Welding method for winding rotors and head combining sleeve

A welding method and winding rotor technology are applied in welding equipment, metal processing equipment, manufacturing tools, etc., which can solve the problems of large overall thickness, waste of solder, and damage to coil insulation, and achieve reduced rotor failure, good process reliability, and The effect of short welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0018] The welding method of the wound rotor joint head includes the following process steps:

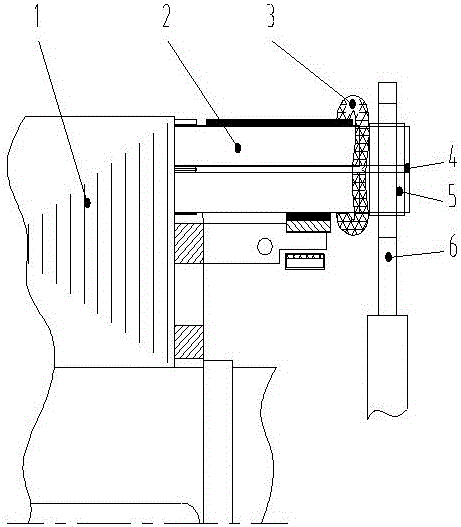

[0019] Step 1, such as figure 1 As shown, after the rotor coil 2 of the motor is embedded in the rotor core 1 and bent and reshaped, the end of the rotor coil 2 of the motor is covered with a parallel cap 5, and a parallel wedge 4 is embedded in the middle of the two rotor coils 2 of the motor. Tighten the headgear 5; then hoist the rotor to the welding workbench and place it horizontally;

[0020] Step two, such as figure 1 As shown, a circle of asbestos rope 3 soaked in water is wrapped around the insulation of the motor rotor coil 2 and the adjacent part of the headgear 5 as the welding protection of the motor rotor coil 2, so as to prevent the insulation of the motor rotor coil 2 from burning out;

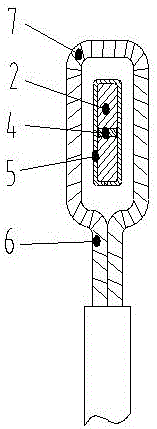

[0021] Step 3: Wrap one or two layers of glass ribbon 7 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com