Production system and process method for continuously synthesizing bisazo pigment

A production system, bisazo technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve problems such as unsuitable azo pigments, no process parameters, and no structural parameters of microchannel reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

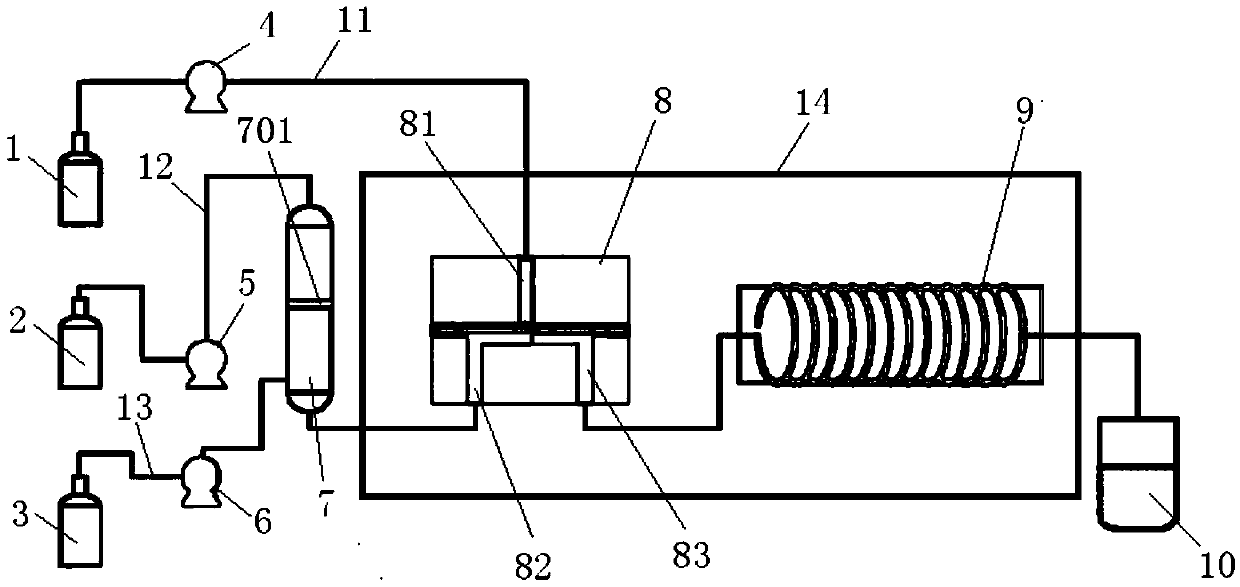

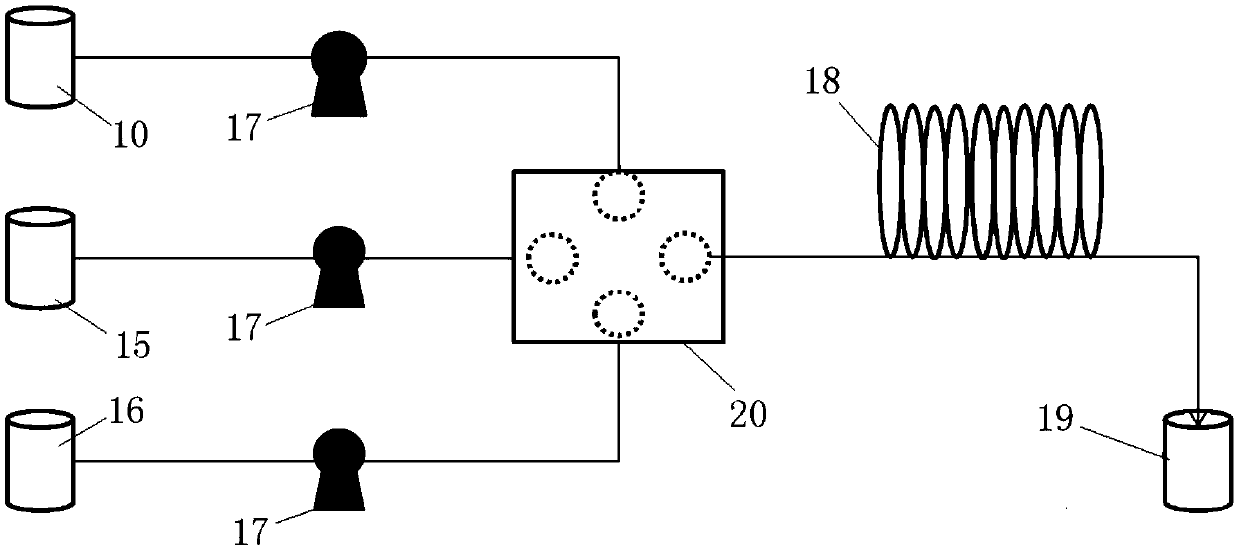

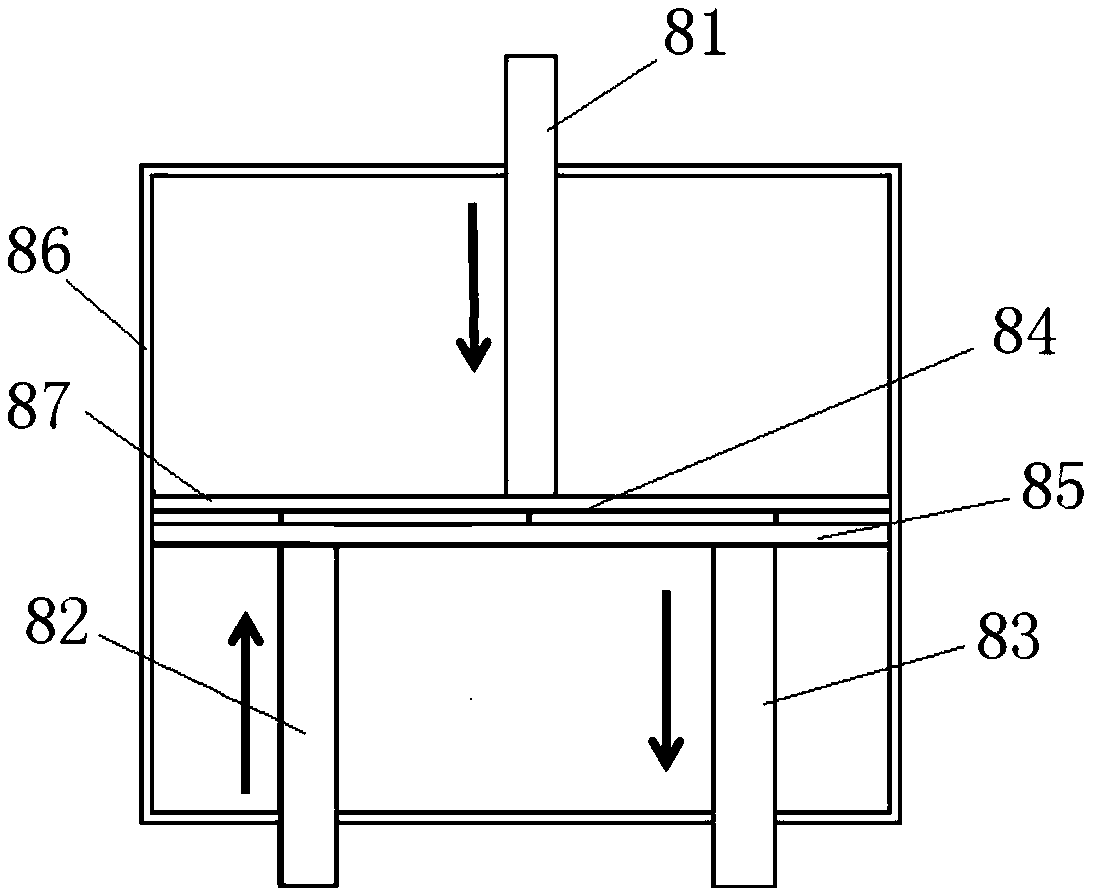

[0049] Such as Figure 1-8 Shown, the present invention includes continuous diazotization device and continuous coupling reaction device, wherein such as figure 1 As shown, the continuous diazotization device includes a sodium nitrite solution storage tank 1, a water storage tank 2, a slurry storage tank 3, a high-pressure tank 7, a membrane dispersion microreactor 8, a first delay tube 9 and a diazonium salt solution Storage tank 10, wherein film dispersion microreactor 8 is provided with dispersed phase fluid inlet pipe 81, continuous phase fluid inlet pipe 82 and mixed solution outlet pipe 83, sodium nitrite solution storage tank 1 passes through the first nitriding pipeline 11 and The dispersed phase fluid inlet pipe 81 is connected, and the first nitriding pipeline 11 is provided with the first nitriding input pump 4, and the high pressure tank 7 is provided with an elastic sealing sheet 701, and the water storage tank 2 The second nitriding pipeline 12 is connected to t...

Embodiment 2

[0059] When the above system is working, the liquid in the slurry storage tank 3 is preferentially flowed into the lower part of the high-pressure tank 7 by using the third nitriding input pump 6, and the input is stopped after the high-pressure tank 7 is filled, and the solution in the sodium nitrite solution storage tank 1 passes through the first The nitriding pipeline 11 flows into the dispersed phase fluid inlet pipe 81, and flows into the diazotization microchannel 851 of the continuous diazotization device after passing through the porous dispersion membrane 84, and the water in the water storage tank 2 passes through the second nitriding input pump 5 enters the upper part of the high-pressure tank 7, and the slurry is pressed into the membrane dispersion microreactor 8 through the sealing sheet 701 in the high-pressure tank 7, and then flows into the diazotization microchannel 851 through the continuous phase fluid inlet pipe 82, the After the reaction of the solution i...

Embodiment 3

[0068] (1) At room temperature (25°C), take 17.25g of 3,3'-dichlorobenzidine hydrochloride (DCB hydrochloride) in a 500mL beaker, add 17.75g of concentrated hydrochloric acid (37%), and 250mL of deionized water, stirring to obtain a uniform DCB hydrochloride slurry; take 7.11g of sodium nitrite solid in a 500mL beaker, add 250mL of deionized water, and stir until the sodium nitrite solid is completely dissolved to obtain a sodium nitrite solution;

[0069] (2) Under the ice water bath of 0-4 ℃, adopt the 3rd nitriding input pump 6 (peristaltic pump) to squeeze all DCB hydrochloride slurry into the high-pressure tank 7, then use the 2nd nitriding input pump 5 (advection pump) ) and high-pressure tank 7 to control the flow of DCB hydrochloride slurry to be 30ml / min, and to control the flow of sodium nitrite solution with the first nitriding input pump 4 (advection pump) to be 30ml / min, and the two solutions are micro-reacted in the membrane dispersion The mixing reaction was car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com