Hot rolling method of niobium-containing austenitic stainless steel profile

A niobium austenitic and stainless steel technology, which is applied in the field of hot rolling of niobium-containing austenitic stainless steel, can solve the problems of narrow thermal processing window, lower material thermoplasticity, and low production efficiency, and achieve good structure uniformity and good thermal perforation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The elemental composition (% by weight) of the niobium-containing austenitic stainless steel of this embodiment is as follows:

[0080] Element C Si Mn P S Cr Ni Nb N content 0.05 0.21 0.76 0.024 0.001 25.1 20.3 0.40 0.26

[0081] In this embodiment, the ingot size is Φ440mm, and the target size is 150mm×150mm.

[0082] The hot rolling process of this embodiment is as follows:

[0084] Casting the refined molten steel into a round ingot, Dmax=440mm, Dmin=390mm, H=1820mm, the taper is 2.7%, and the volume ratio is 9%.

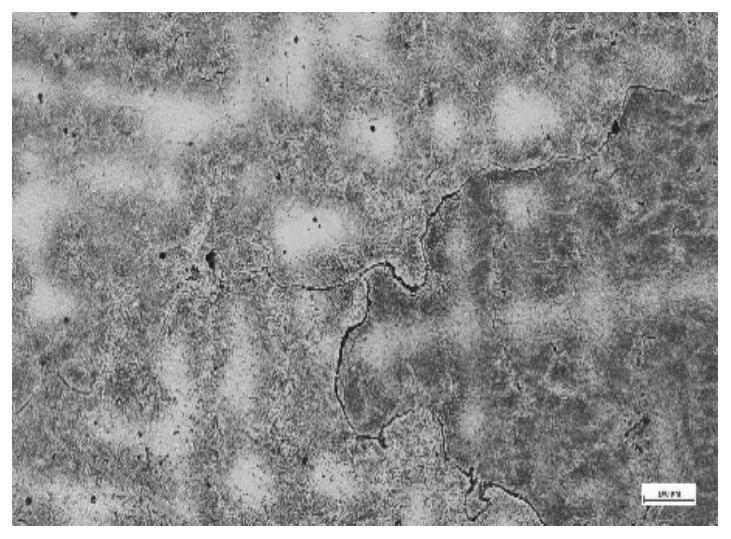

[0085] The columnar crystal structure of the ingot is figure 1 shown.

[0086] 2. Steel ingot heating: the target heating temperature is 1270℃, the holding time is 472min, and t1=300.

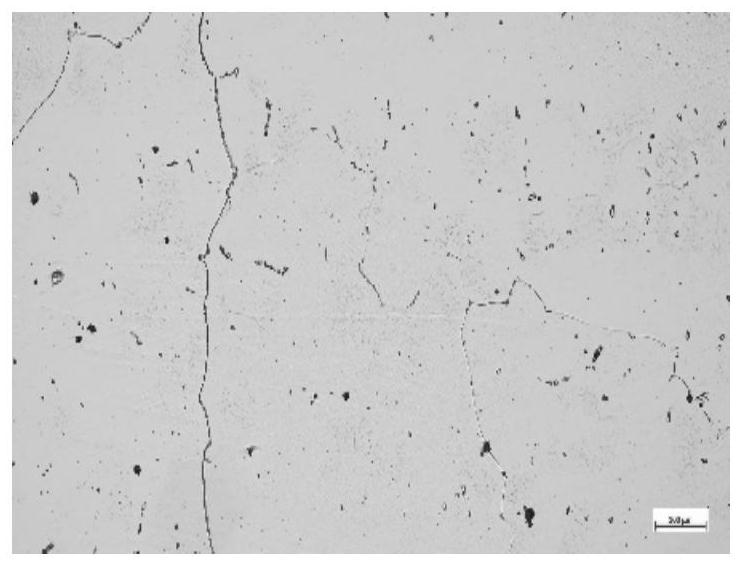

[0087] After heating, the columnar crystal structure of the ingot is as follows figure 2 shown.

[0088] 3. Billet rolling:

[0089] The start rolling temperature is 1140°C, the rolling process and...

Embodiment 2

[0093] The elemental composition (% by weight) of the niobium-containing austenitic stainless steel of this embodiment is as follows:

[0094] Element C Si Mn P S Cr Ni Nb N content 0.05 0.13 0.87 0.028 0.001 24.9 21.1 0.45 0.22

[0095] In this embodiment, the ingot size is Φ400mm, and the target bar size is Φ110mm.

[0096] The hot rolling process of this embodiment is as follows:

[0098] Cast the refined molten steel into a round ingot, Dmax=380mm, Dmin=362mm, H=1920mm, the taper is 0.94%, and the volume ratio is 8%.

[0099] 2. Steel ingot heating: target heating temperature 1250℃, holding time 400min, t1=220.

[0100] 3. Billet rolling:

[0101] The start rolling temperature is 1120°C, the rolling process and the finishing rolling temperature are 910°C. The single-pass reduction is controlled at 10-70mm. Overall compression ratio: 13.2. Finished product specification: Φ110mm bar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com