Side draught type extractor hood

A range hood and side-suction technology, applied in the field of side-suction range hoods, can solve the problems of affecting the operating efficiency and service life of the push rod, reducing the service life of the push rod, increasing friction, etc., so as to avoid the smoke baffle Pause and jitter, prolong service life, improve the effect of using conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

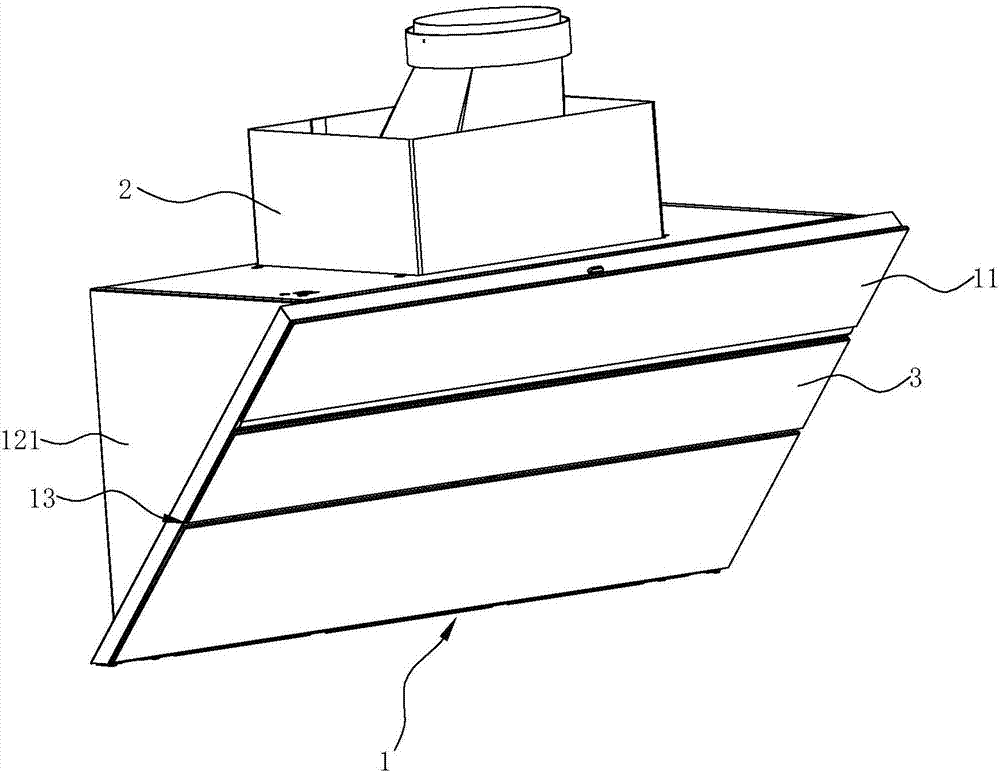

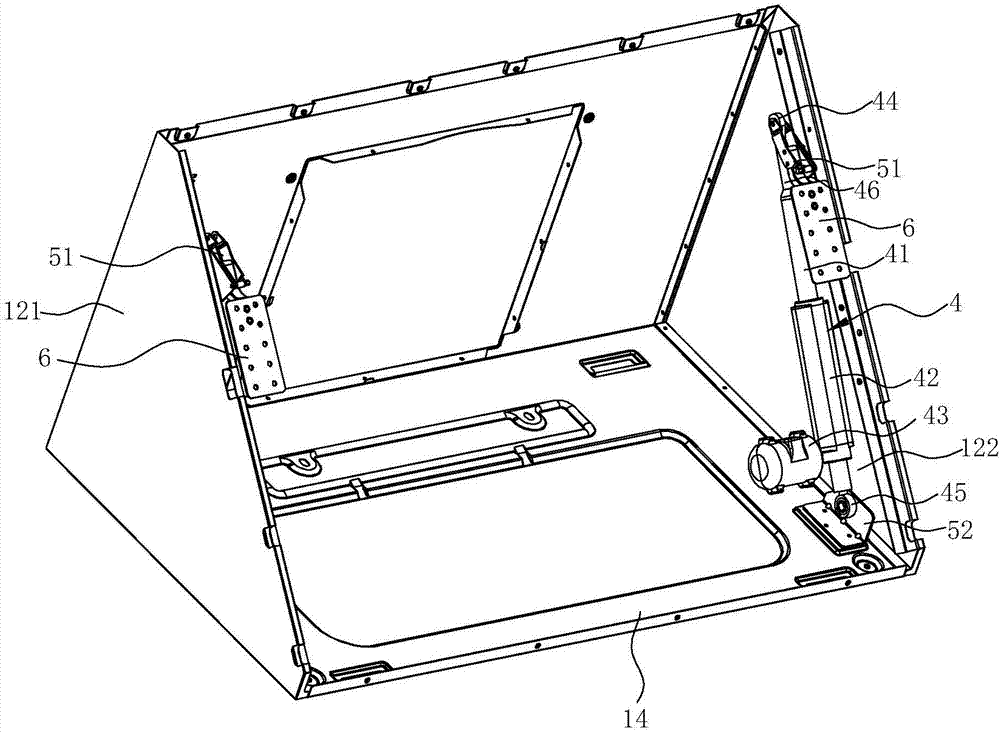

[0032] see figure 1 and figure 2 , a side suction range hood with an electric push rod mechanism, including a casing 1, a fan cover 2 and a fan system (not shown), the casing 1 is installed under the fan cover 2, and the fan system is installed under the fan cover 2 Inside and partly located on the back side of the casing 1.

[0033] The casing 1 includes a front panel 11 and a left side panel 121 and a right side panel 122 on both sides. The panel 11 is provided with an air inlet 13, and the smoke baffle 3 adapted to the size and shape of the air inlet 13 is hinged on the inlet. There are 13 outlets. When the range hood is turned on, the smoke baffle 3 is opened, and the fan system sucks the air in the casing 1 and discharges it to the public flue or outdoors through the fan cover 2, and a negative pressure is formed in the casing 1 so that the airflow entrained with oil fumes flows from the inlet The tuyere 13 enters the casing 1, and is then discharged to the public fl...

Embodiment 2

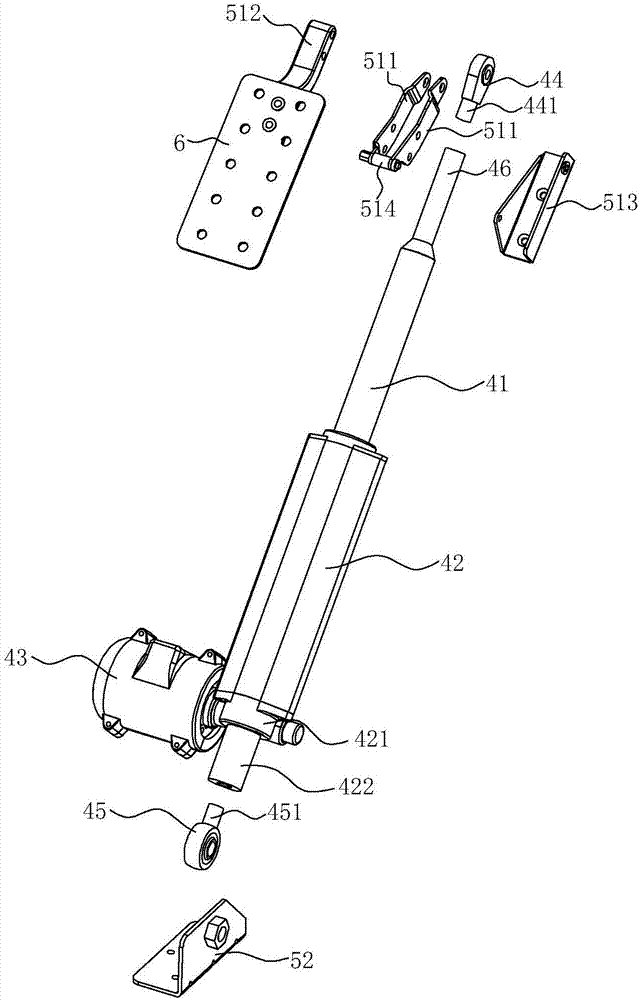

[0043] see Figure 4 with Figure 5 , In this embodiment, the difference from the first embodiment above is that the first bearing 44 is a rod end bearing, and the second bearing 45 is a bearing with a seat. The end cover 421 is provided with a shaft hole 423 , the second bearing 45 is connected with the end cover 421 through the shaft hole 423 , and the base 451 of the second bearing 45 is used for connecting with the casing 1 .

[0044] Similarly, the electric push rod mechanism 4 with double bearing structure can effectively reduce the gap error and avoid the stoppage and vibration of the smoke baffle 3 caused by the gap when the smoke baffle 3 changes direction under force when the smoke baffle 3 is moving. Phenomenon.

Embodiment 3

[0046] see Image 6 with Figure 7 , In this embodiment, the difference from the second embodiment above is that the first bearing 44 is a rod end joint bearing, and the second bearing 45 is a bearing with a seat.

[0047] The above-mentioned electric push rod mechanism 4 with double bearing structure enables the rotation of the smoke baffle 3 to be realized through bearings, which has the following advantages:

[0048] 1. The bearing has high precision and small gap, which can effectively reduce the gap error and avoid the pause and vibration of the smoke baffle 3 caused by the gap when the smoke baffle 3 is forced to change direction when the smoke baffle 3 is moving.

[0049] 2. The rod end joint bearing can rotate according to the bearing center, and has the characteristics of compensating the installation error when the push rod 41 and the push rod housing 42 are assembled. When the centers of the first bearing 44 and the second bearing 45 are slightly offset, it can pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com