Liquid crystal polyurethane urea material with cholesteric side chains and preparation method of liquid crystal polyurethane urea

A technology of polyurethane urea and cholesterol, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems that the oxidation rate of PU film cannot be guaranteed, the surface mechanism of materials will be damaged, and the mechanical properties of polymers will be damaged, so as to improve blood compatibility Good blood compatibility and biocompatibility, the effect of improving blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

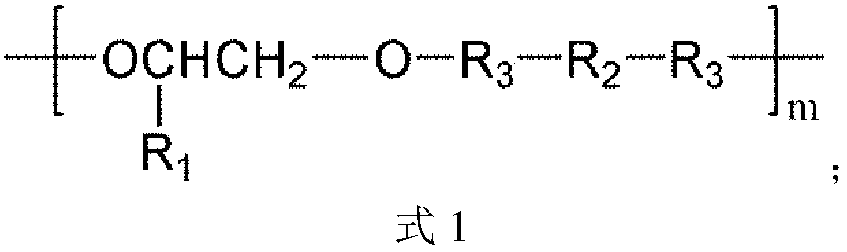

[0068] Under the protection of dry nitrogen, 10.94g (15mmol) single-ended dihydroxy liquid crystal monomer (DAP) and 5.0g (5mmol) polyethylene glycol (PEG, M n =1000) were mixed, N,N-dimethylformamide (DMF) was added to dissolve (0.5g / mL), the temperature of the reaction system was raised to 80°C, and a DMF solution (1.0g / mL) of HBH (20.2mmol) was added dropwise, After the dropwise addition, keep the temperature and continue the reaction for 4.0 h, lower to room temperature, then add DMF to prepare a solution with a concentration of 8 g / 100 ml, settle with 8 times the volume of glacial ether, and dry the obtained solid under vacuum at 35°C.

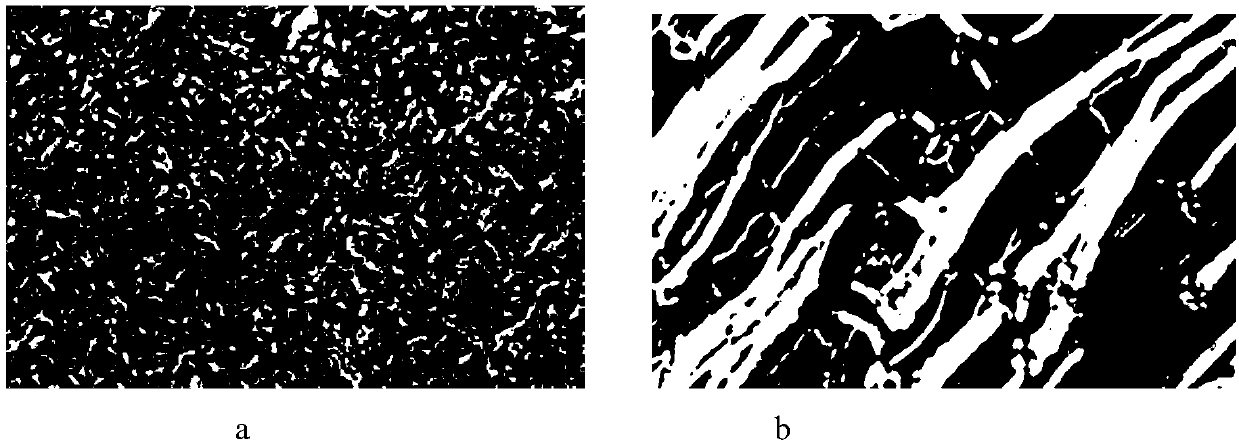

[0069] Dissolve the solid in tetrahydrofuran, an organic solvent, to a concentration of 6.0g / 100mL, volatilize it in a polytetrafluoroethylene mold at 25°C under normal pressure for 80 hours, remove the film from the mold, and dry it in vacuum at room temperature for 1 day to obtain side Chain type liquid crystal polyurethane urea film ma...

Embodiment 2

[0071] Under the protection of dry nitrogen, 21.87g (30mmol) terminal dihydroxy liquid crystal monomer (DAP) and 5.0g (5mmol) polyethylene glycol (PEG, M n =1000) were mixed, N,N-dimethylformamide (DMF) was added to dissolve (0.4g / mL), the temperature of the reaction system was raised to 85°C, and a DMF solution (0.8g / mL) of HBH (35.7mmol) was added dropwise, After the dropwise addition, keep the temperature and continue the reaction for 3.5 hours, lower to room temperature, then add DMF to prepare a solution with a concentration of 6g / 100ml, settle with 8 times the volume of glacial ether, and dry the obtained solid under vacuum at 45°C.

[0072] Dissolve the solid in the organic solvent tetrahydrofuran to a concentration of 5.5g / 100mL, volatilize it in a polytetrafluoroethylene mold at 15°C under normal pressure for 75 hours, remove the film from the mold, and dry it in vacuum at room temperature for 1 day to obtain the side Chain type liquid crystal polyurethane urea film m...

Embodiment 3

[0074] Under the protection of dry nitrogen, 7.29g (10mmol) terminal dihydroxy liquid crystal monomer (DAP) and 15.0g (5mmol) polyethylene glycol (PEG, M n =3000) were mixed, N,N-dimethylformamide (DMF) was added to dissolve (0.6g / mL), the temperature of the reaction system was raised to 75°C, and a DMF solution (0.6g / mL) of HBH (26.25mmol) was added dropwise, After the dropwise addition, keep the temperature and continue the reaction for 4.5 h, lower to room temperature, then add DMF to prepare a solution with a concentration of 9 g / 100 ml, settle with 8 times the volume of glacial ether, and dry the obtained solid under vacuum at 40°C.

[0075]Dissolve the solid in the organic solvent tetrahydrofuran to a concentration of 5.5g / 100mL, volatilize it in a polytetrafluoroethylene mold at 25°C under normal pressure for 70 hours, remove the film from the mold, and dry it in vacuum at room temperature for 1 day to obtain the side Chain type liquid crystal polyurethane film material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com