Preparation method for low-temperature fixing chemical ink powder resin and method for preparing ink powders

A low-temperature, resin-based technology, applied in optics, developers, instruments, etc., can solve the problems of unfavorable environmental storage of toner, affecting the shape of toner, failure of additive particles, etc., and achieve good printing quality, difficult embedding, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Configuration 820.0g mass fraction 5% polyoxyethylene (10) carboxylic acid alkyl ether aqueous solution, and the mixing of 840.0g styrene, 330.0g n-butyl acrylate, 30.0g hydroxyethyl methacrylate and 6.0g methacrylic acid Monomer (total 1206.0 g).

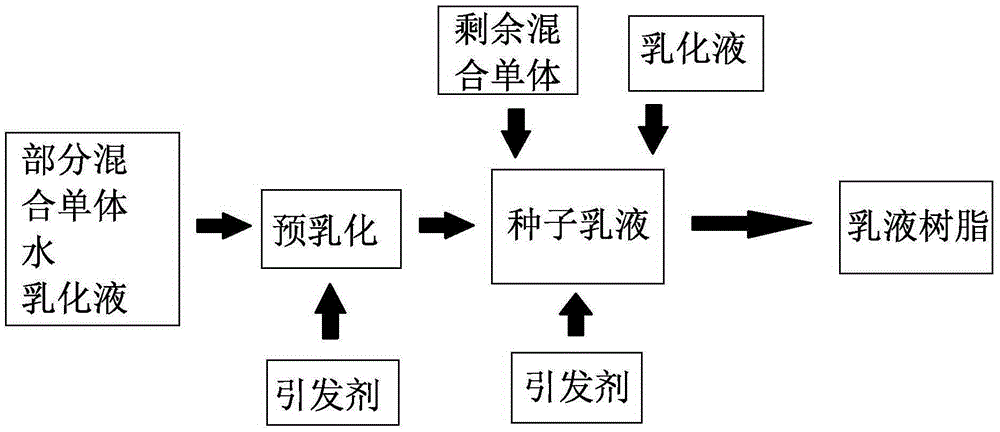

[0036] In a 5000ml four-necked reaction flask equipped with a stirring motor, reflux condenser, thermometer and peristaltic pump, add 1500ml deionized water, 300.0g polyoxyethylene (10) carboxylic acid alkyl ether aqueous solution (5% mass fraction), add 120.0 g mixed monomers, started stirring, adjusted the pH value to 8.2-8.6 with ammonia water, heated the mixture to 82°C, evenly added 40.0g of ammonium persulfate aqueous solution with a concentration of 3.5%, reacted for 60min, and kept the system at 85°C to prepare Seed lotion. Then 1086.0g of remaining mixed monomers, 520.0g of polyoxyethylene (10) aqueous solution of carboxylic acid alkyl ether (5% by mass fraction), 200.0g of ammonium persulfate aqueous solution with...

Embodiment 2

[0038] Configuration 820.0g mass fraction 5% polyoxyethylene (10) carboxylic acid alkyl ether aqueous solution, and 916.0g styrene, 248.0g n-butyl acrylate, 36.0g hydroxyethyl methacrylate, 2.0g methacrylic acid and 12.0 g Mixed monomers of n-dodecanethiol (total 1214.0 g).

[0039] In a 5000ml four-necked reaction flask equipped with a stirring motor, reflux condenser, thermometer and peristaltic pump, add 1500ml deionized water, 300.0g polyoxyethylene (10) carboxylic acid alkyl ether aqueous solution (5% mass fraction), add 120.0 g mixed monomers, started stirring, adjusted the pH value to 8.2-8.6 with ammonia water, heated the mixture to 82°C, evenly added 40.0g of ammonium persulfate aqueous solution with a concentration of 3.5%, reacted for 60min, and kept the system at 85°C to prepare Seed lotion. Then 1094.0g of remaining mixed monomers, 520.0g of polyoxyethylene (10) carboxylic acid alkyl ether aqueous solution (5% by mass fraction) 520.0g, and 200.0g of ammonium pers...

Embodiment 3

[0041] Configure 820.0g mass fraction of 5% polyoxyethylene (10) carboxylic acid alkyl ether aqueous solution, and 720.0g styrene, 140.0g n-butyl acrylate, 300.0g n-butyl methacrylate, 40.0g hydroxyethyl methacrylate A mixed monomer of ester, 6.0g methacrylic acid and 12.0g n-dodecanethiol (total 1218.0g).

[0042] In a 5000ml four-necked reaction flask equipped with a stirring motor, reflux condenser, thermometer and peristaltic pump, add 1500ml deionized water, 300.0g polyoxyethylene (10) carboxylic acid alkyl ether aqueous solution (5% mass fraction), add 120.0 g mixed monomers, started stirring, adjusted the pH value to 8.2-8.6 with ammonia water, heated the mixture to 82°C, evenly added 40.0g of ammonium persulfate aqueous solution with a concentration of 3.5%, reacted for 60min, and kept the system at 85°C to prepare Seed lotion. Then 1098.0g of the remaining mixed monomers, 520.0g of polyoxyethylene (10) aqueous solution of carboxylic acid alkyl ether (5% by mass fract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com