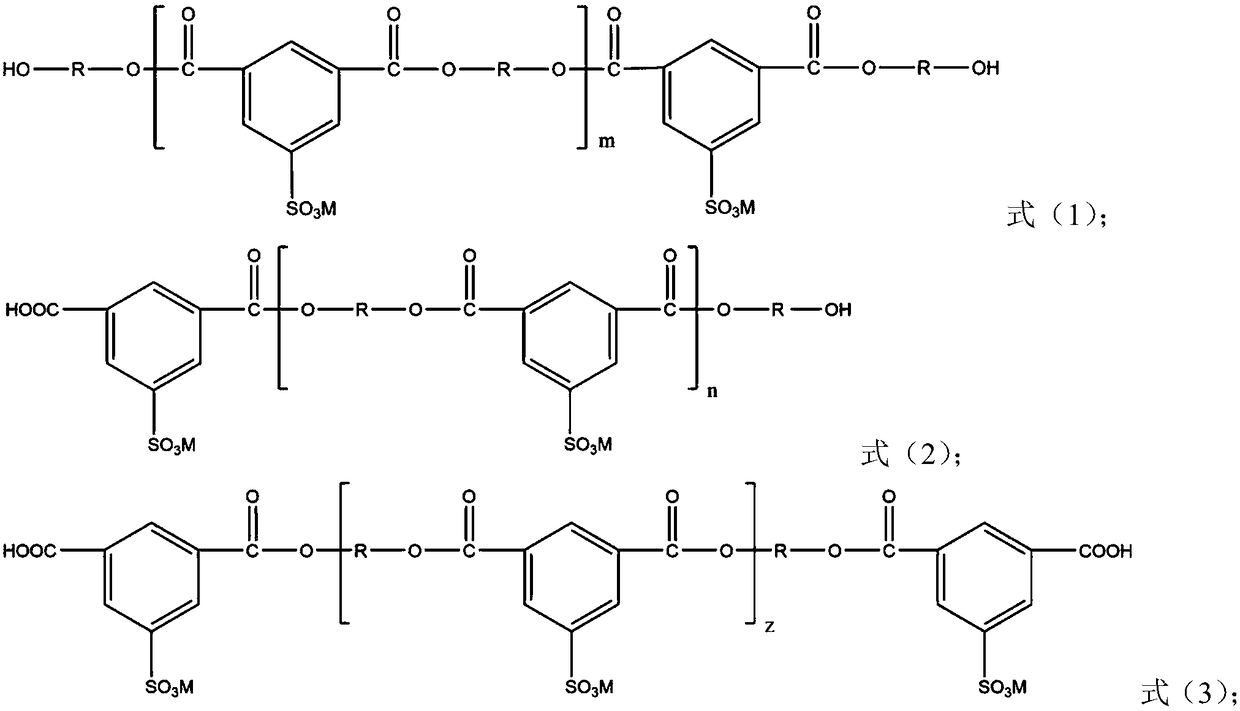

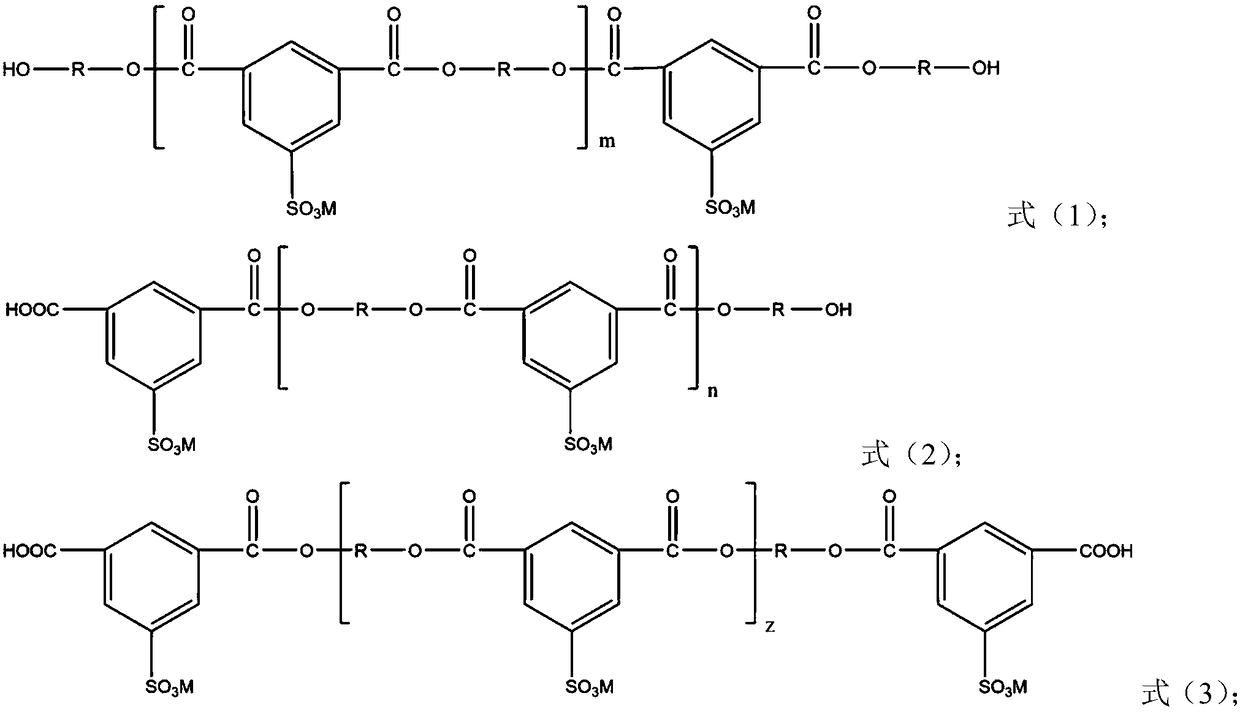

[0050] The preparation method of the alkyd prepolymer is to prepare the alkyd prepolymer through esterification using dicarboxylate sulfonate and small molecular diol as raw materials.

[0051] Further, the preparation method of this alkyd prepolymer comprises the following steps:

[0052] a) Add dicarboxysulfonate, small molecule glycol and water into the reactor, stir, heat up to 90°C to 97°C, mix and dissolve;

[0053] b) Add antioxidant and catalyst, close the reactor, pass in protective gas, raise the temperature of the reactor to 100°C-180°C, and carry out the esterification reaction for 10h-20h;

[0054] c) adding a solvent into the reactor to dissolve the esterification product obtained in step b), purifying by vacuum distillation, and discharging to obtain an alkyd prepolymer.

[0055] Preferably, in step a) of the preparation method, the mass ratio of dicarboxysulfonate to water is 1: (0.5-2.0); the molar ratio of dicarboxysulfonate to small molecule glycol is 1: (1...

Embodiment 1

[0078] a) Add 214g of distilled water, 168g of 1,4-butanediol, and 200g of sodium isophthalic acid-5-sulfonate into the reactor, stir, heat up to 90-97°C, mix and dissolve;

[0079] b) Add 0.4g of antioxidant 1010 and 0.2g of tetrabutyl titanate, close the reactor, feed nitrogen, and increase the steam volume when the temperature in the kettle rises to 107°C, and control the reflux temperature of the condenser water outlet to 100~ 102°C, continue to raise the temperature in the reactor to 120-130°C, and carry out the esterification reaction for 15 hours. During this period, the reflux temperature of the water outlet of the condenser is maintained at 100-102°C to control the water outlet rate of the condensed water until the water output is close to When adding water, start to measure the acid value, stop the reaction when the set acid value is reached, and turn off the cooling water of the condenser;

[0080] c) Add 122g of polyethylene glycol (molecular weight: 400) into the ...

Embodiment 2

[0083] a) Add 230g of distilled water, 127.2g of diethylene glycol, 104.2g of neopentyl glycol, and 200g of isophthalic acid-5-sodium sulfonate into the reactor, stir, heat up to 90-97°C, mix and dissolve;

[0084] b) Add 0.5g of antioxidant 1010 and 0.3g of tetrabutyl titanate, close the reactor, feed nitrogen, and increase the steam volume when the temperature in the kettle rises to 107°C, and control the reflux temperature of the water outlet of the condenser to 100- 102°C, continue to raise the temperature in the reactor to 160-170°C, and carry out the esterification reaction for 17 hours, during which the reflux temperature of the water outlet of the condenser is maintained at 100-102°C to control the water outlet rate of the condensed water until the water output is close to When adding water, start to measure the acid value, stop the reaction when the set acid value is reached, and turn off the cooling water of the condenser;

[0085]c) Add 135g of polyethylene glycol (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com