Abrasive for grinding and polishing of tellurium-zinc-cadmium soft and crispy wafers

An abrasive, cadmium zinc telluride technology, applied in the field of abrasives, can solve problems affecting the application of polishing fluid, polishing fluid instability, failure, etc., to achieve the effect of fast material removal rate, shortened processing time, and low damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

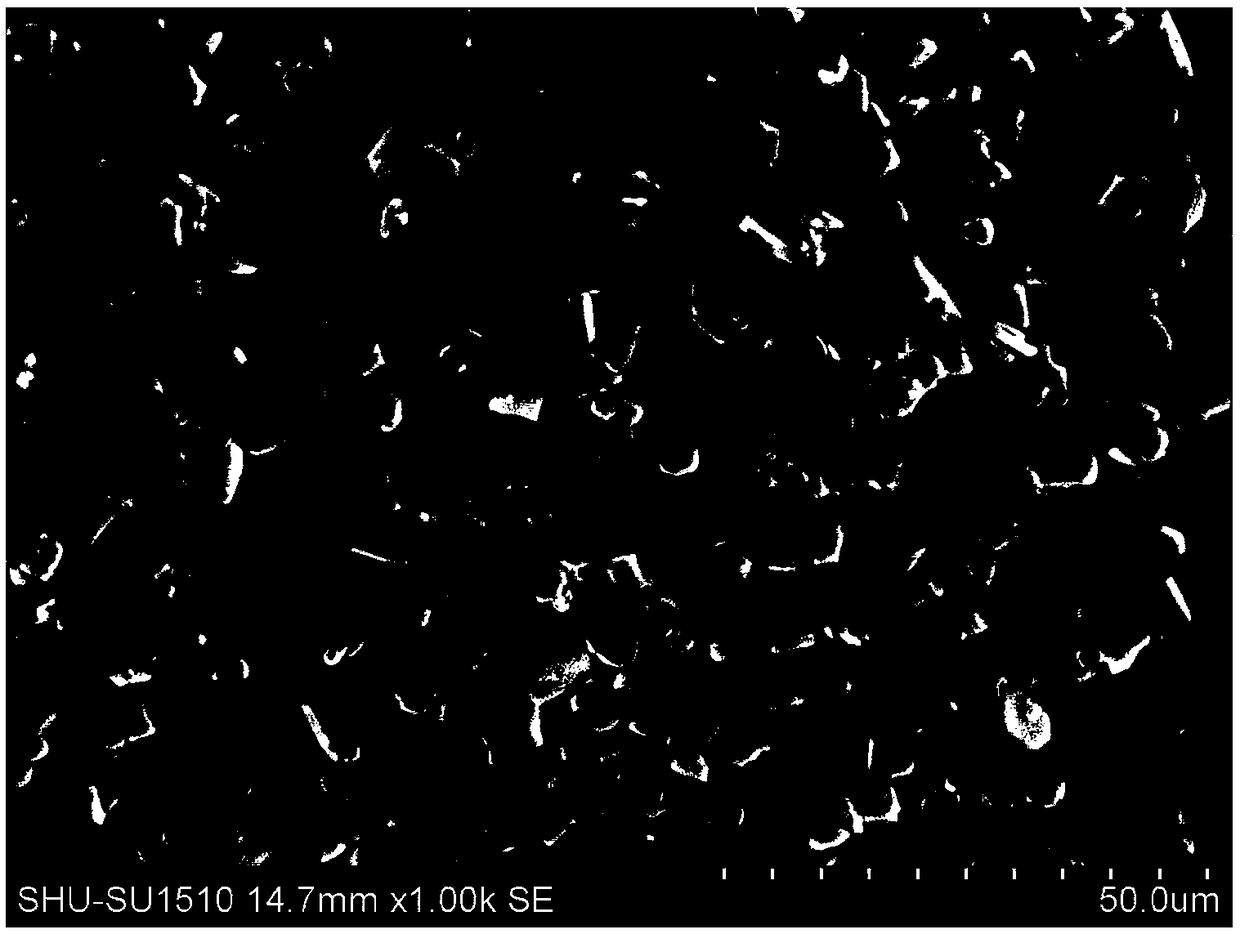

[0026] Choose 1# regular sheet-like abrasive, the shape of the particles see figure 1 . The main experimental steps are:

[0027] (1) Preparation of grinding liquid: using deionized water as a solvent to prepare grinding liquid, adjusting the pH of the suspension to 9, adding ammonium polyacrylate dispersant with a mass fraction of 0.8%, and stirring for 5 minutes before use.

[0028] (2) Wafer grinding: use the Logitech-PM5 precision polishing machine imported from the UK to mechanically grind the wafer, using a 4-inch grinding head, a flat glass experimental grinding disc, the grinding disc speed is 10RPM, the grinding pressure is 19N, the grinding time is 5min, and the grinding liquid The flow rate is appropriate to ensure that the liquid fully wets the grinding disc.

[0029] (3) Observation of wafer surface morphology: OLYMPUS-BX51 optical microscope was used to observe the macroscopic morphology of wafer surface after grinding.

[0030] The macroscopic morphology of t...

Embodiment 2

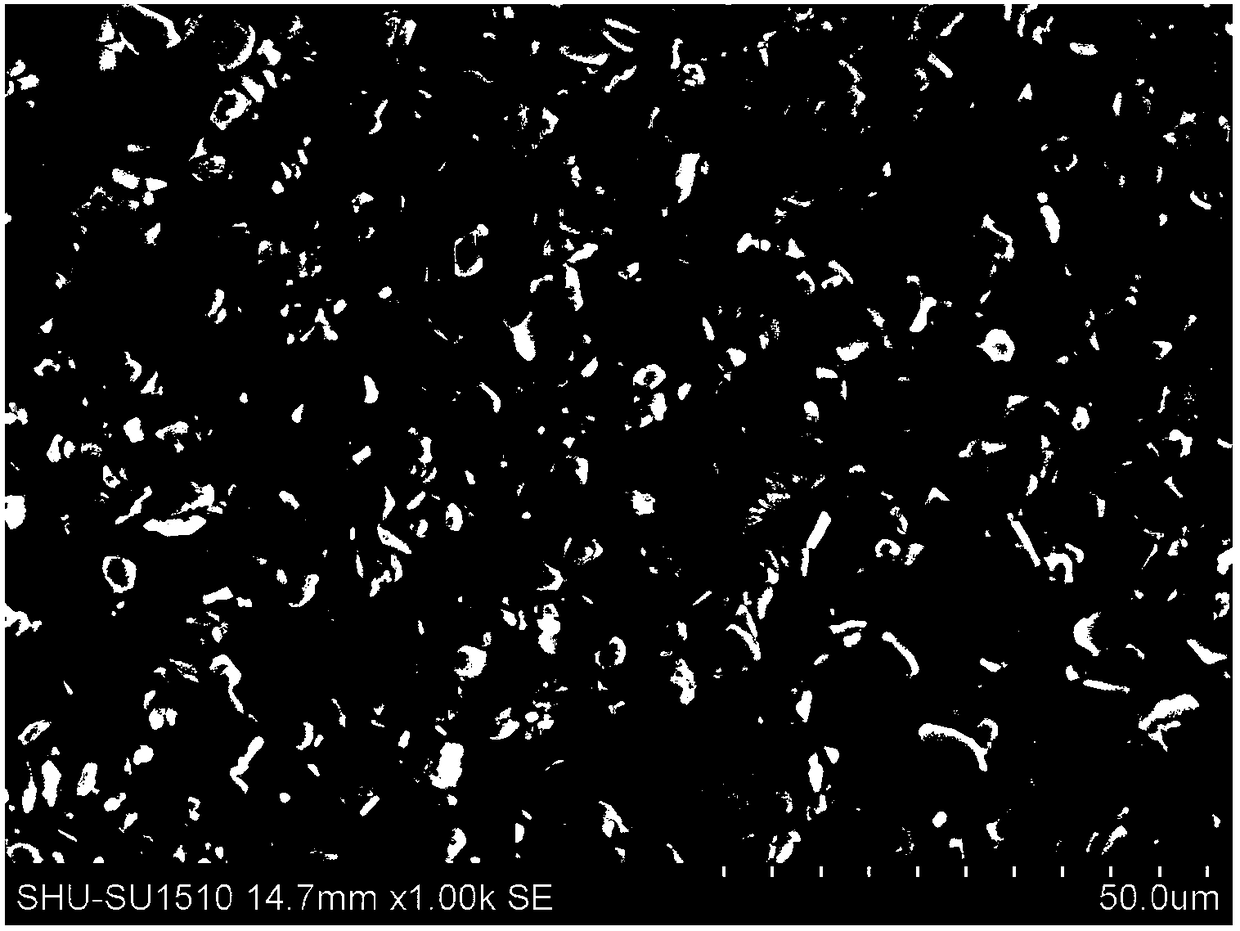

[0032] Use 2# regular thin plate abrasive, particle size D 50 It is 4.94μm, and its particle shape is shown in image 3 . The main experimental steps are:

[0033] (1) Preparation of grinding liquid: prepare grinding liquid with deionized water as solvent, adjust the pH of the suspension to 4, add polyethylene glycol dispersant with a mass fraction of 1%, and stir for 5 minutes before use.

[0034] (2) Wafer grinding: use the Logitech-PM5 precision polishing machine imported from the UK to mechanically grind the wafer, using a 4-inch grinding head, a flat glass experimental grinding disc, the grinding disc speed is 10RPM, the grinding pressure is 19N, the grinding time is 5min, and the grinding liquid The flow rate is appropriate to ensure that the liquid fully wets the grinding disc.

[0035] (3) Observation of wafer surface morphology: OLYMPUS-BX51 optical microscope was used to observe the macroscopic morphology of wafer surface after grinding.

[0036] The macroscopic ...

Embodiment 3

[0038] Choose 3# regular thick plate abrasive, the particle morphology is shown in Figure 5 . The main experimental steps are:

[0039] (1) Preparation of grinding liquid: use deionized water as a solvent to prepare grinding liquid, adjust the pH of the suspension to 9, add PBTCA dispersant with a mass fraction of 0.7%, stir for 5 minutes before use.

[0040] (2) Wafer grinding: use the Logitech-PM5 precision polishing machine imported from the UK to mechanically grind the wafer, using a 4-inch grinding head, a flat glass experimental grinding disc, the grinding disc speed is 10RPM, the grinding pressure is 19N, the grinding time is 5min, and the grinding liquid The flow rate is appropriate to ensure that the liquid fully wets the grinding disc.

[0041] (3) Observation of wafer surface morphology: OLYMPUS-BX51 optical microscope was used to observe the macroscopic morphology of wafer surface after grinding.

[0042] The macroscopic morphology of the wafer surface after gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com