Method for preparing polymer ceramic dispersants

A polymer ceramic and dispersant technology, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problems of limited dispersion effect and large dosage, achieve good dispersion effect, enhance dispersion performance, and broaden the application field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

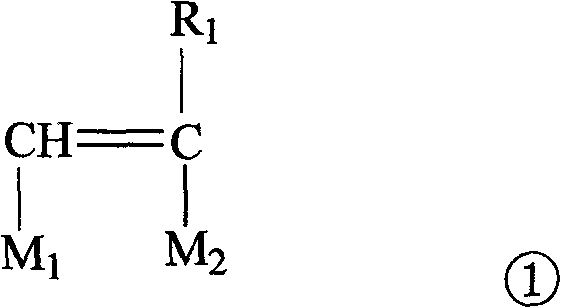

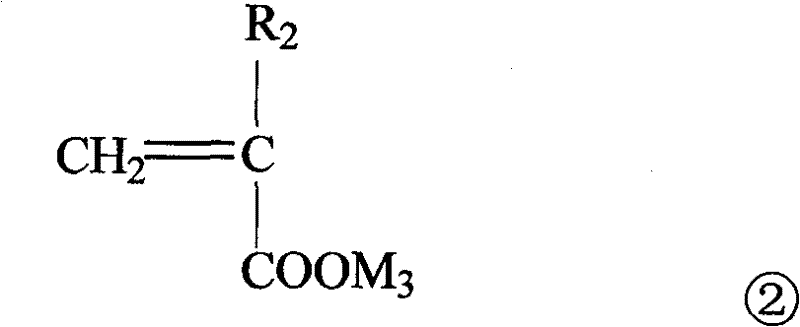

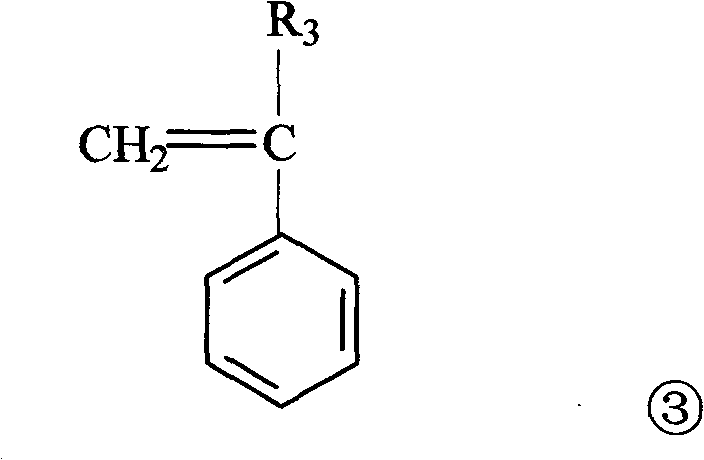

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Polyethylene glycol (PEG200) and maleic anhydride were mixed uniformly at a molar ratio of 1:0.8 to prepare solution A; pure sulfuric acid was added to solution A, and the mass ratio of solution A to acid was 100:3 , then heated up to 30°C, and reacted for 4 hours to obtain an esterified product B; the product B, functional monomer acrylic acid and vinyl monomer methyl acrylate were mixed uniformly in a mass ratio of 1:1:1.5 to obtain Monomer solution C; mix solution C and water uniformly in a mass ratio of 1:8 to obtain monomer mixed solution D; mix water and water-soluble initiator ammonium persulfate uniformly in a mass ratio of 1:0.002 to obtain initiator Agent aqueous solution E; at 80°C, add dropwise initiator aqueous solution E to the monomer mixed solution D, wherein the mass ratio of the monomer mixed solution D to the initiator aqueous solution E water-soluble initiator is 100:10, and the dropping time is After 2 hours, after the dropwise addition, ...

Embodiment 2

[0015] Example 2: Polyethylene glycol (PEG400) and maleic anhydride were mixed uniformly at a molar ratio of 1:0.5 to prepare solution A; pure formic acid was added to solution A, and the mass ratio of solution A to acid was 100:5 , then heated up to 40°C, reacted for 3.5 hours, and obtained esterification product B; product B, functional monomer methacrylic acid and vinyl monomer methyl methacrylate were mixed in a mass ratio of 1:3:1.2 homogeneously, monomer solution C is obtained; solution C, molecular weight regulator ethanethiol and water are mixed uniformly in a mass ratio of 1:0.04:5 to obtain monomer mixed solution D; water is mixed with water-soluble initiator persulfuric acid Potassium is uniformly mixed at a mass ratio of 1:0.005 to obtain an aqueous initiator solution E; at 50°C, add the aqueous initiator solution E dropwise to the monomer mixed solution D, wherein the monomer mixed solution D and the aqueous initiator E solution are water-soluble to initiate The m...

Embodiment 3

[0016] Example 3: Polyethylene glycol (PEG600) and maleic anhydride are mixed uniformly at a molar ratio of 1:1.0 to prepare solution A; pure acetic acid is added to solution A, and the mass ratio of solution A to acid is 100:8, Then the temperature was raised to 50° C. and reacted for 3 hours to obtain the esterification product B; the product B, the functional monomer itaconic acid and the vinyl monomer ethyl acrylate were uniformly mixed in a mass ratio of 1:8:0.8 to prepare Obtain monomer solution C; Mix solution C, molecular weight regulator triethanolamine and water in a mass ratio of 1:0.01:3 to obtain monomer mixed solution D; mix water with water-soluble initiator ammonium persulfate-sulfurous acid (Hydrogen) sodium is mixed uniformly at a mass ratio of 1:0.009 to obtain an aqueous initiator solution E; at 70°C, add the aqueous initiator solution E dropwise to the monomer mixed solution D, wherein the mixed monomer solution D and the aqueous initiator E The mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com