Lithium ion battery anode plate, preparation method thereof and lithium ion battery using lithium ion battery anode plate

A lithium-ion battery and positive electrode technology, which is applied in the direction of battery electrodes, electrode carriers/collectors, non-aqueous electrolyte battery electrodes, etc., can solve problems affecting the industrialization of lithium-ion batteries, safety accidents, and difficult to meet, and achieve improved electrical conductivity properties, suppress dendrites, and have good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] see figure 2 As shown, it is a schematic diagram of Example 1 of the preparation method of lithium-ion battery positive electrode sheet of the present invention, which includes the following steps:

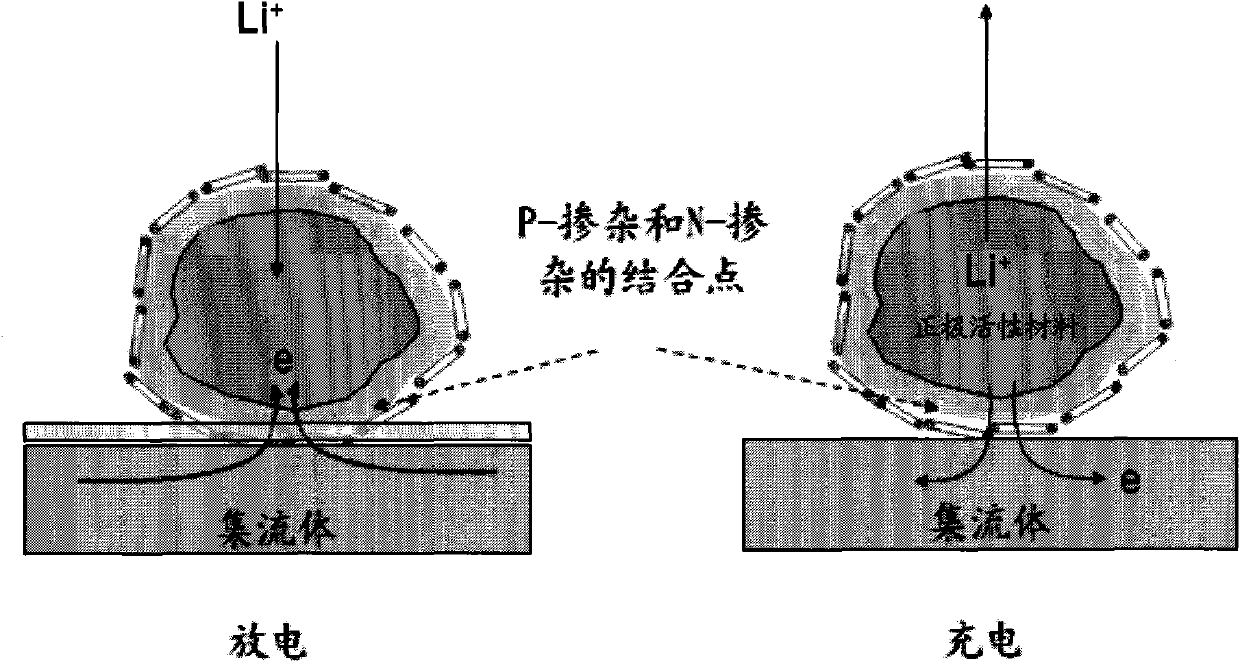

[0034] In the first step, the cathode active material LiCoO 2 , N-type doped carbon nanotubes (N-doping CNT) and binder polyvinylidene fluoride (PVDF) are uniformly dissolved in the solvent N-methylpyrrolidone (NMP) at a weight ratio of 98.5:1:0.5 and stirred evenly; After evaporating the solvent NMP, N-doping CNT-coated LiCoO was obtained by crushing and grinding 2 powder.

[0035] In the second step, N-doping CNT-coated LiCoO 2 , P-type doped carbon nanotubes (P-dopingCNT), and binder styrene-butadiene rubber (SBR) are dissolved in solvent water at a weight ratio of 98.5:1:0.5 and stirred evenly; after evaporating solvent water, they are obtained by crushing and grinding LiCoO coated with P-Doping CNT and N-doping CNT 2 powder.

[0036] In the third step, LiCoO coa...

Embodiment 2

[0039] see image 3 Shown is a schematic diagram of Example 2 of the preparation method of the lithium ion battery positive electrode sheet of the present invention, which includes the following steps:

[0040] In the first step, the cathode active material LiCoO 2 , N-doping CNT and binder PVDF are uniformly dissolved in the solvent NMP at a weight ratio of 98.5:1:0.5 and stirred evenly; after the solvent PVDF is evaporated, LiCoO coated with N-doping CNT is obtained by crushing and grinding 2 powder.

[0041] In the second step, P-doping CNT and binder PVDF are dissolved in solvent water at a weight ratio of 2:1, and stirred evenly to obtain a slurry; the slurry is evenly coated on the Al alloy positive electrode current collector to make P-dopingCNT Coated Al alloy cathode current collector.

[0042] In the third step, N-doping CNT-coated LiCoO 2 1. The binder styrene-butadiene rubber (SBR) is dissolved in solvent water at a weight ratio of 98:2, and stirred evenly to o...

Embodiment 3

[0045] see Figure 4 Shown is a schematic diagram of Example 3 of the preparation method of the lithium ion battery positive electrode sheet of the present invention, which includes the following steps:

[0046] The first step: the cathode active material LiCoO 2 , N-doping CNT and binder PVDF are uniformly dissolved in the solvent NMP at a weight ratio of 98.5:1:0.5 and stirred evenly. After the solvent NMP is evaporated, LiCoO coated with N-doping CNT is obtained by crushing and grinding. 2 powder.

[0047] In the second step, the P-doping CNT and the binder PVDF are dissolved in the solvent NMP in a weight ratio of 2:1, and the slurry is evenly stirred to obtain a slurry; the slurry is evenly coated on the polyester film Mylar to obtain the P-doping CNT Coated thin film, and this thin film is used as positive electrode current collector.

[0048] In the third step, N-doping CNT-coated LiCoO 2 1. The binder SBR is dissolved in solvent water at a weight ratio of 98.5:1.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com