Support structure of reverse counter shaft of transmission

A supporting structure and intermediate shaft technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of increasing oil leakage fault points, complex processing, and affecting the appearance of the transmission, so as to reduce oil leakage The effect of failure point, good support rigidity and good casting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

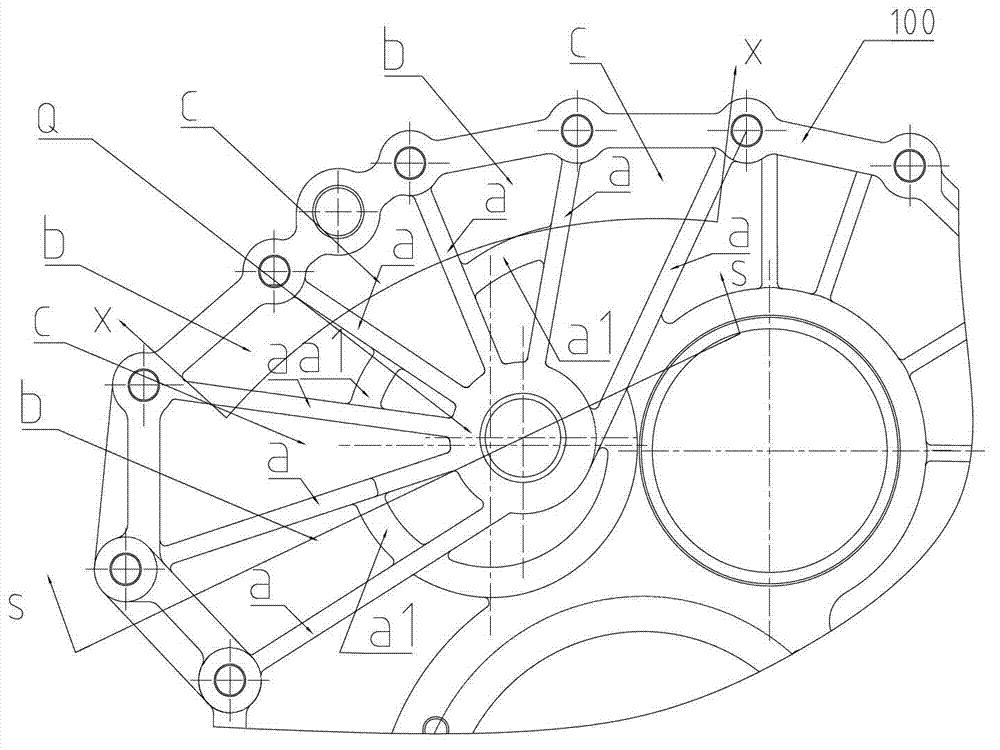

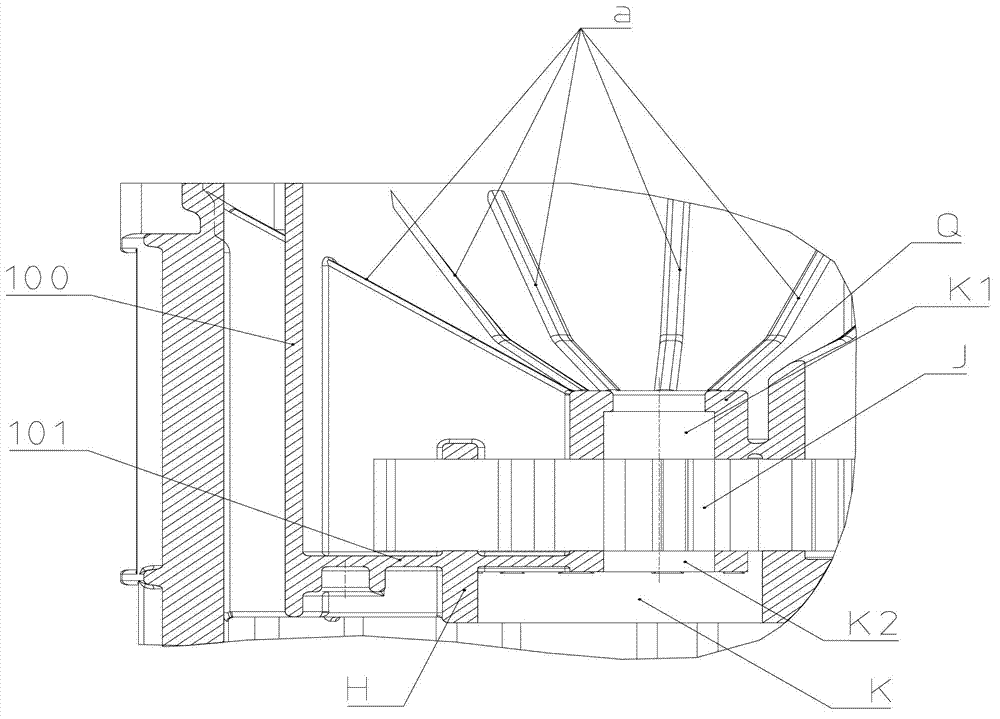

[0025] Please refer to Figure 1 to Figure 7 As shown, a transmission reverse gear intermediate shaft support structure of the present invention is made of aluminum alloy die-casting, including a cylindrical transmission housing 100, and the transmission housing 100 has a partition wall 101 separating the main box and the auxiliary box of the transmission; the partition wall A cylindrical body 102 protrudes from 101 toward the main box, and the side of the cylindrical body 102 close to the transmission housing 100 is supported on the transmission housing 100 by a plurality of ribs a. In order to strengthen the strength of the support of the reverse intermediate wheel 1 and the reverse intermediate shaft 2, the arc-shaped reinforcing rib a1 in Fig. 1 is added between the ribs a without webs.

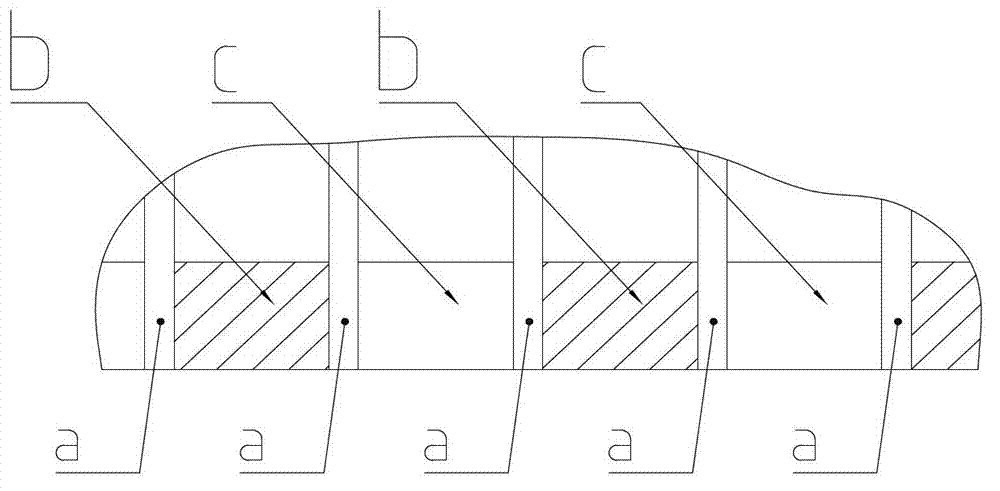

[0026] Displaced webs b or c are arranged between the multiple rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com