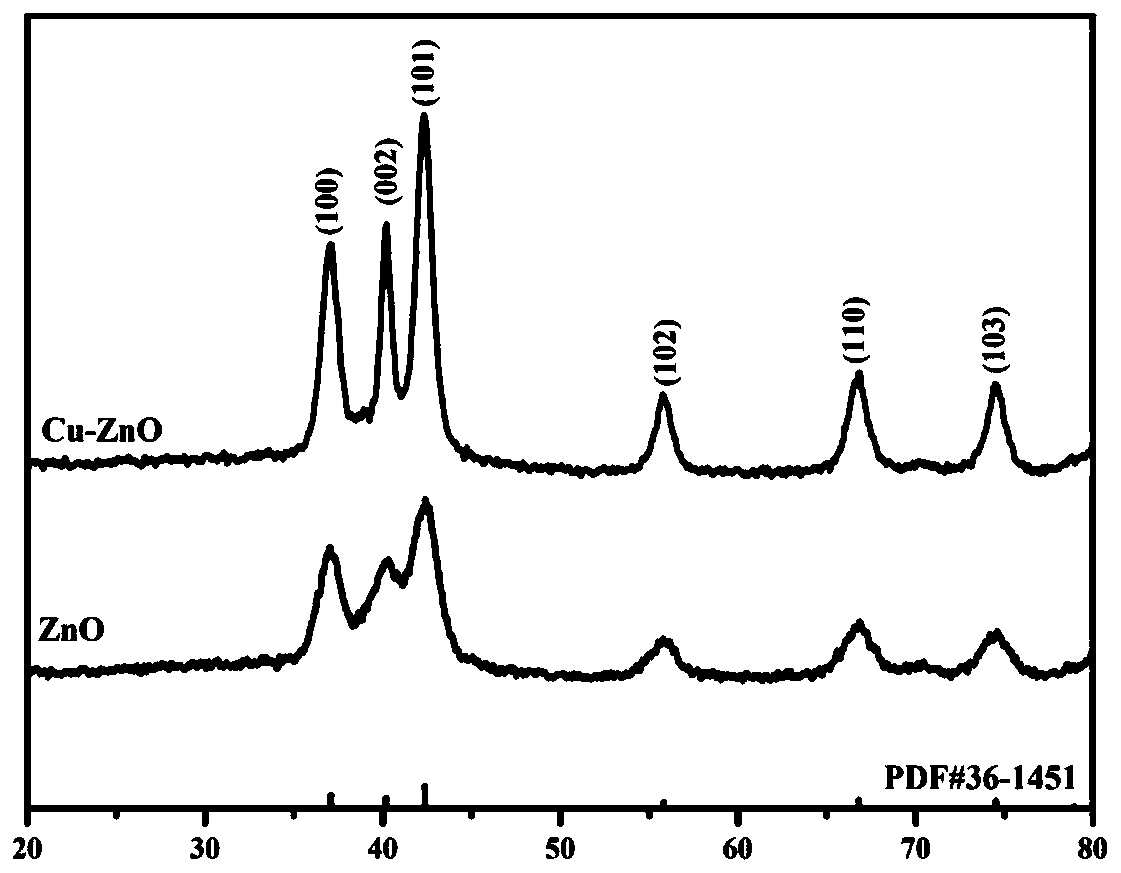

Copper-doped zinc oxide quantum dot nano antibacterial agent and preparation method thereof

A technology of nano antibacterial agent and zinc oxide, applied in the field of copper doped zinc oxide quantum dot nano antibacterial agent and its preparation, can solve the problem of no antibacterial effect found, and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A preparation method of Cu-doped ZnO quantum dot nano antibacterial agent, comprising the following steps:

[0050] Weigh 0.5-2.0g zinc source and the copper source according to the molar ratio of the zinc in the zinc source to the copper in the copper source is 1:0.003-0.01 and disperse in 80-120mL organic solvent, after stirring evenly , poured into a three-necked flask, heated in a water bath at 60-90°C, and kept warm for 0.5-2h until the solution was clear and transparent, then continued to stir at 20-30°C and stood by to obtain a mixed precursor solution of zinc and copper; 0.15-1g Add the alkali source into 80-120mL organic solvent, stir magnetically at 20-30°C for 20-40min, then add the obtained alkali solution dropwise to the mixed precursor solution of zinc and copper prepared in the previous stage, after mixing evenly, magnetically stir at 20-30°C Stir for 20-40min, add 50-100mL precipitant after the reaction until the solution turns milky white, stir magnetic...

Embodiment 1

[0056] A preparation method of copper-doped zinc oxide quantum dot nano antibacterial agent, comprising the following steps:

[0057] Weigh 0.768g of zinc acetate dihydrate and 4.89mg of copper acetate monohydrate and disperse them in 100mL of absolute ethanol. After stirring evenly, pour them into a three-necked flask and heat the reaction in a water bath at 80°C for 0.5h until the solution is clear and transparent. Continue to stir and wait for use to obtain the zinc and copper mixed precursor solution; add 0.15g lithium hydroxide to 100mL ethanol solution, stir magnetically at 20°C for 30 minutes, then add the obtained alkali solution dropwise to the zinc and copper mixed precursor solution prepared earlier. In the precursor solution, after mixing evenly, stir magnetically at 20°C for 30min, add 80mL deionized water until the solution turns milky white after the reaction, stir magnetically at 20°C for 10min, let stand, wash, and centrifuge at 6000rpm for 30min to obtain copp...

Embodiment 2

[0059] A preparation method of copper-doped zinc oxide quantum dot nano antibacterial agent, comprising the following steps:

[0060] Weigh 1.1g of zinc nitrate hexahydrate and 6.98mg of copper nitrate trihydrate and disperse them in 100mL of absolute ethanol. After stirring evenly, pour them into a three-necked flask, heat and react in a water bath at 80°C for 1h until the solution is clear and transparent, and then continue at 23°C. Stir and set aside to obtain the zinc and copper mixed precursor solution; add 0.3g lithium hydroxide to 100mL ethanol solution, stir magnetically at 23°C for 30min, then add the obtained alkali solution dropwise to the zinc and copper mixed precursor prepared earlier After mixing evenly, stir magnetically at 23°C for 30min. After the reaction, add 100mL of deionized water until the solution turns milky white, stir magnetically at 23°C for 10min, let stand, wash, and centrifuge at 8000rpm for 18min to obtain copper (Cu). Doped with zinc oxide qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com