Production method for rolling and cogging big cast ingot of high-carbon high-alloy cold-working die steel

A technology of cold working die steel and production method, which is applied in the field of metallurgy, can solve problems such as inability to hot-process and roll billet, and achieve the effects of convenient production organization, reduced metallurgical manufacturing cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

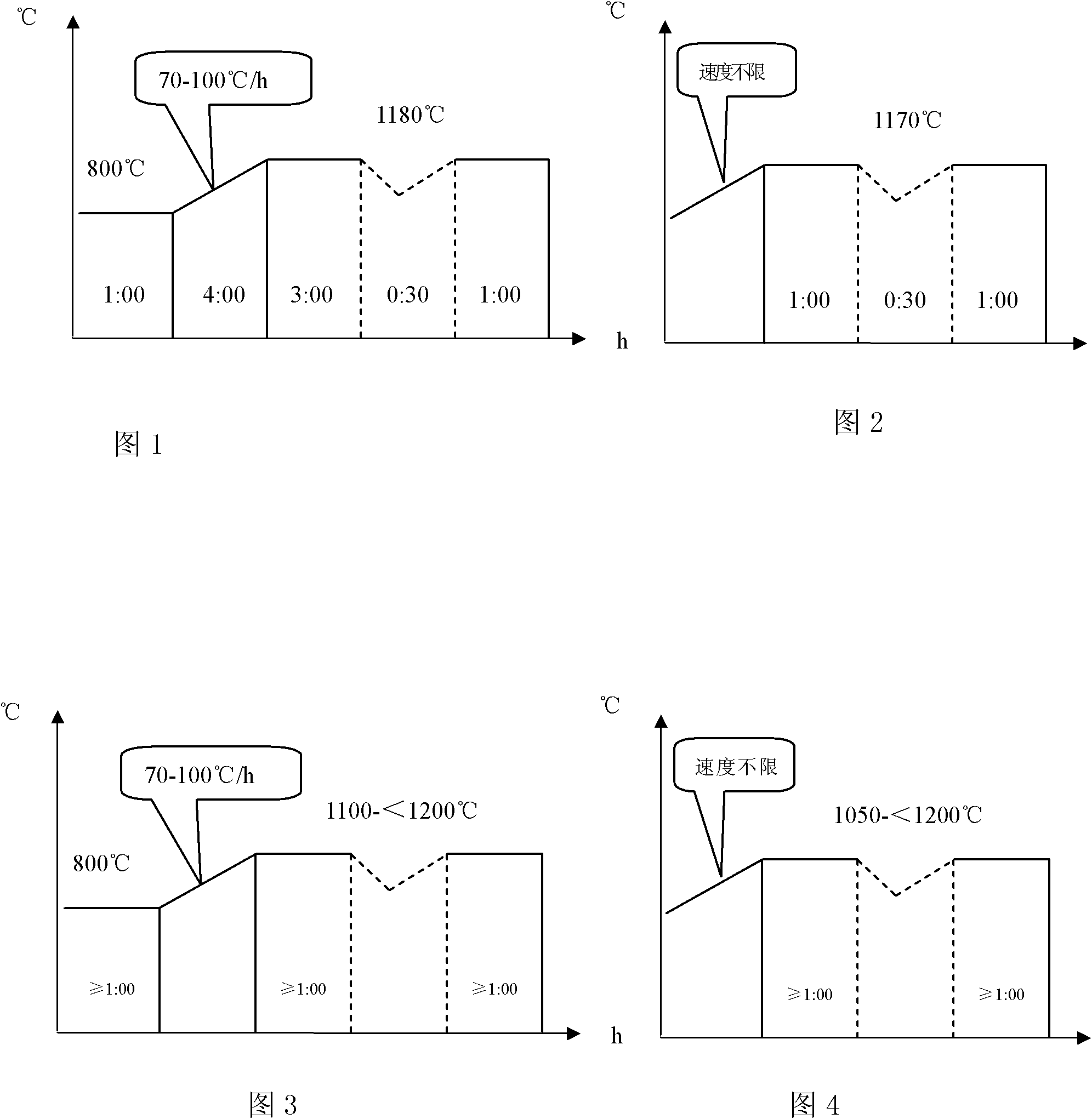

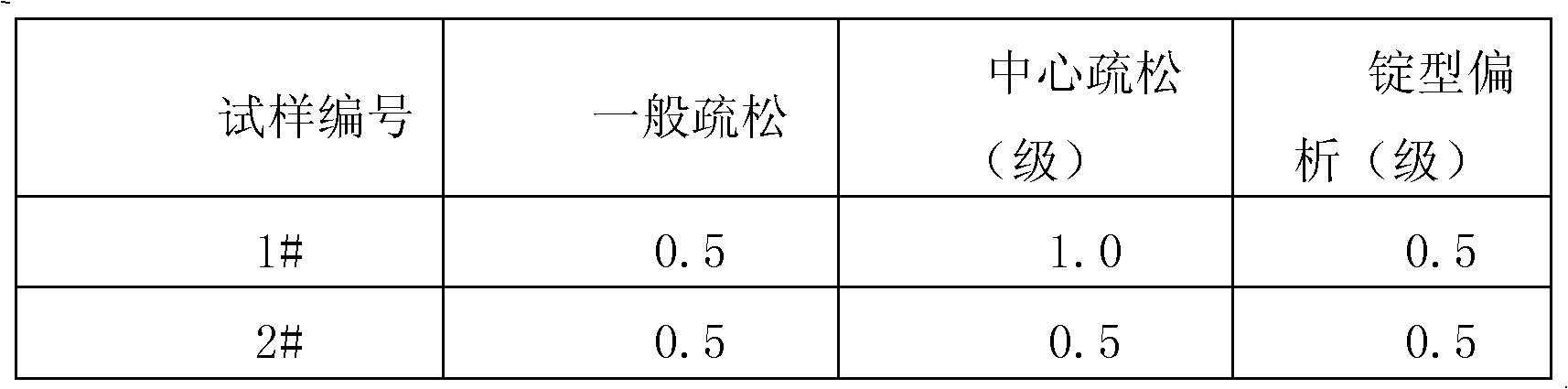

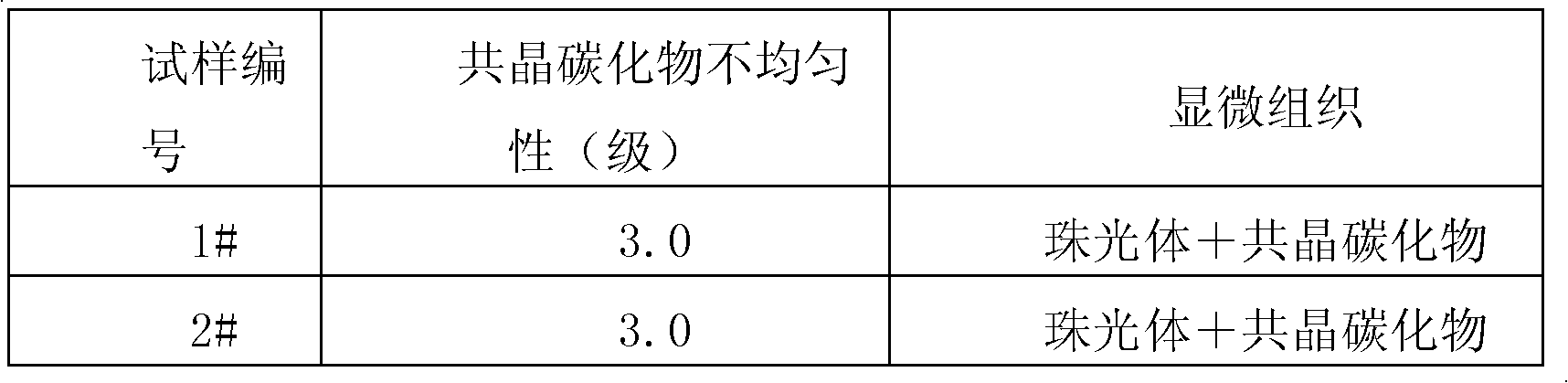

[0056] The ingot is heated and homogenized by soaking furnace hot charging (ingot weight 2.31 tons) + hot rolling in the blooming mill (800 rolling mill) for hot processing to produce X210CrW12 billet (140×140mm).

[0057] Ingot type: 2.3t ingot Ingot side length: Steel type: X210CrW12. Bloom specification: 140×140mm

[0058] During the first-fire ingot heating process before the first-fire rolling of the blooming mill, the smelting and casting of 2.31 tons of ingots is hot-sent to the soaking furnace for heating:

[0059] (A) The furnace temperature of the ingot is ≤800°C, and the temperature is kept for 1 hour;

[0060] (B) When heating up, heat up to 1180°C at a rate of ≤100°C / h;

[0061] (C) At a temperature of 1170-1180°C, heat the ingot for 3.0 hours (homogenization treatment), then turn over the ingot one by one, and keep the overturned ingot for another 1.0 hour to reduce the temperature difference between the positive and negative sides of the ingot ;

[0062] (D)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com