Multi-layer composite PVC (polyvinyl chloride) floor glue with high wear resistance and acid and alkali resistance as well as preparation and application thereof

A multi-layer composite, acid and alkali resistant technology, applied in the field of building materials, can solve the problems of poor wear resistance, non-flame retardant, difficult to achieve special industrial floors, etc., to improve the pressure resistance, good resilience, easy installation and laying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

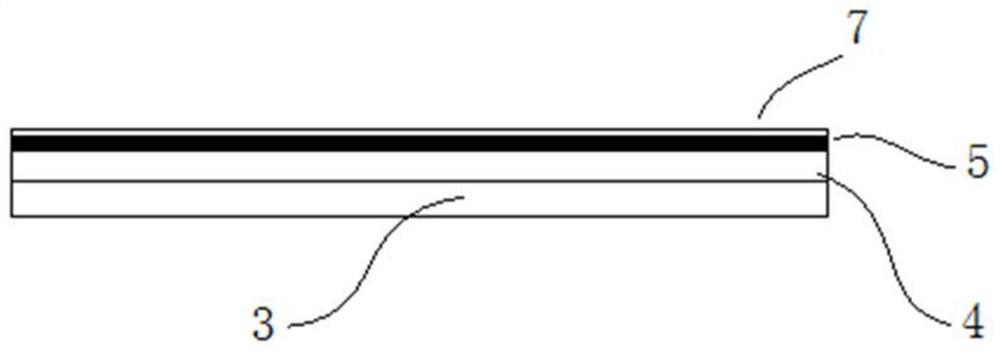

[0044] This embodiment provides a kind of multi-layer composite high wear-resistant and acid and alkali resistant PVC floor glue, such as figure 1 As shown, it includes an epoxy resin surface wear-resistant layer 7, a glass fiber reinforced PVC middle layer 5, a PVC elastic layer 4 and a glass fiber reinforced PVC base layer 3 sequentially compounded from top to bottom;

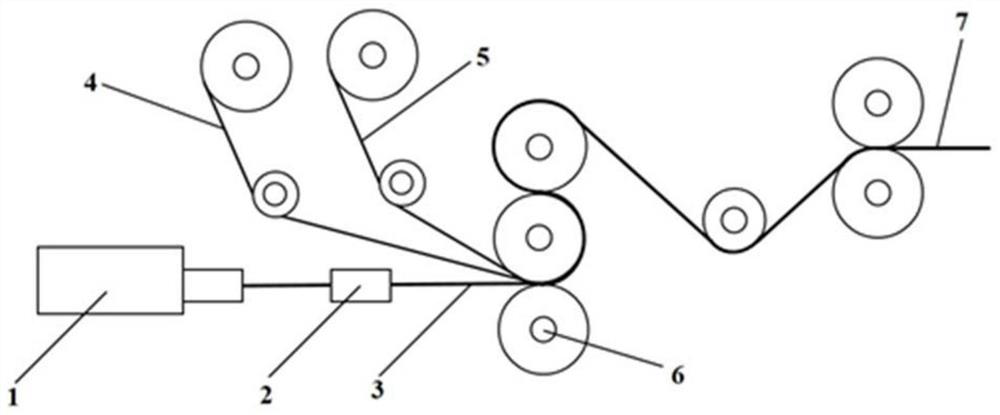

[0045] For the entire preparation process, see figure 2 As shown, the details are as follows:

[0046] (1) Add the measured construction waste PVC recycled materials, stabilizers, plasticizers, glass fibers, etc. into a high-speed mixer with a temperature of 150°C and a stirring speed of 700r / min in the order of solid first and then liquid, and stir for 15 minutes , so that the PVC and additives are mixed evenly, and the liquid additives are completely absorbed by the solid. In this embodiment, the material ratio of each layer is as follows:

[0047] Glass fiber reinforced PVC base layer 3: 100 parts of PVC ...

Embodiment 2

[0060] Compared with Example 1, in the step (1), the mixing time of PVC recycled material, stabilizer, plasticizer, glass fiber, etc. in the high-speed mixer is changed to 20min, and other conditions remain unchanged.

Embodiment 3

[0062] Compared with Example 1, the auxiliaries such as PVC recycled material, foaming agent, stabilizer, plasticizer in the step (1) are changed into 900r / min in the high-speed mixer, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com