Beam blank continuous casting secondary cooling zone cooling device

A special-shaped billet continuous casting and cooling device technology, which is applied in the field of metal continuous casting, can solve the problems of not realizing strong cooling at high temperature, increasing energy consumption, and low billet forming rate, and achieves improved billet quality, simple structure, and high cost. The effect of billet rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

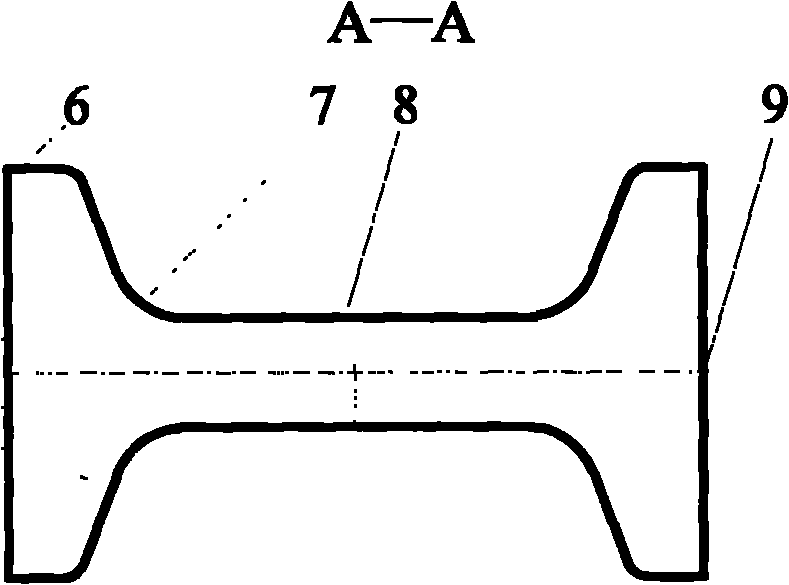

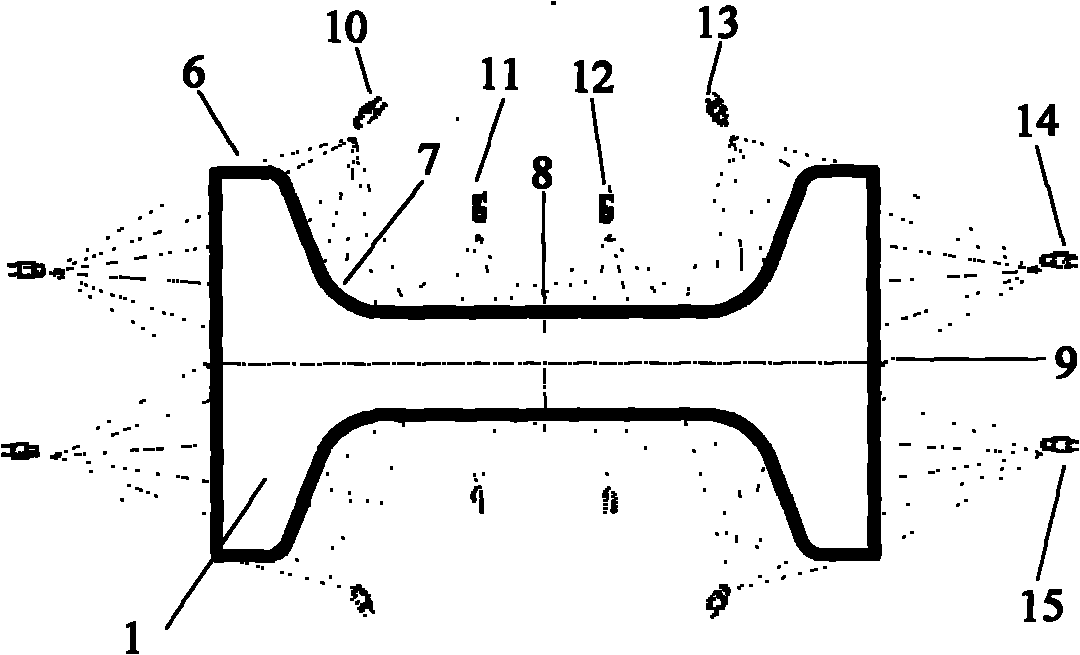

[0020] The cooling device of the present invention is used for water spray cooling in the secondary cooling zone of the shaped billet. The billet length in the second cooling zone is 6000-7500mm, the flange height is 450mm, the web width is 400mm, and the web thickness is 120mm. 1000mm, 1900-2200mm, 2800-3400mm.

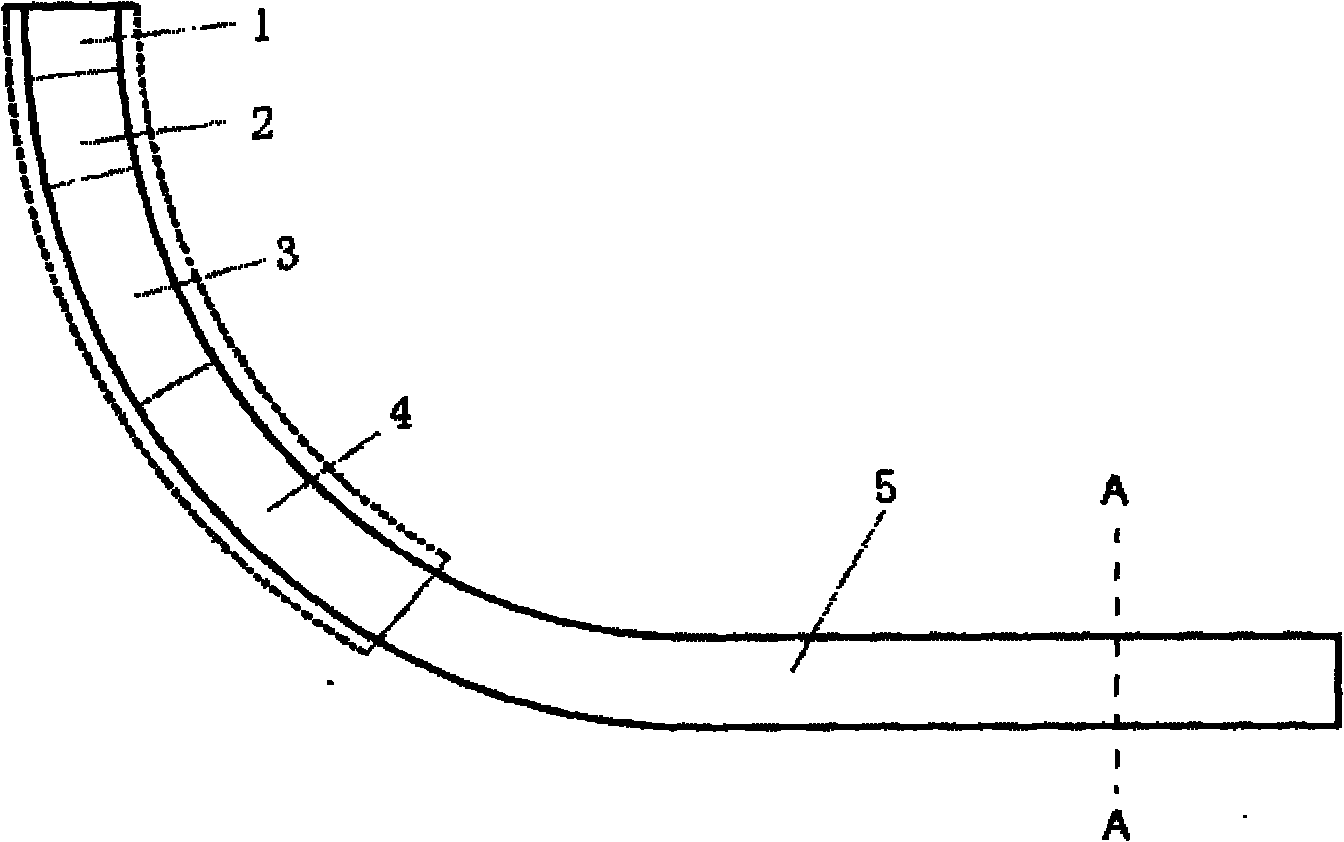

[0021] Depend on figure 1 , figure 2 It can be seen that the secondary cooling zone of the shaped billet is divided into: foot roll section, zone 1 A section, zone 1 B section, zone 2 and air cooling section, among which, the foot roll section, zone 1 A section, zone 1 B section, zone 2 Each cooling mechanism is equipped with nozzles for water spray cooling. The nozzles set by the above cooling mechanisms are connected to the water supply pipes, and the water supply pipes are fixed on the spray racks (water supply pipes, spray racks) set along the secondary cooling zone of the slab. not marked in the figure). The air cooling section is a natural cooling area. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com