Polyolefin composite membrane and preparation method thereof as well as lithium ion battery

A technology of composite diaphragm and polyolefin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

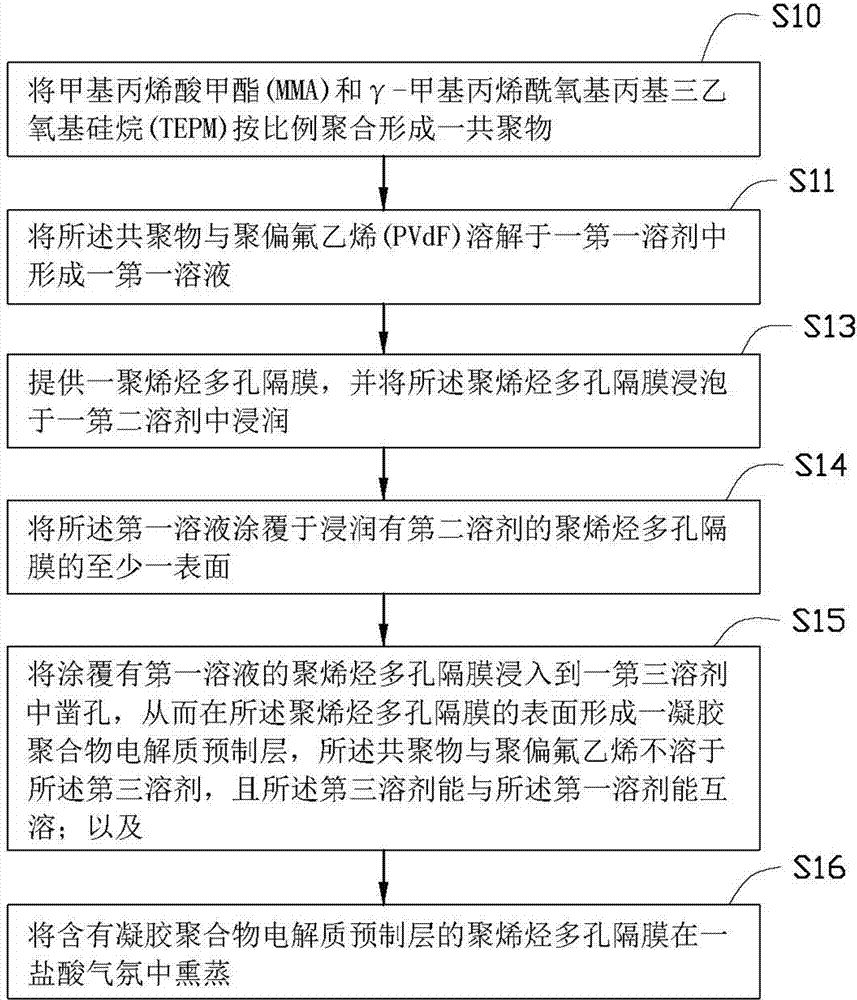

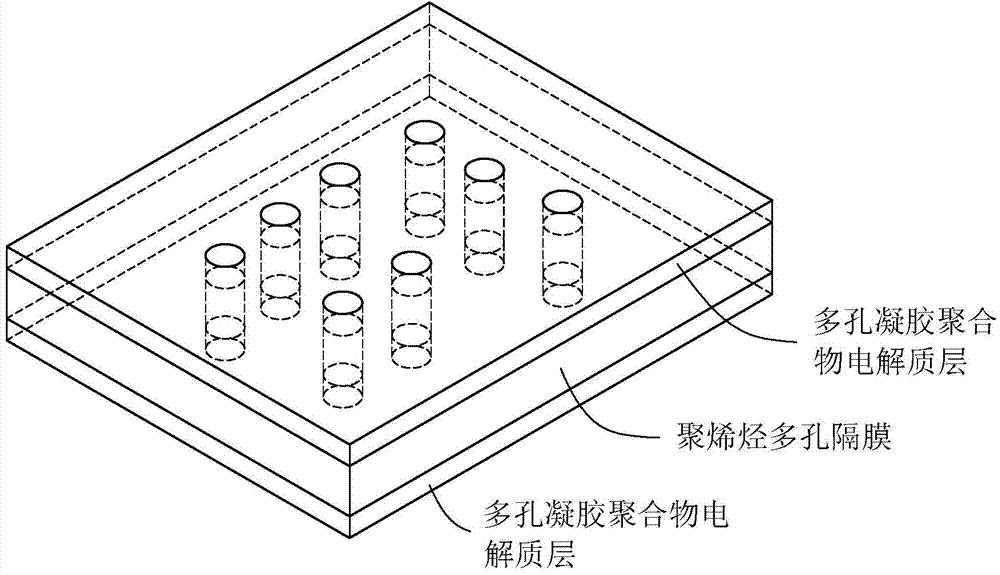

[0014] Please refer to Figure 1-2 , the embodiment of the present invention provides a preparation method of a polyolefin composite diaphragm, comprising:

[0015] S10, methyl methacrylate (MMA) and γ-methacryloxypropyltriethoxysilane (TEPM) are polymerized in proportion to form a copolymer, and the molecular formula of the copolymer is:

[0016] , where m and n are integers;

[0017] S11, dissolving the copolymer and polyvinylidene fluoride (PVdF) in a first solvent to form a first solution;

[0018] S12, providing a polyolefin porous membrane, and soaking the polyolefin porous membrane in a second solvent;

[0019] S13, coating the first solution on at least one side of the polyolefin porous membrane soaked with the second solvent;

[0020] S14, immersing the polyolefin porous membrane coated with the first solution into the third solvent to drill holes, thereby forming a gel polymer electrolyte prefabricated layer on the surface of the polyolefin porous membrane, the ...

Embodiment 1

[0046] Mix methyl methacrylate and γ-methacryloxypropyltriethoxysilane evenly at a molar ratio of 1:1, then add a certain amount of azobisisobutyronitrile (AIBN), at 80°C Stirring and polymerization to form a copolymer prepolymer; the copolymer prepolymer is dissolved in tetrahydrofuran to form a mixed solution of the copolymer prepolymer, and the mixed solution of the copolymer prepolymer is added to ethanol / water (volume ratio 1:1) mixed solvent for precipitation, and repeated three times to obtain polymethyl methacrylate-poly γ-methacryloxypropyltriethoxysilane copolymer precipitation; the copolymer precipitation and Polyvinylidene fluoride is mixed according to the mass ratio of 1:2, and dissolved in tetrahydrofuran to prepare the first solution with a concentration of about 10%; the first solution is scraped on the two surfaces of the Celgard-2325 diaphragm; the scraper is coated with The Celgard-2325 diaphragm of the first solution is immersed in a mixed solvent of ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com