Electric-driven self-pressurization rotor-type energy recovery apparatus

An energy recovery device and self-pressurization technology, which is used in fluid pressure actuation devices, fluid pressure actuation system components, seawater treatment, etc. Symmetrical arrangement and other problems, to achieve the effect of force balance, preventing mixing, overcurrent and overshoot, and reducing machining and assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

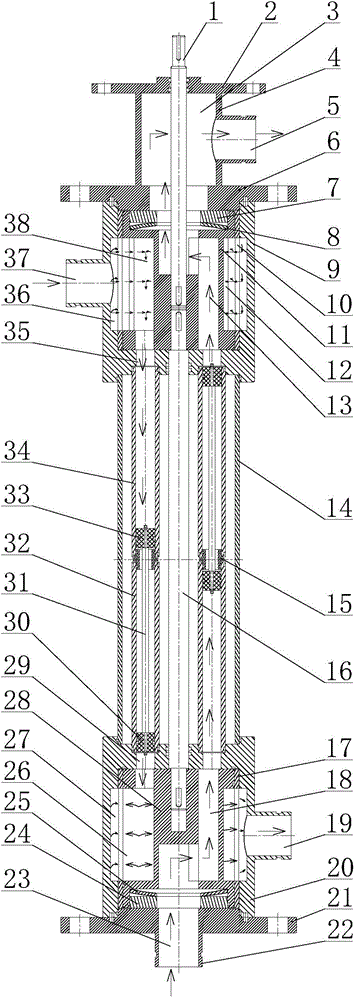

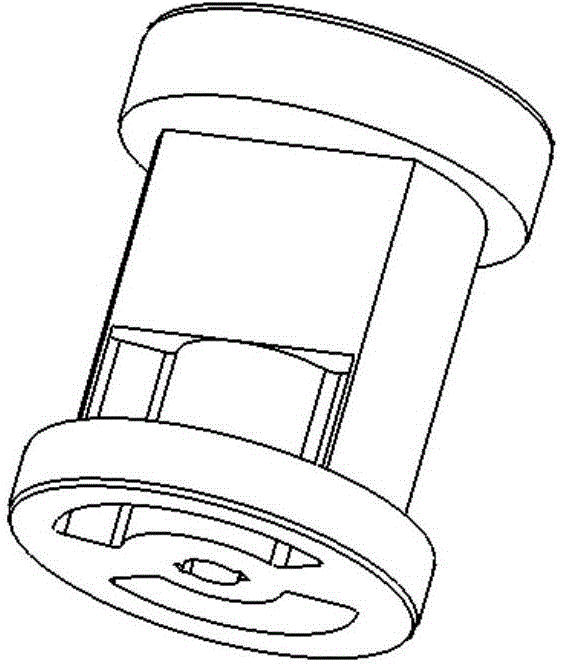

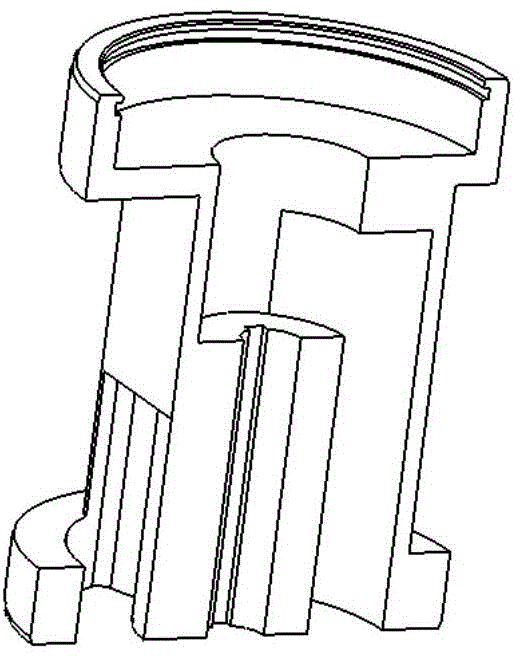

[0020] see Figure 1 to Figure 6 , an electric-driven self-supercharging rotor type energy recovery device, including a pressure relief section casing 3, a brine end casing 9, a supporting cylinder 14, a seawater end casing 20, and a low-pressure seawater interface 23, which are sequentially fixed.

[0021] The shell cylinder of the pressure relief section is provided with a motor fixing flange 2, a pressure relief cylinder 4 and a pressure relief flange 6 connected to each other, and surrounds a pressure relief brine chamber, and a pressure relief cylinder is provided on the pressure relief cylinder. The interface 5, the pressure relief brine chamber and the pressure relief interface communicate with each other.

[0022] The brine end casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com