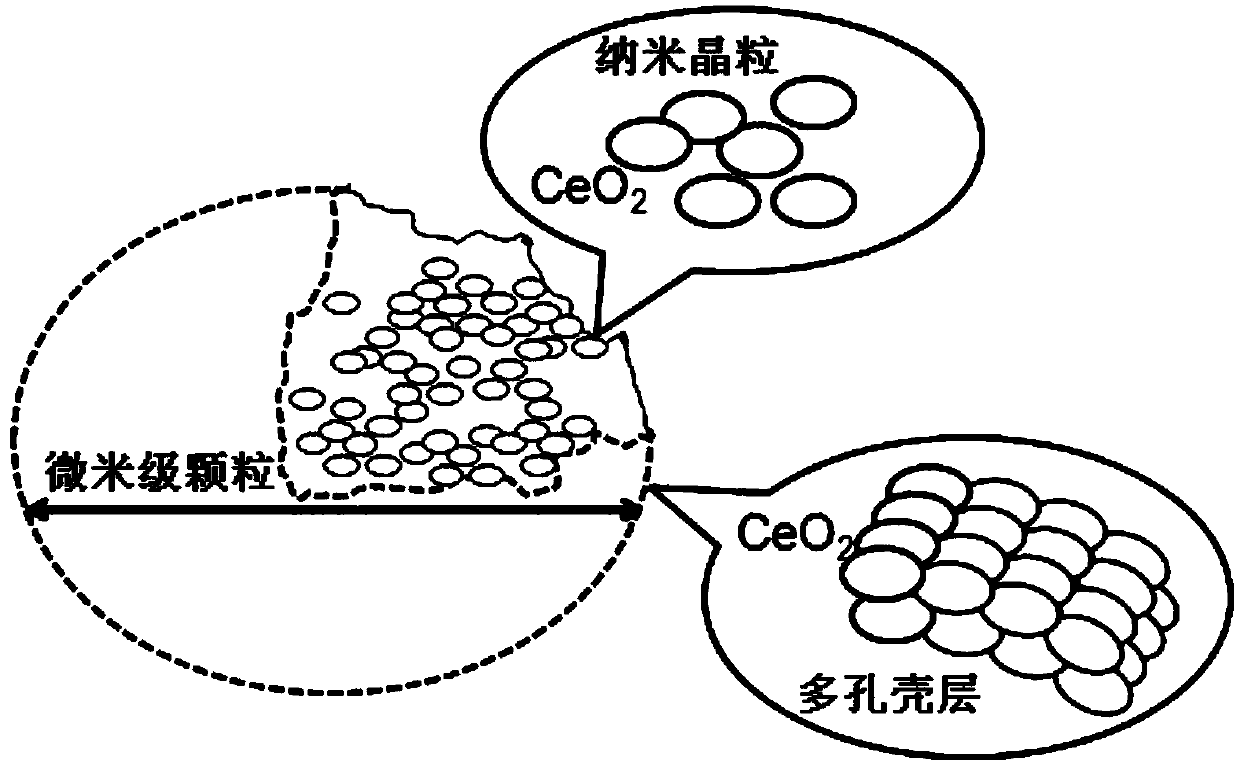

A kind of micron cerium oxide particles with multi-core co-shell structure and preparation method thereof

A technology of nano-cerium oxide and cerium oxide, which is applied in chemical instruments and methods, catalyst activation/preparation, cerium oxide/cerium hydroxide, etc., can solve problems such as limiting the application of cerium oxide materials, poor sulfur resistance, and catalyst deactivation. Achieve the effects of good hydrothermal stability, high mechanical strength and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

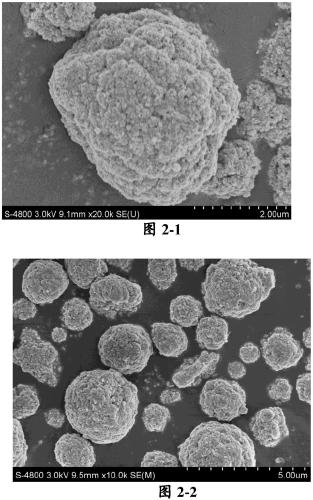

[0060] Micron cerium oxide particles C1 with a multi-core co-shell structure were prepared by the following steps:

[0061] A. Make the cerium salt solution react with the precipitating agent to generate a suspension, adjust the pH value of the suspension, pass air into the generated suspension to oxidize, and obtain a liquid phase dispersion system of the nano-cerium oxide precursor; optionally , adding an organic additive to the liquid phase dispersion system of the nano-cerium oxide precursor;

[0062] B. Spray-drying and roasting the liquid phase dispersion system of the nano-cerium oxide precursor to obtain the embryo body of nano-cerium oxide crystal grain nuclei aggregates;

[0063] C. Dispersing the nano-cerium oxide grain nucleus aggregate embryo body into a solvent to obtain a suspension and adding a cerium salt solution and a precipitant to the suspension to deposit around the nano-cerium oxide grain nucleus aggregate Encapsulation reaction to obtain a second suspe...

Embodiment 5-8

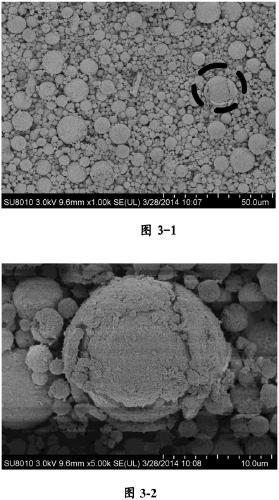

[0070] Micron cerium oxide particles C2 with multi-core co-shell structure are prepared by the following steps:

[0071] A. make the cerium salt solution react with the precipitating agent to generate a suspension, adjust the pH value of the suspension, pass air into the generated suspension to oxidize, and obtain the liquid phase dispersion system of the nano-cerium oxide precursor;

[0072] B. adding organic auxiliary agent and cerium salt solution in the liquid phase dispersion system of described nanometer cerium oxide precursor, obtains the uniformly dispersed liquid phase dispersion system;

[0073] C. Spray drying and calcining the homogeneously dispersed liquid phase dispersion system to obtain micron cerium oxide particles with a multi-core co-shell structure. The micron cerium oxide particles with multi-core co-shell structure prepared by this method were named C2.

[0074] The specific experimental conditions are shown in Table 2:

[0075] Table 2: Preparation con...

Embodiment 9-12

[0078] Micron cerium oxide particles C3 with a multi-core co-shell structure are prepared by the following steps:

[0079] A. make cerium salt solution and precipitating agent react to generate suspension, wherein said cerium salt solution and / or precipitating agent contain organic auxiliary agent, and wherein said cerium salt is stoichiometric excess relative to precipitating agent; Adjust The pH value of the suspension is oxidized by introducing air into the generated suspension to obtain a liquid phase dispersion system of the nano-cerium oxide precursor;

[0080] B. Spray-drying and calcining the liquid-phase dispersion system of the nano-cerium oxide precursor to obtain micro-cerium oxide particles with a multi-core co-shell structure. The micron cerium oxide particles with multi-core co-shell structure prepared by this method were named C3.

[0081] The specific experimental conditions are shown in Table 3:

[0082] Table 3: Preparation conditions of Examples 9-12

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com