Method for manufacturing alumina fiber and titanium oxide particle-reinforced inner-cooling insert ring piston blanks

A particle-enhanced, titanium oxide technology, used in pistons, engine components, mechanical equipment, etc., can solve the problems of poor strength, stability, poor fixing effect, poor piston stability, etc., and achieve good dimensional stability, high density, and improved bearing capacity. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

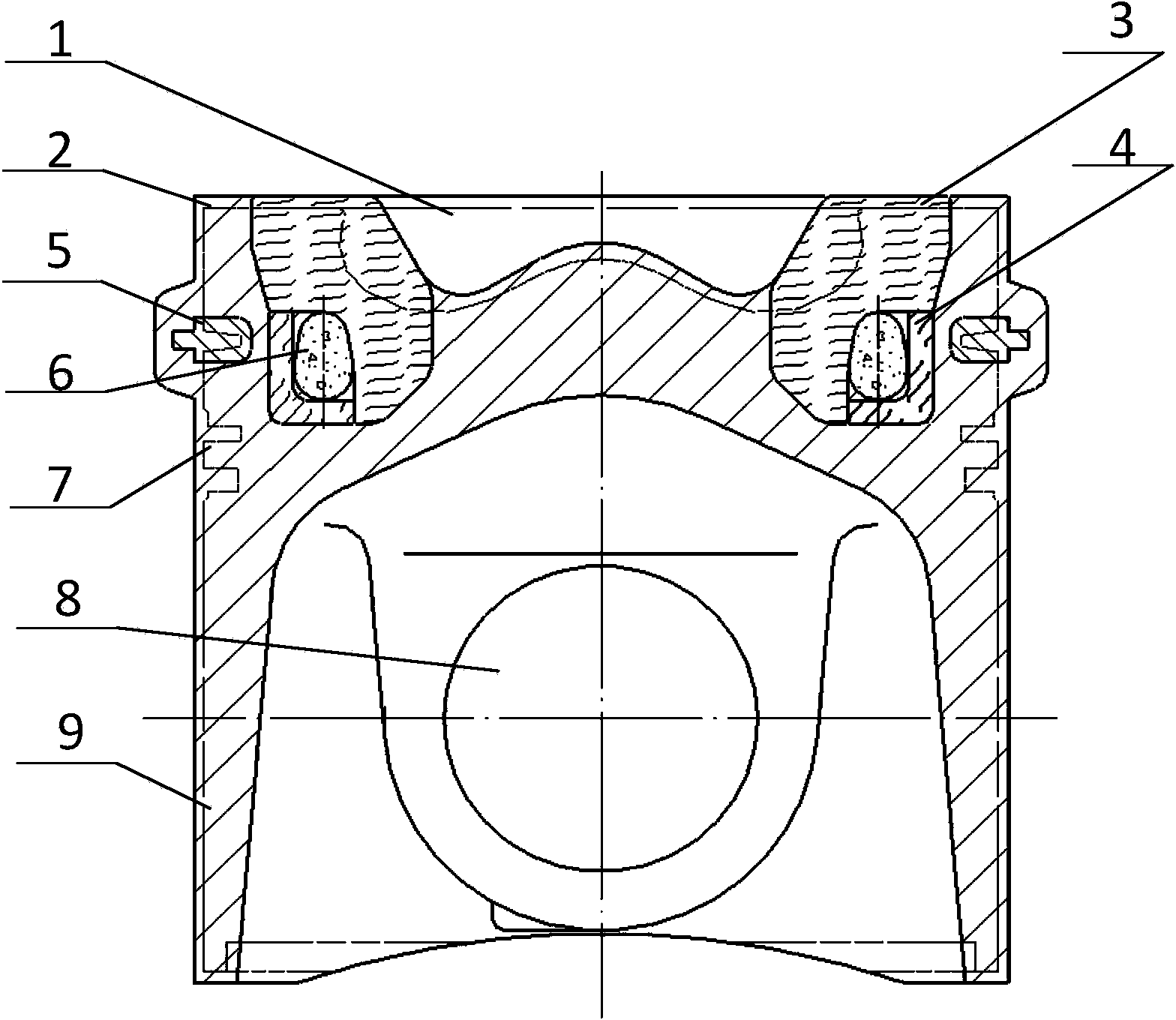

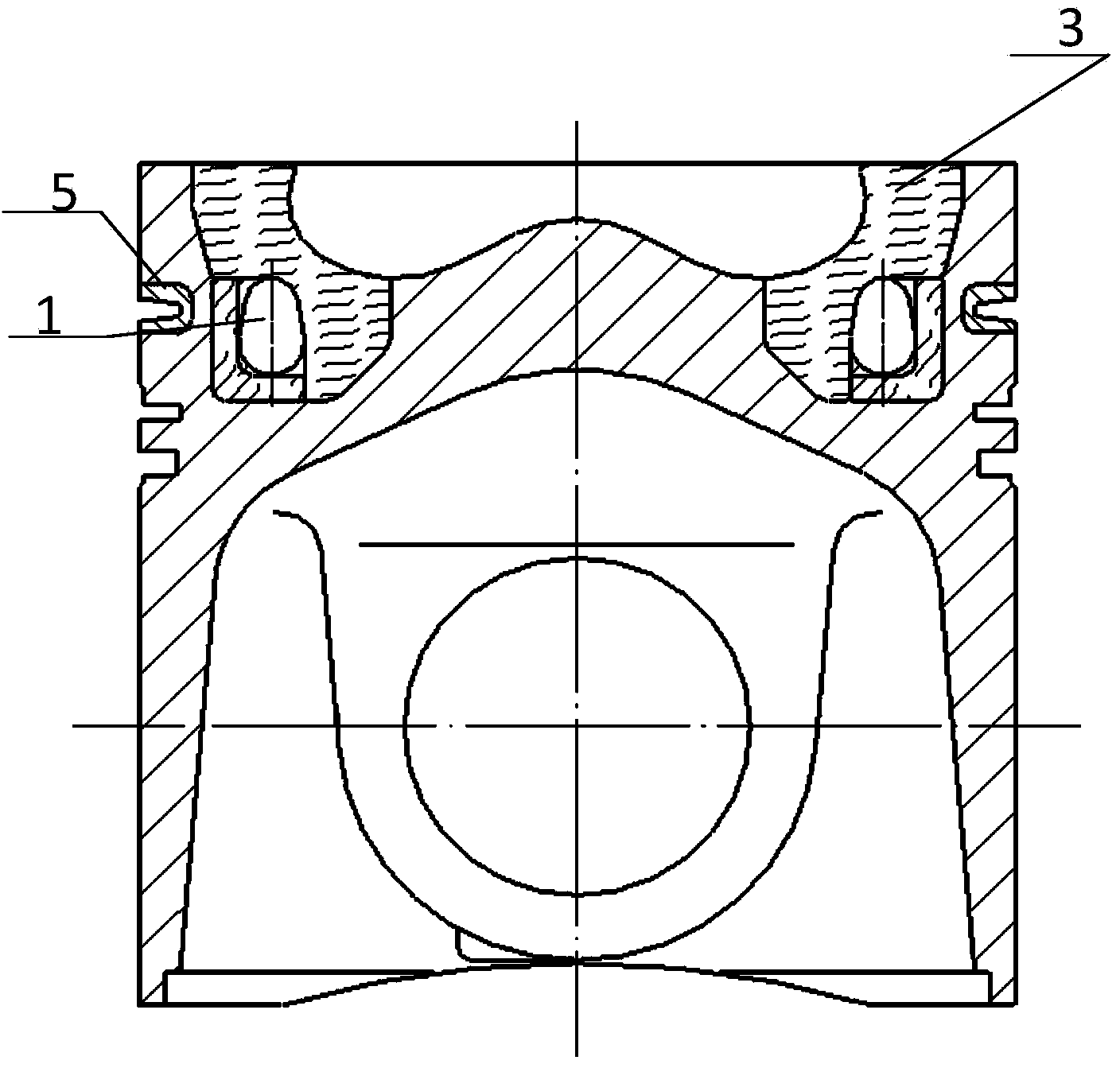

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0040] A method for manufacturing a piston blank with aluminum oxide fiber and titanium oxide particle reinforced inner cooling ring, comprising the following steps:

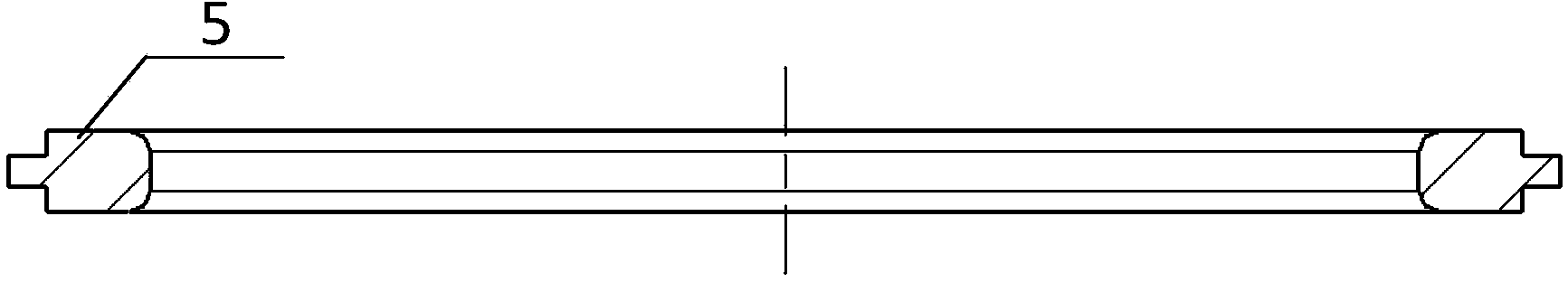

[0041] 1). The upper preform 3 and the lower preform 4 of the two-body alumina ceramic fiber and titanium oxide particles that can be combined up and down are made, wherein the volume fraction of alumina ceramic fiber is 8-25%, and the volume fraction of titania particle is 1- 9%, and the rest are gaps. The manufacturing method of the upper prefab 3 and the lower prefab 4:

[0042] a. Pulverize the alumina ceramic fiber to 10-100 μm.

[0043] b. Weigh the alumina ceramic fiber and titanium oxide particles respectively according to the volume fraction, mix the two, add them into the mixer, and mix them well and evenly.

[0044] c. Put the mixed materials into the molds of the upper pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com