Slot-type embedded part and application node structure of same

A technology of embedded parts and grooves, which is applied to building components, building structures, walls, etc., can solve the problems of large volume of embedded parts, difficult to embed, and difficult to correct the deviation of the embedded position, etc. The effect of convenient construction and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

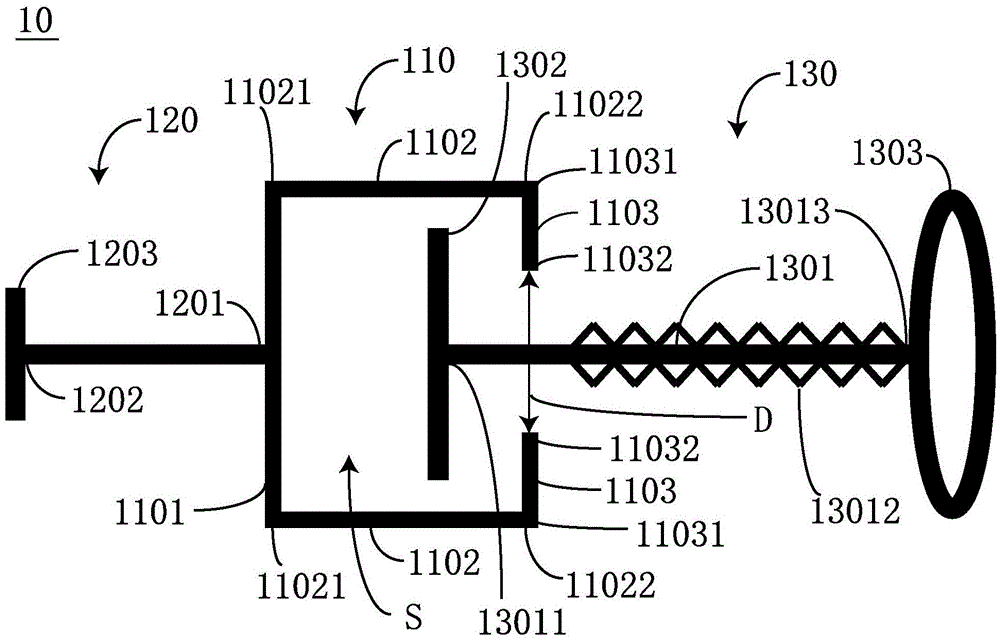

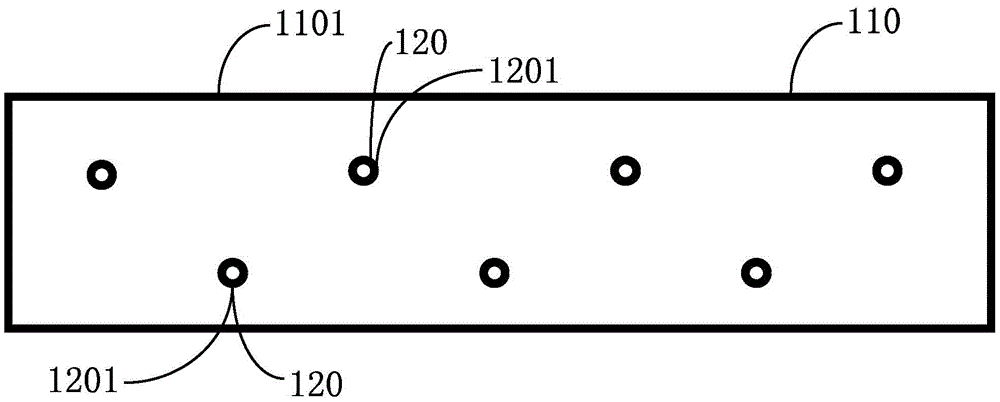

[0044] In order to solve the technical problems that the embedded parts at the present stage are bulky, difficult to embed, and difficult to correct the deviated embedded position. Such as Figure 1-3Shown are the structural schematic diagrams of the trough embedded parts 10 according to the first embodiment of the present invention. The trough embedded parts 10 include a trough connection part 110 , a plurality of anchor bars 120 and a plurality of T-bolts 130 .

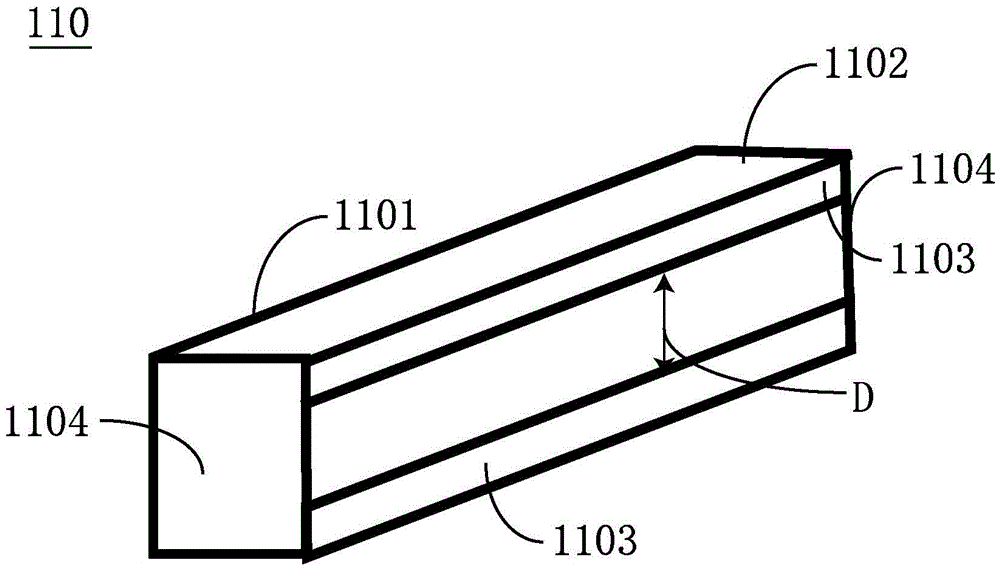

[0045] The trough connection part 110 includes a waist body 1101, two supporting legs 1102 and two barrier parts 1103, the first ends 11021 of the two supporting legs 1102 are respectively connected to the top and bottom of the waist body 1101, and the two barrier parts The first ends 11031 of the part 1103 are respectively connected to the second ends 11022 of the two supporting legs 1102, and the second ends 11032 of the two blocking parts 1103 are respectively bent toward the middle of the waist 1101 and separate...

Embodiment 2

[0055] In order to solve the technical problems that the embedded parts at the present stage are bulky, difficult to embed, and difficult to correct the deviated embedded position. Such as Figure 4-5 As shown, they are schematic diagrams of the application node structure of a trough embedded part of the present invention. The application node of the trough embedded part includes a trough embedded part 10, a concrete member 20 and an external structural connecting plate connecting plate.

[0056] The trough embedded part 10 includes a trough connection part 110 , a plurality of anchor tendons 120 and a plurality of T-bolts 130 . The trough embedded part 110 includes a waist 1101, two supporting legs 1102 and two partitions 1103, the first ends 11021 of the two supporting legs 1102 are respectively connected to the top and bottom of the waist 1101, and the two partitions The first ends 11031 of the blocking parts 1103 are respectively connected to the second ends 11022 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com