Piston-free Stirling engine system

A Stirling engine and piston technology, which is applied to machines/engines, hot gas variable capacity engine devices, mechanical equipment, etc. Effects of Radiation Leakage Heat Loss and Acoustic Flow Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

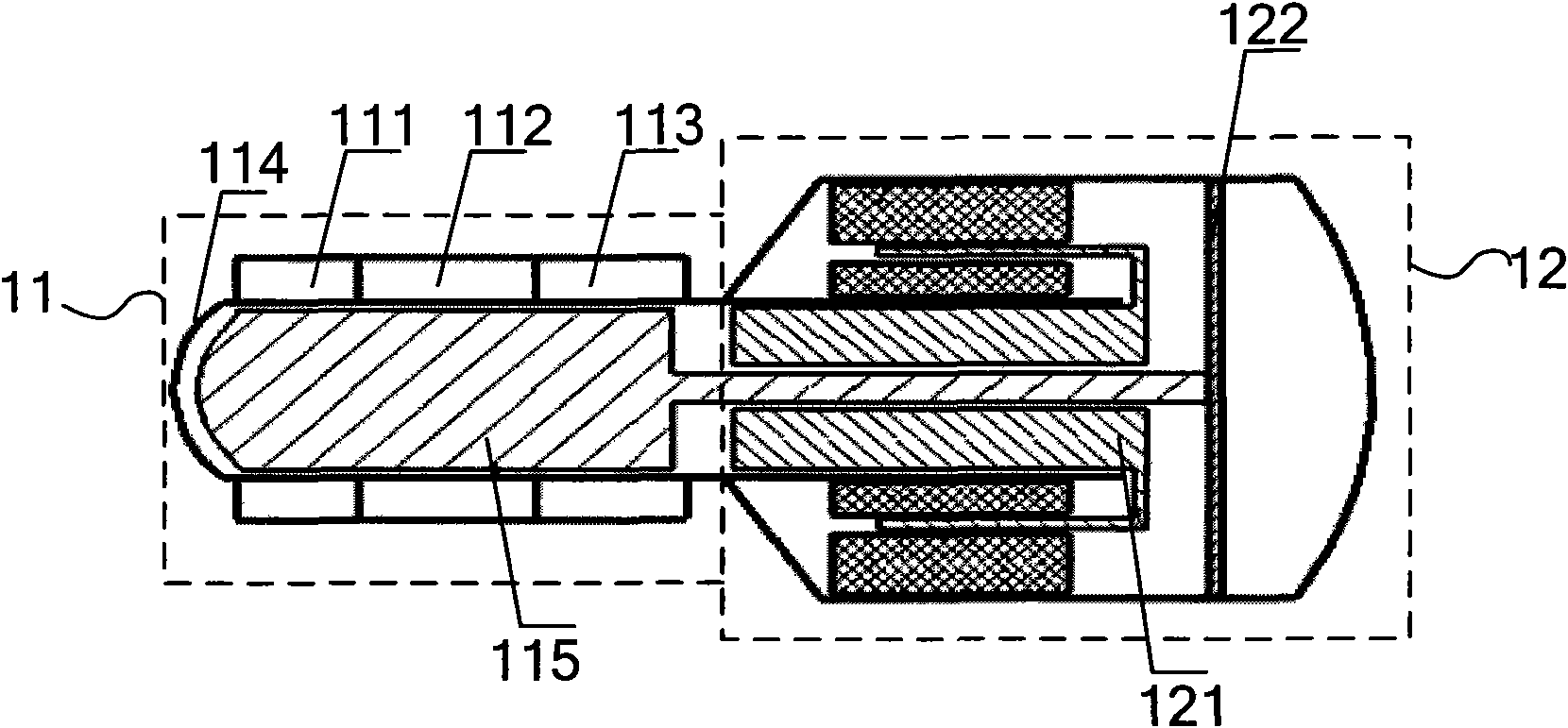

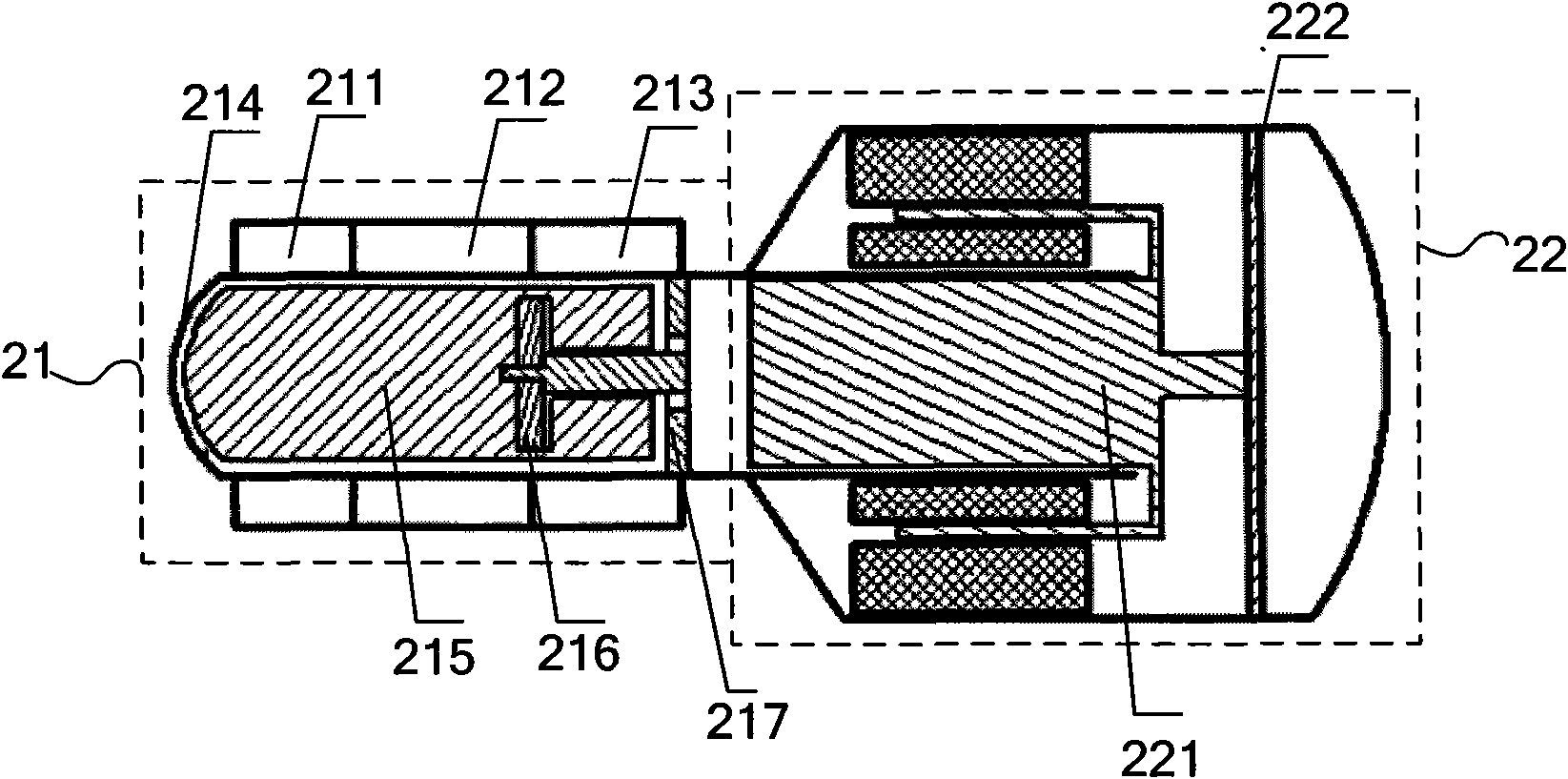

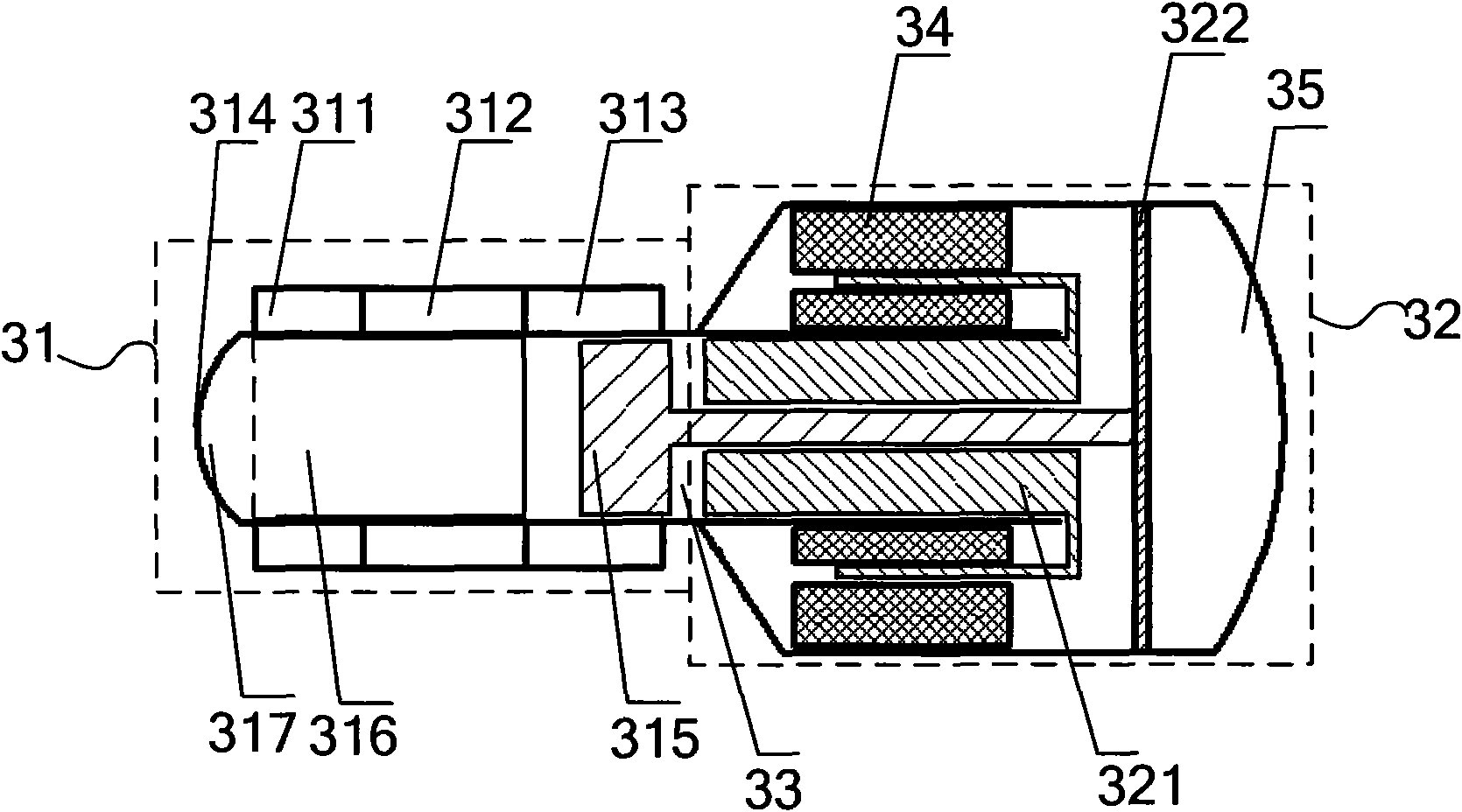

[0019] Before describing the specific implementation of the present invention, the function and working principle of the thermal buffer tube will be briefly explained.

[0020] In a free-piston Stirling engine system, the working principle of the displacer can be expressed by the following formula:

[0021] mx″=P 1 A 1 -P 2 A 2 -Kx-Rx′ (1)

[0022] Among them, m is the mass of the ejector, x is the displacement of the ejector, x' is the first-order derivative of displacement to time, that is, velocity, x" is the second-order derivative of displacement to time, that is, acceleration, P 1 and P 2 are the pressures on both sides of the high temperature end and the room temperature end of the ejector respectively, A 1 and A 2 are the cross-sectional areas on both sides of the high temperature end and the room temperature end of the ejector respectively, K is the elastic coefficient of the elastic member and the gas spring, and R is the damping coefficient. The gas spring r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com