High ceramic dielectric capacitor material with reduction resistance

A container material, high dielectric ceramic technology, applied in the field of capacitors, can solve the problems of difficult industrialization, high cost of raw materials, complex process, etc., and achieve the effect of good casting process, low sintering temperature and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The invention provides an anti-reduction high dielectric capacitor material, which is composed of a main material and a modifier; wherein the main material is tetragonal phase BaTiO 3 , granularity D 50 =0.65 μm, purity ≥99.8wt%.

[0034] According to the weight ratio in Table 1, the main materials and modifiers were weighed (in grams), using deionized water as the medium, ball milling and mixing for 5 hours, drying at 120°C for 6 hours, taking out the ceramic powder, grinding and After passing through a 40-mesh sieve, it is packaged and stored in a ziplock bag.

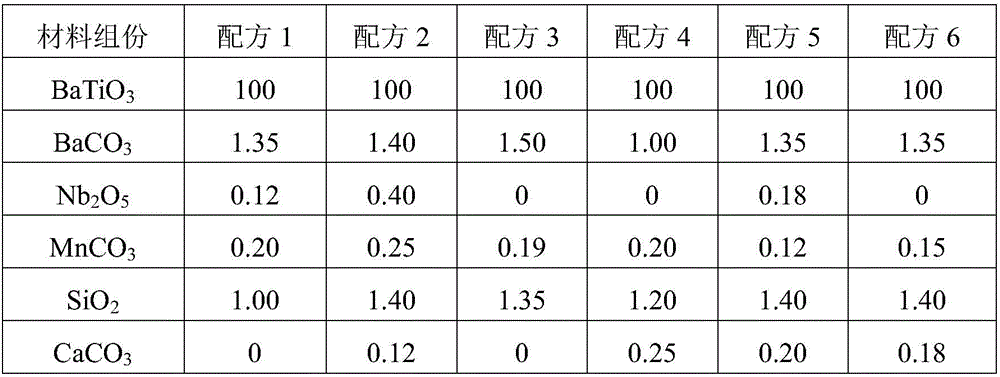

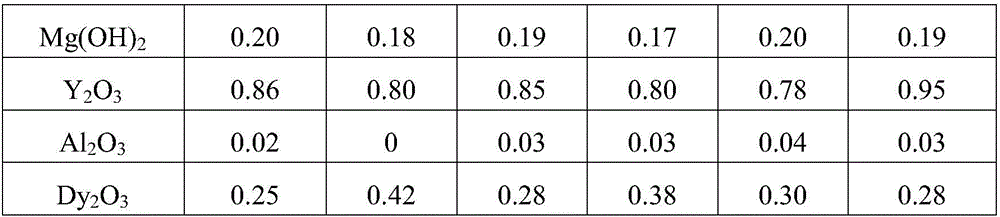

[0035] Table 1

[0036]

[0037]

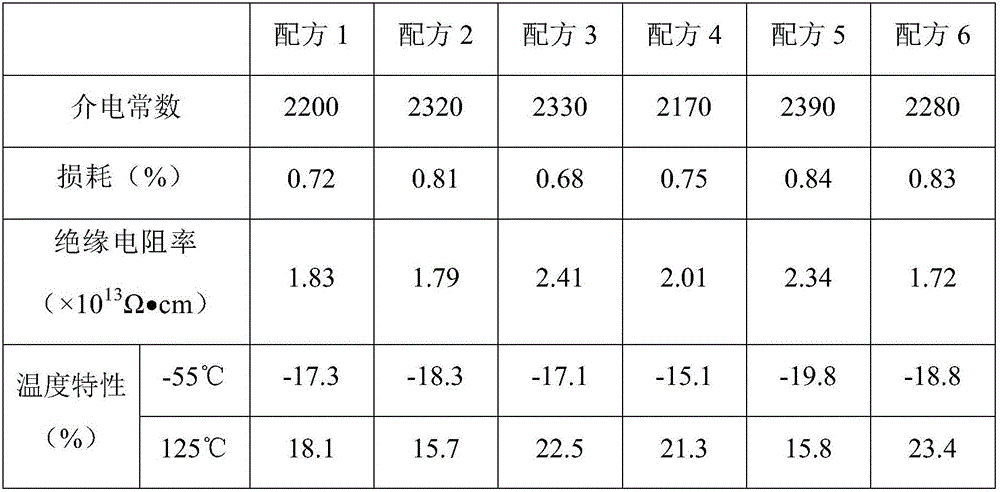

[0038] Performance assessment of the prepared material: Weigh 3g powder material, add 6.5wt% PVA aqueous solution for granulation, press it into a disc with Ф=10mm under 200MPa, sinter in reducing atmosphere, cool with the furnace, and carry out The surface of the sample is treated, and the electrode is coated and sintered. After making a disc capacitor, test the ca...

Embodiment 2

[0045] The invention provides an anti-reduction high dielectric capacitor material, which is composed of a main material and a modifier; wherein the main material is tetragonal phase BaTiO 3 , granularity D 50 =0.75 μm, purity ≥99.8wt%.

[0046] Table 4

[0047] Material composition Recipe 7 Recipe 8 Recipe 9 Recipe 10 Recipe 11 Recipe 12 BaTiO 3

100 100 100 100 100 100 BaCO 3

2.15 1.95 1.50 1.00 2.50 1.55 MnCO 3

0.20 0.14 0.14 0.20 0.15 0.08 SiO 2

1.45 1.50 1.80 1.35 1.10 1.40 CaCO 3

0.10 0.05 0 0.10 0 0 Mg(OH) 2

0.20 0.25 0.19 0.15 0.20 0.19 Y 2 o 3

0.86 0.85 0.85 0.83 0.80 0.65 al 2 o 3

0.05 0.02 0.04 0.04 0.04 0.03 Dy 2 o 3

0.28 0.32 0.30 0.28 0.35 0.45

[0048] According to the weight ratio in Table 4, the main materials and modifiers were weighed (in grams), using deionized water as the medium, ball milling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com