Polydopamine surface-modified polyethersulfone nanofiber composite diaphragm, preparation method and application

A nanofiber film and nanofiber technology, applied in electrical components, electrochemical generators, circuits, etc., can solve the problems of unfavorable lithium ion migration, poor high temperature dimensional stability, poor electrolyte infiltration performance, etc., and achieve electrolyte infiltration Effect of improved properties, high porosity, good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of polyethersulfone nanofibrous membrane comprises the following steps: dissolving polyethersulfone (brand E3010, molecular weight 60,000) purchased from BASF in Germany in N,N-dimethylacetamide, magnetic stirring for 30min, and preparing The electrospinning solution with a mass fraction of 20% was filtered through a syringe filter with a specification of 25mm*0.45μm to remove impurities, and after standing for degassing for 30mim, a polyethersulfone nanofiber membrane was prepared by high-voltage electrospinning technology.

[0030] High-voltage electrospinning parameters: temperature 25°C, humidity 30%, needle diameter 1.5mm, voltage 20kv, injection pump injection rate 1.5mL / h, spinning time 2h, PET non-woven fabric as the receiving plate, receiving distance 15cm.

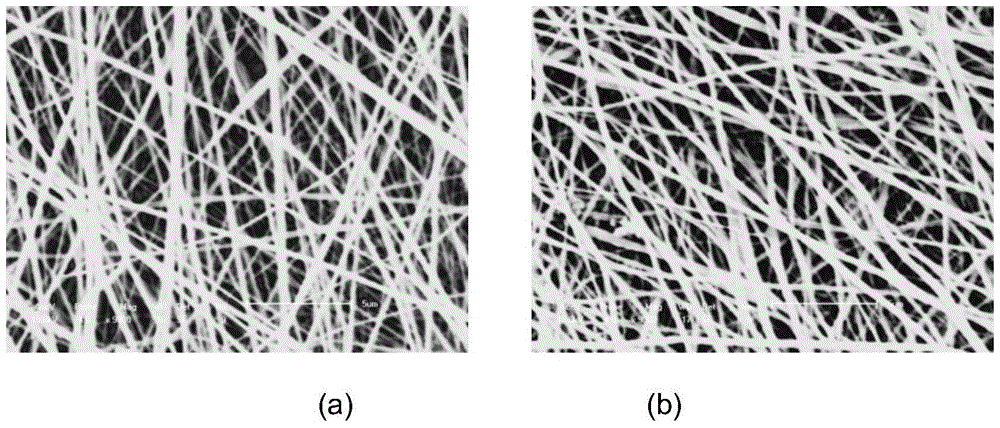

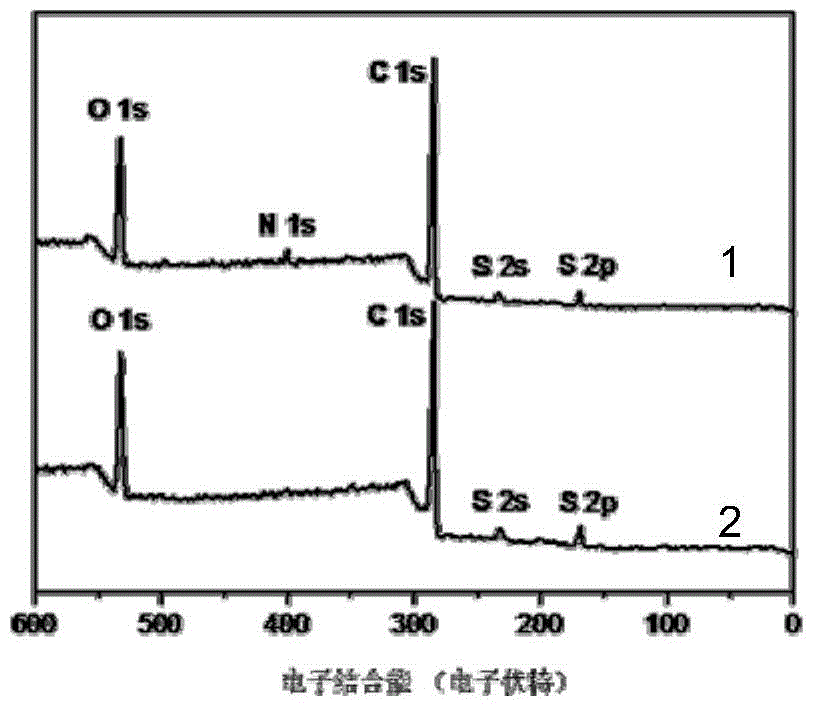

[0031] The thickness of the obtained polyethersulfone nanofiber membrane was 30 μm ( figure 1 (a)); fiber diameter between 200 ~ 400nm ( figure 2 (a)); n-butanol test porosity meth...

Embodiment 2

[0033] As in Example 1, an electrospinning solution with a mass fraction of 25% was prepared, and a polyethersulfone nanofiber membrane was prepared according to the same spinning conditions as in Example 1. Compared with the fiber membrane prepared in Example 1, as the concentration of the spinning solution increases, the fiber diameter increases, and the distribution of fiber diameter also increases accordingly. The fiber diameter is between 220 and 430nm; the porosity of the fiber membrane is about 82%; the fiber membrane tensile strength, elongation at break, contact angle between the fiber membrane and the electrolyte ethylene carbonate (EC), and thermal dimensions under high temperature conditions The stability was similar to the nanofibrous membrane obtained in Example 1.

Embodiment 3

[0035]As in Example 1, the spinning voltage was adjusted to 25 kv, and the polyethersulfone nanofiber membrane was prepared according to the same method and steps as in Example 1. The polyethersulfone nanofiber membrane was prepared according to the same spinning conditions as in Example 1. With the increase of the spinning voltage, the fiber diameter increases, and the porosity of the fiber membrane decreases, and the porosity is about 80%. Its electrolyte wettability and thermal dimensional stability are relatively close to those of the fiber membrane prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com