Terylene grey fabric pretreating device

A cloth feeding device and gray cloth technology are applied in the processing of textile materials, processing textile material carriers, liquid/gas/steam textile material processing, etc., which can solve problems such as unstable product quality, high water consumption, and complicated procedures, and achieve The effect of relieving the pressure of sewage treatment, reducing sewage discharge, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

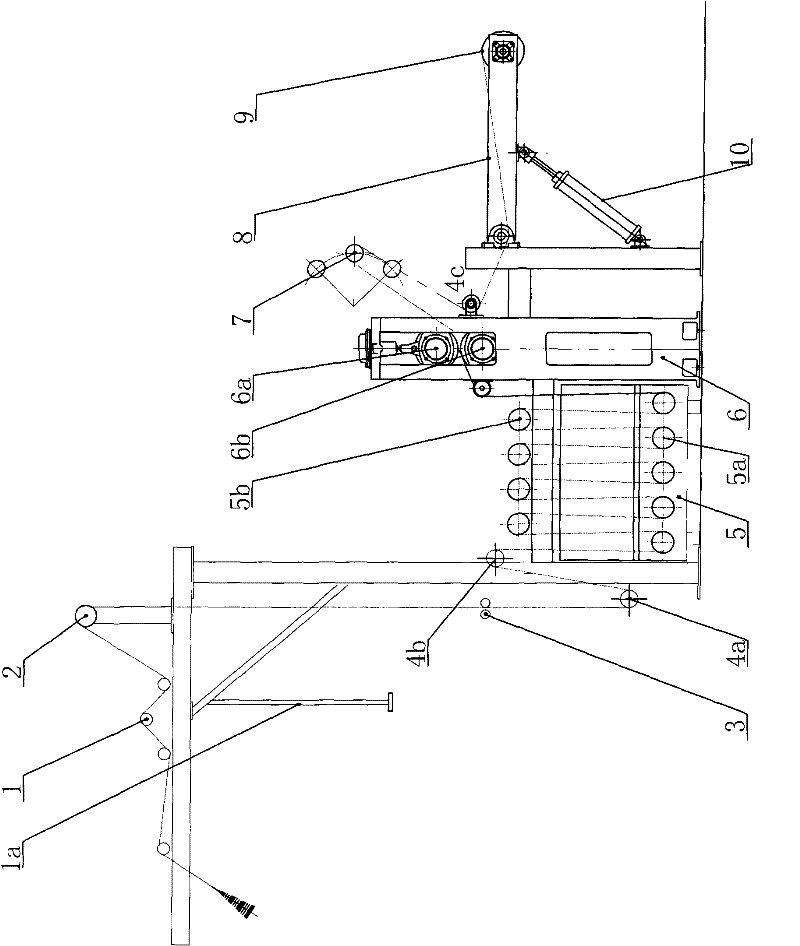

[0010] Such as Figure 1 As shown, the pretreatment device of the polyester gray cloth of the present invention sequentially includes a cloth feeding device, an alkali tank 5, a padding car 6 and a cloth discharging device. The cloth feeding device includes a cloth tensioner 1, a high-position cloth guide roller 2, a centering device 3 and a cloth guide roller. The rear end of the beam is connected to the top of the column, and the centering device 3 is installed in the middle of the column;

[0011] The tank bottom of the alkali tank 5 is equipped with several immersion rollers 5a, and the top of the alkali tank 5 is equipped with cloth guide rollers 5b corresponding to each immersion roller; the rear of the alkali tank 5 is equipped with a rolling car 6, and the rolling car 6 includes an upper roll 6a And lower roll 6b; The back side of paddle car 6 is equipped with the tension pendulum roll 7 that adjusts cloth tension.

[0012] The cloth output device includes a swing arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com