Main reducing gear shell and main reducing assembly

A technology of the main reducer and oil baffle, which is applied to transmission parts, components with teeth, belts/chains/gears, etc., which can solve the difficulty of universalizing the main reducer shell, increase product types and development costs, and reduce Issues such as the versatility of the main reduction assembly in the drive axle have achieved strong market promotion value, high support rigidity, and reduced development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

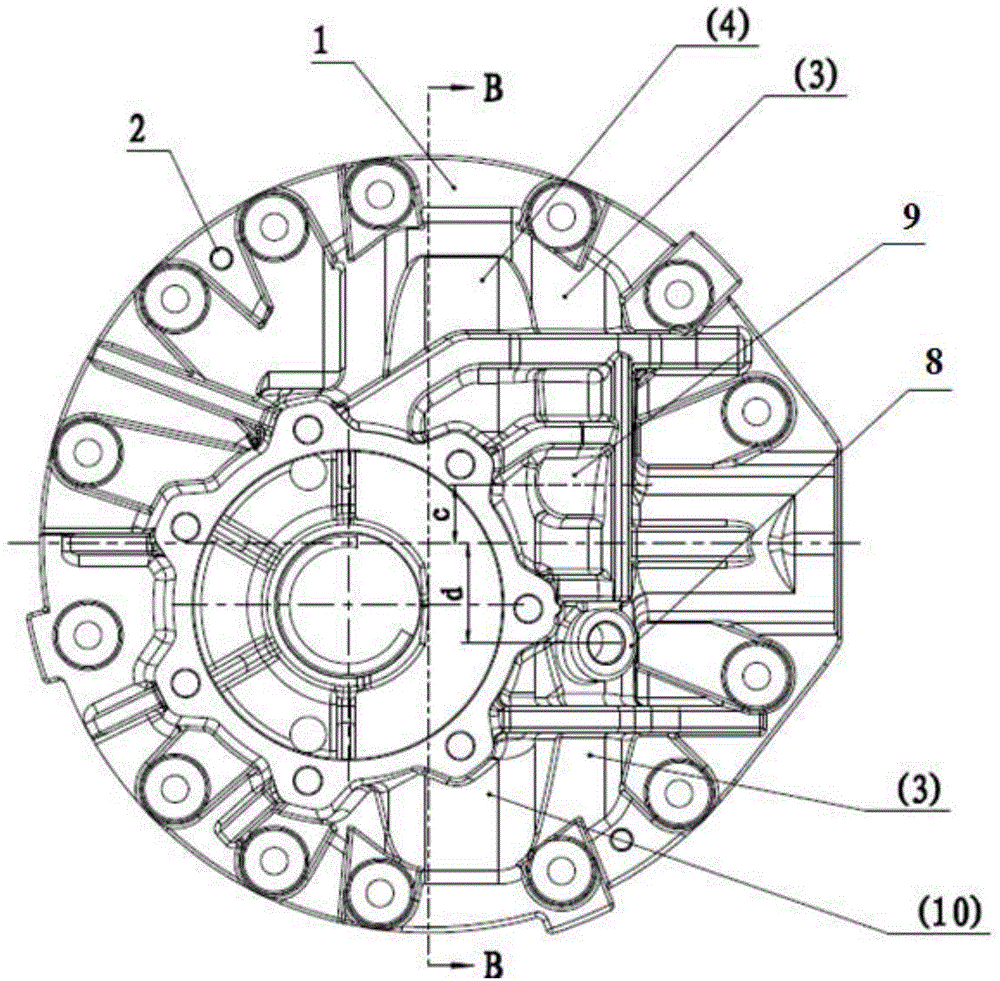

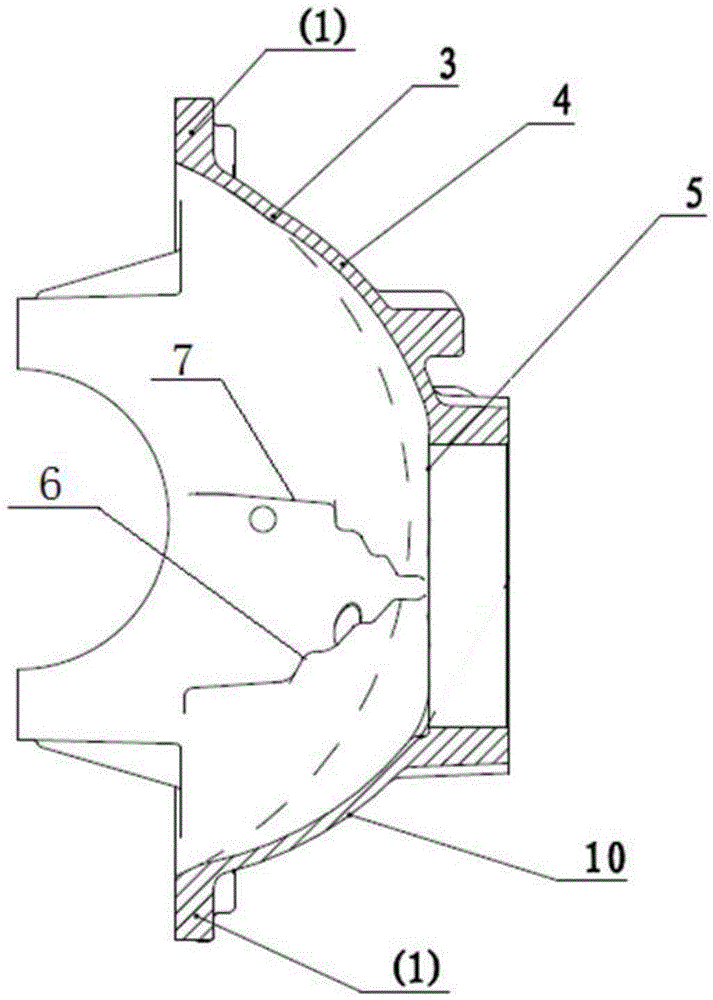

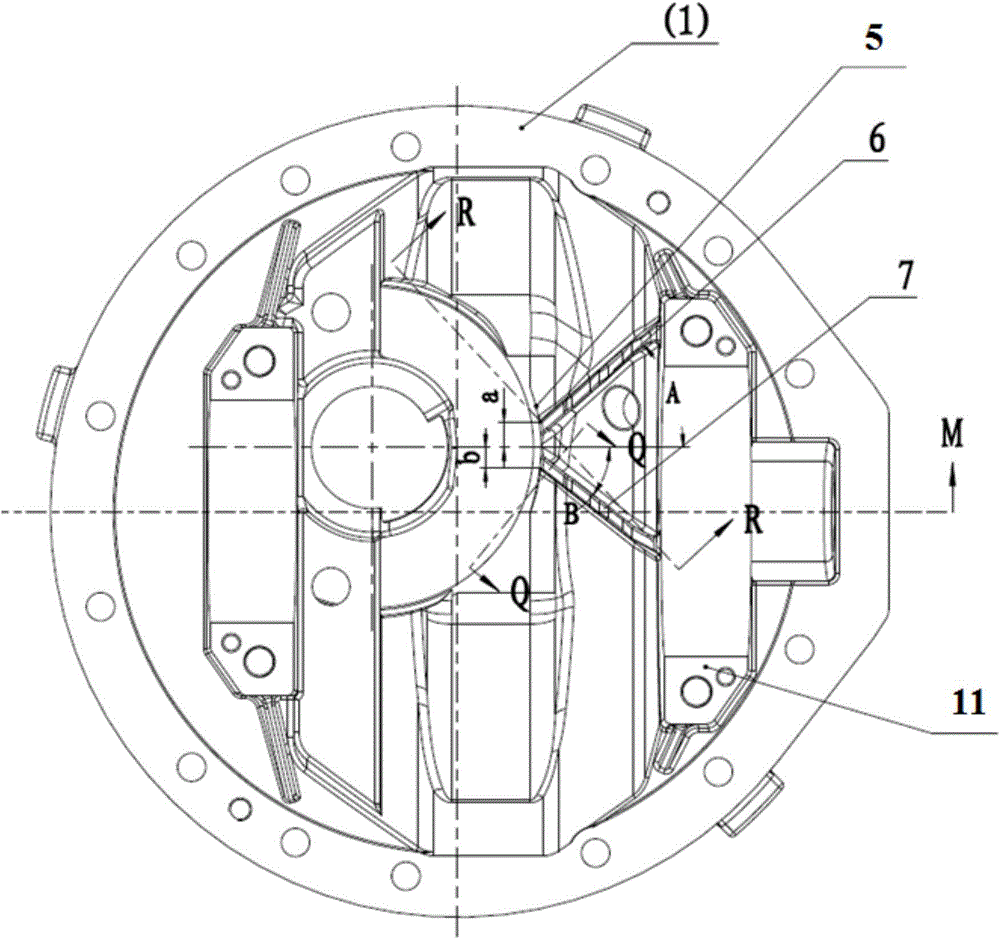

[0027] combined with figure 1 to attach image 3 As shown, the main reducer housing provided by the present invention includes a large surface 1 for reducing the casing, a rotating base 3, a first raised arc 4, a second raised arc 10 and a bearing mounting hole 5. The reduced casing The large surface 1 has an approximate ring shape as a whole, and extends inwardly along the inner edge of the ring to form the rotating base 3 , and the rotating base 3 protrudes from the inner side along the axial direction of the ring to form the convex arc , the bearing seat installation hole 5 is formed on the inner side of the raised arc, wherein the bearing seat installation hole 5 preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com