Engine multi-oil channel split type machine body structure

A multi-oil circuit and split-type technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of high risk of cylinder seal failure, difficult to arrange gas distribution, and many combination links, etc., to achieve good lubrication and cooling effects , Large material selectivity, good casting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

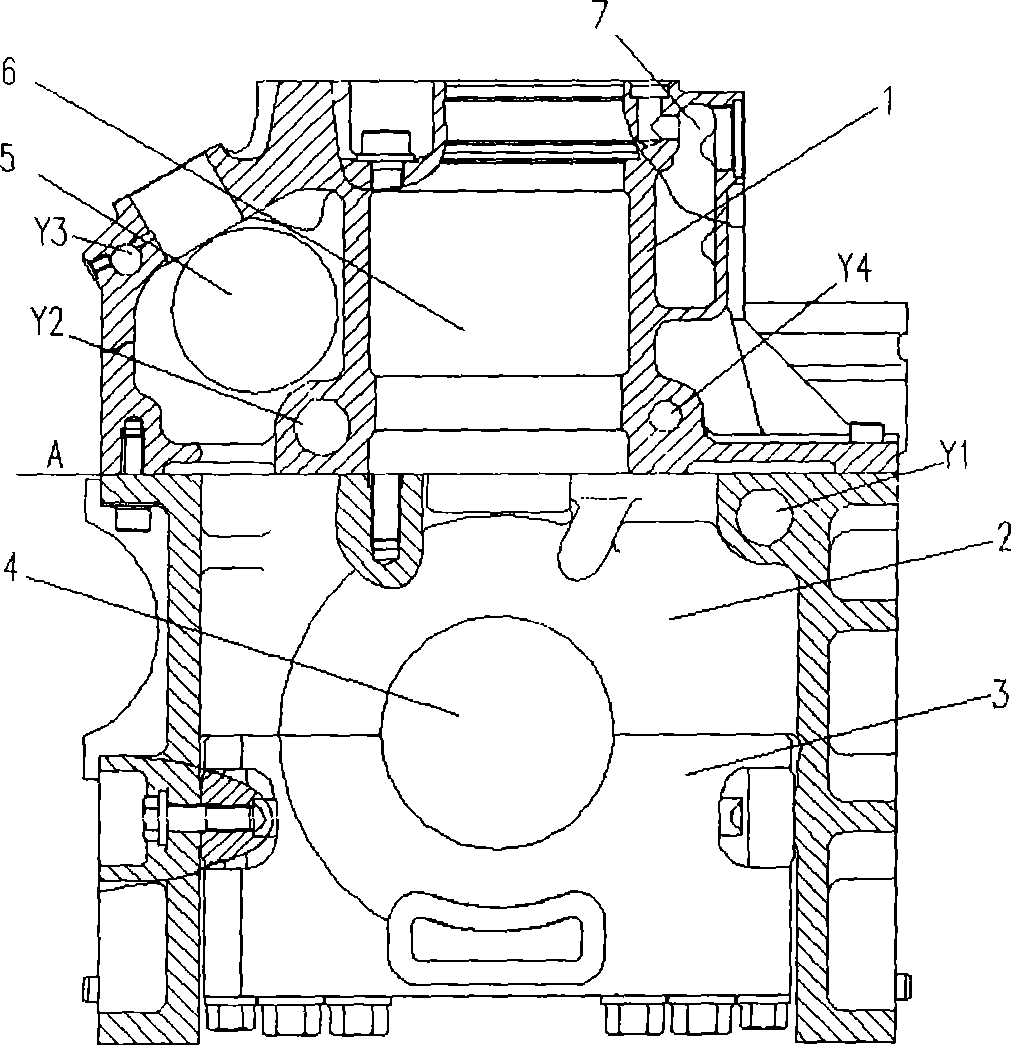

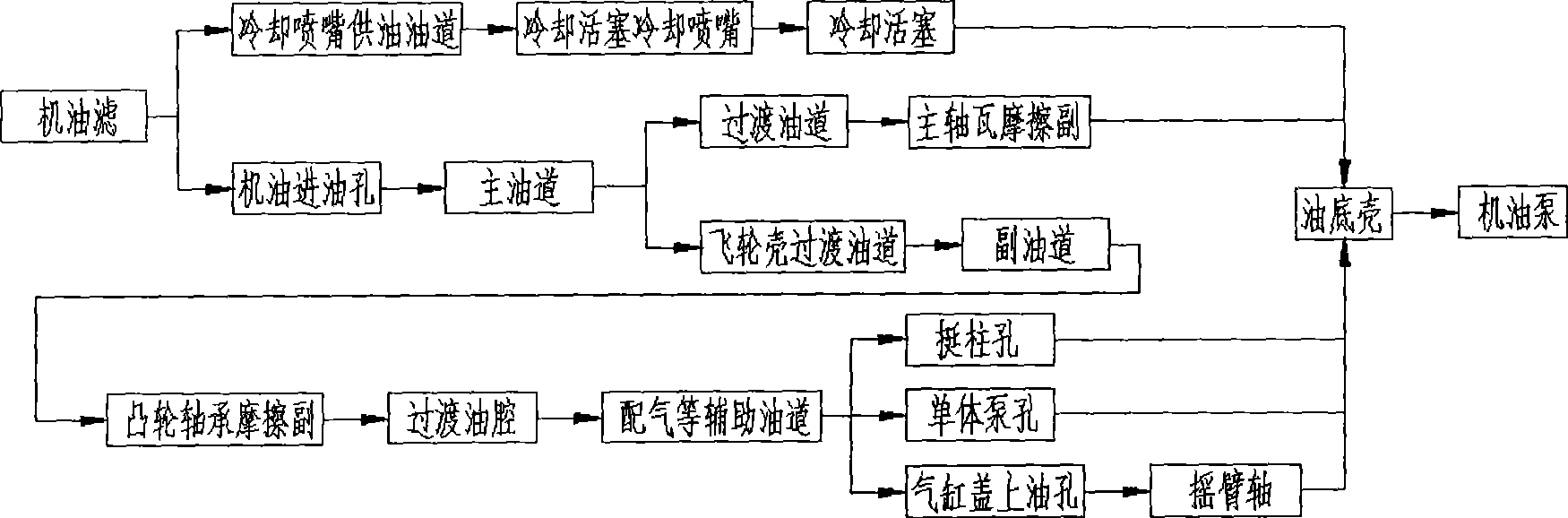

[0012] like figure 1 As shown, an engine multi-oil circuit split body structure includes a cylinder block 1, a crankcase 2 and a bearing cover 3. The cylinder block 1 and the crankcase 2 are positioned by cylindrical pins and connected by high-strength bolts. The crankcase 2 and the bearing The cover 3 is connected by seam positioning and high-strength bolts. The cylinder block 1 and the crankcase 2 are made of cast iron alloy or aluminum alloy, and the bearing cover 3 is made of QT400 or high-quality alloy steel forged blank. The multi-oil circuit split body structure has all the functions of the integral body, which can bear the working load of the diesel engine and play the role of supporting skeleton of related mechanisms and accessories, and provide corresponding movement space and passages required for coolant and lubricating oil. Cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com