Casting copper-chromium alloy and preparation method thereof

A technology of copper-chromium alloy and copper-chromium, which is applied in the field of casting copper-chromium alloy and its preparation, can solve the problems of poor casting process, low tensile strength, and only 35% pass rate of casting alloys, and achieve the improvement of casting process performance and electrical conductivity. Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with specific examples.

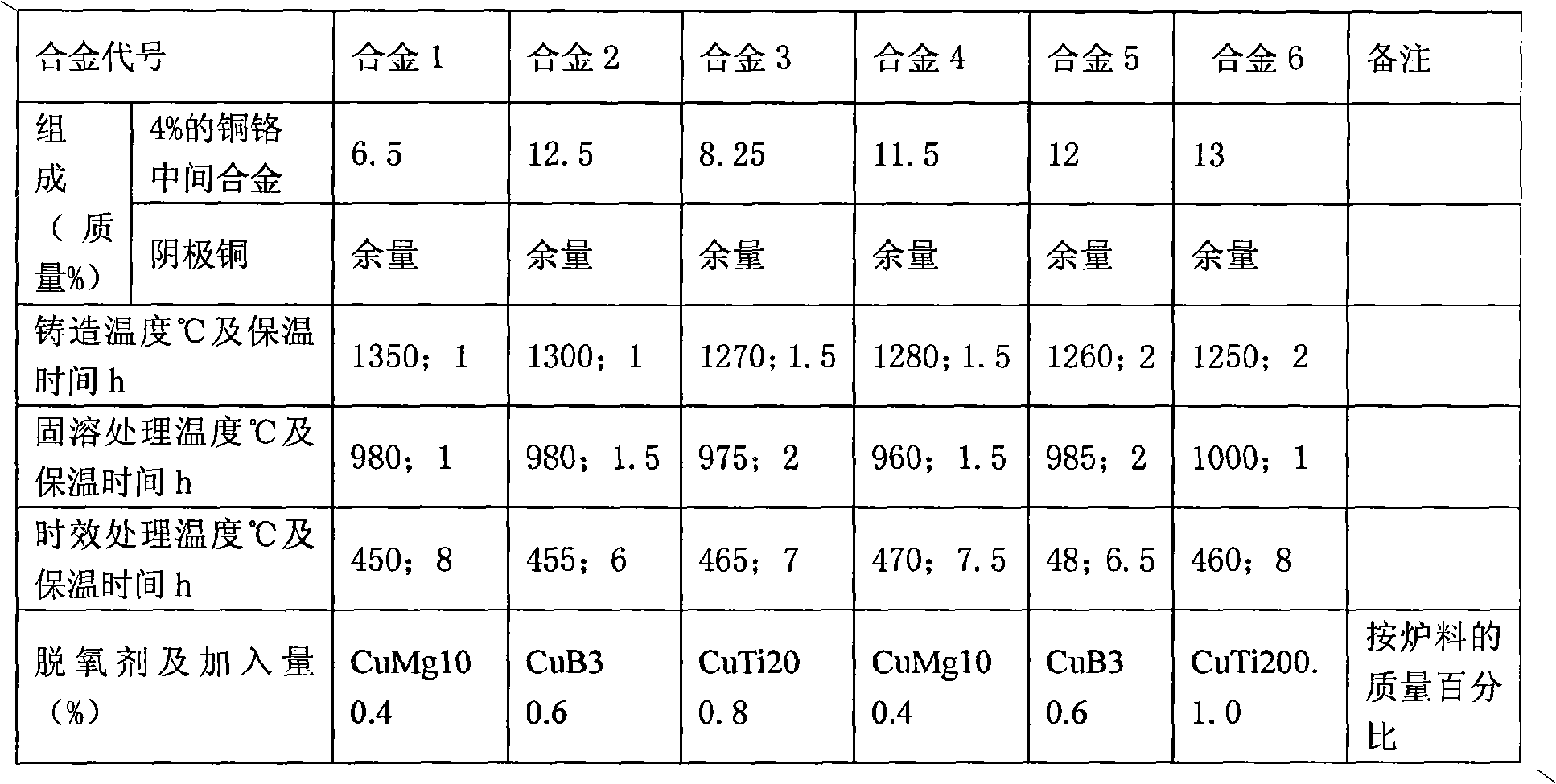

[0016] The cast copper-chromium alloy with high tensile strength comprises the following components by mass percentage: 6.5-13% of copper-chromium master alloy, and the rest is cathode copper; the copper-chromium master alloy contains 4% by mass of chromium. See Table 1 for specific composition

[0017] Table 1

[0018]

[0019] The preparation method of the cast copper-chromium alloy of table 1 composition:

[0020] (1) First prepare copper-chromium master alloy, weigh 4% chromium according to the mass percentage, and the balance is cathode copper, put it in a graphite crucible and place it in an induction furnace to heat up to 1250-1300°C, and after fully melting, cool to obtain copper Chromium master alloy;

[0021] (2) then take by weighing the intermediate alloy ingot obtained in the above steps according to the specific composition in table 1, and the bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com