A flat-plate denitrification membrane for wastewater treatment and preparation method thereof

A waste water treatment, flat-plate technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve high energy consumption, easy fouling of treatment equipment, difficulty in large-scale application, etc. problems, to achieve good denitrification performance, easy to replace, and improve the effect of heat shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

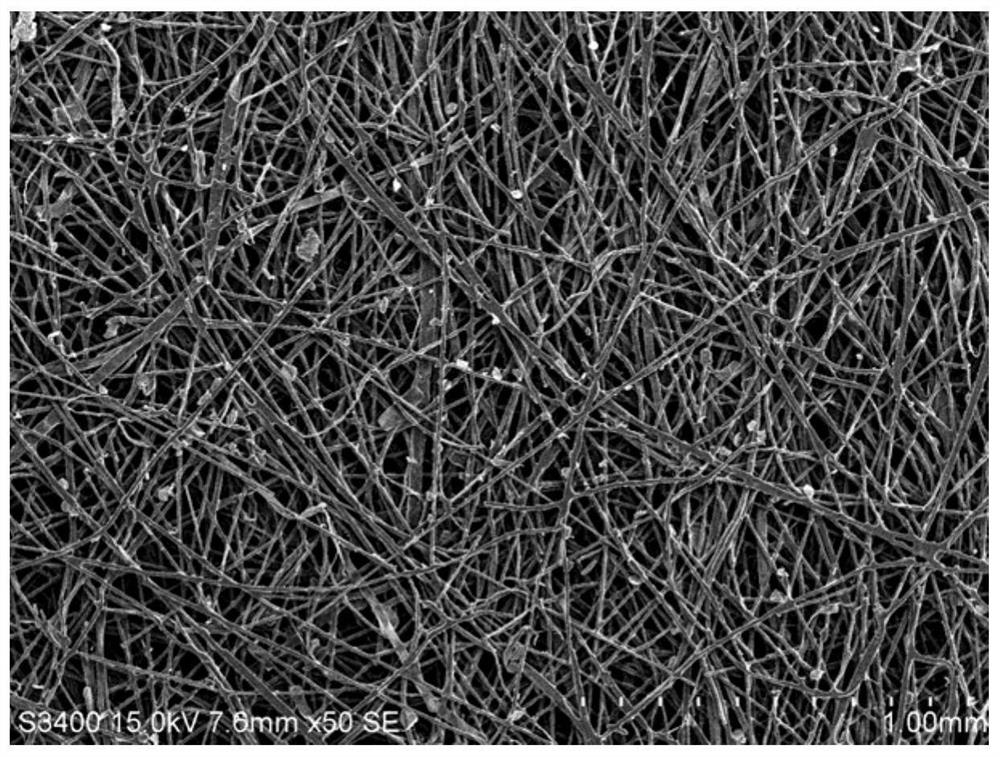

[0032] A preparation method of a flat-plate denitrification membrane for wastewater treatment of the present invention comprises the following steps:

[0033] Step 1: Use a wet papermaking process to make a mixed fiber slurry composed of polypropylene fibers, cellulose fibers and carbon fibers through a paper machine to form the non-woven substrate; among the process parameters of the non-woven substrate, the paper machine The sizing concentration is set to 0.01-0.5 wt %, the drying cylinder drying temperature is set to 90-120°C, and the soft calendering temperature is set to 100-130°C.

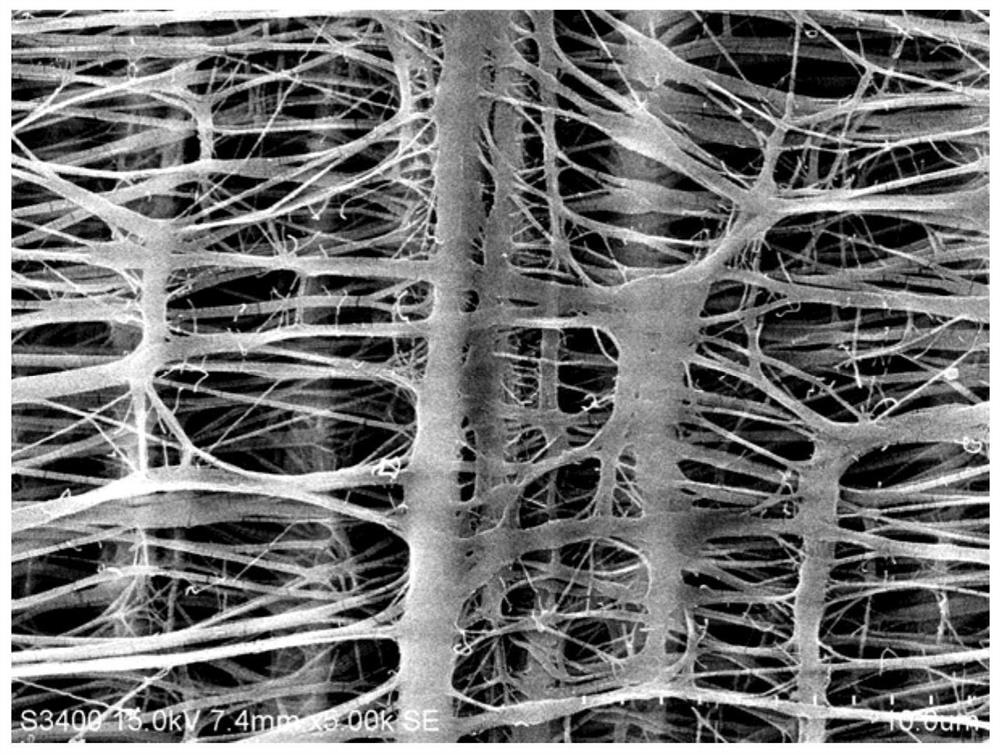

[0034] Step 2: The non-woven substrate and the expanded polytetrafluoroethylene film are pre-laminated on top of each other;

[0035] Step 3: Put it into a hot press for high temperature hot pressing. The hot pressing temperature is related to the melting point and hot pressing pressure of the selected polypropylene fibers; during high temperature hot pressing, the hot pressing temperature is...

Embodiment 1

[0039]A flat plate type denitrification membrane is composed of: a non-woven fabric base material layer and a gas permeable layer.

[0040] (1) The papermaking process and fiber formula of the non-woven substrate layer:

[0041] The invention provides the papermaking process parameter range of the non-woven base material: the sizing concentration of the paper machine is 0.01wt%, the drying temperature of the drying cylinder is 90°C, and the soft calendering temperature is 100°C.

[0042] The formula composition of the mixed fiber slurry: polypropylene fiber accounts for 60wt%, bamboo pulp fiber accounts for 30wt%, and carbon fiber accounts for 10wt%. The polypropylene fiber is a single-component polypropylene fiber, and the melting point of the polypropylene fiber is 150°C; the beating degree of the bamboo pulp fiber is 30°SR, preferably bleached bamboo pulp fiber; the temperature resistance of the carbon fiber is greater than 300°C.

[0043] (2) Selection of gas permeable la...

Embodiment 2

[0048] A flat plate type denitrification membrane is composed of: a non-woven fabric base material layer and a gas permeable layer.

[0049] (1) The papermaking process and fiber formulation of the non-woven substrate layer

[0050] The invention provides the papermaking process parameter range of the non-woven base material: the sizing concentration of the paper machine is 0.1 wt%, the drying temperature of the drying cylinder is 100°C, and the soft calendering temperature is 120°C.

[0051] The formula composition of the mixed fiber slurry: polypropylene fiber accounts for 70wt%, bamboo pulp fiber accounts for 15wt%, and carbon fiber accounts for 15wt%. The polypropylene fiber is a bicomponent polyethylene / polypropylene fiber, the melting point of the skin layer of the polypropylene fiber is 90°C, and the melting point of the fiber body is 170°C; the beating degree of the bamboo pulp fiber is 40°SR, preferably the bleached bamboo pulp fiber; The temperature resistance of ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com